Miter Saw Station Ideas: Compact, Mobile and Efficient

To create an effective miter saw station, focus on compact and mobile designs using 3/4″ plywood and 2×4 lumber. Include adjustable height features and implement T-tracks for cutting precision.

Smart storage solutions like drawers and vertical racks will keep your tools organized and accessible. Prioritize safety by ensuring a clear workspace and sturdy work surfaces.

Don’t forget about ergonomic features for comfort during use. Keep exploring to uncover more innovative ideas that can elevate your woodworking projects.

Key Takeaways

- Design a compact miter saw station using 3/4″ plywood and 2×4 lumber for sturdiness and mobility.

- Incorporate adjustable features for height and cutting precision, ensuring compatibility with various miter saw brands.

- Utilize innovative storage solutions like modular designs, vertical storage, and cubbyholes for efficient organization of tools and materials.

- Prioritize safety and stability by mounting the saw at waist height and keeping the workspace clear of obstructions.

- Enhance mobility with heavy-duty double-locking casters and include a high capture rate dust collection system for cleanliness.

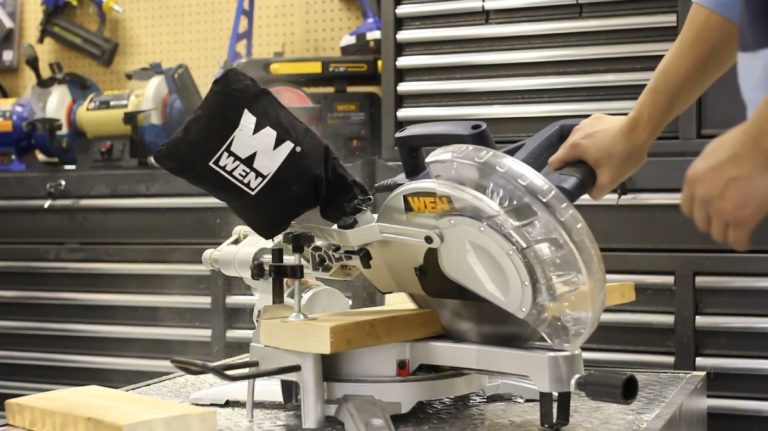

Compact and Mobile Designs

When you’re working in a limited space, designing a compact and mobile miter saw station becomes essential to your workshop’s efficiency.

Utilize materials like 3/4″ plywood and 2×4 lumber to create a sturdy yet lightweight framework. Incorporate foldable wings or extendable supports to accommodate long boards while keeping the footprint small.

Heavy-duty double-locking casters enhance mobility, allowing you to relocate the station easily when it’s not in use. Ascertain the casters have locking mechanisms to prevent unexpected movement during operation.

Additionally, consider integrating storage solutions like shelves or cabinets, maximizing functionality without sacrificing space. This design approach not only enhances workflow but also allows you to adapt your workspace to various projects seamlessly.

A strong and flat surface is essential for cutting materials accurately and safely, making it a crucial feature of your miter saw station. The inclusion of adjustable support arms will further enhance the versatility of your miter saw station, allowing for support of various workpiece lengths.

Customizable Height Adjustments

When setting up your miter saw station, consider adjustable platform designs that allow for precise height adjustments. Follow the guidelines below to ensure stability, comfort, and seamless integration with your workspace.

Adjustable Platform Designs

Adjustable platform designs for miter saw stations offer significant advantages, especially when it comes to achieving precise height adjustments tailored to your specific needs.

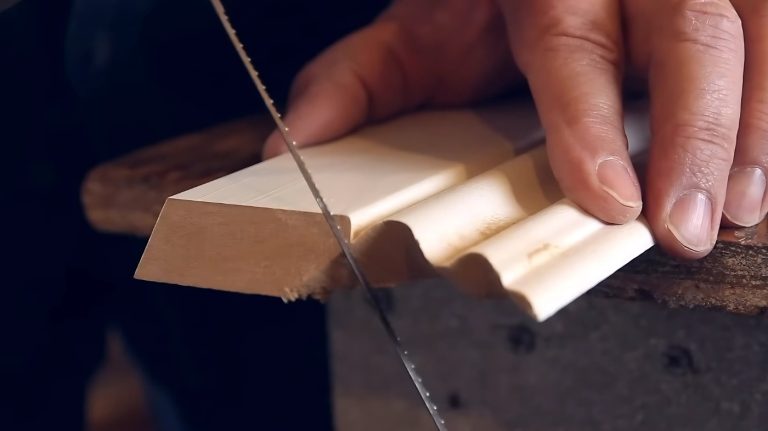

You can utilize nut and bolt adjustments to create customizable posts, allowing you to raise or lower the saw base for flush alignment. Incorporating T-tracks with adjustable stops enhances cutting precision without long fences, improving your cross-cutting accuracy.

The design also features active dust collection through a shop vacuum or dust collector, ensuring a cleaner work environment during operation. Additionally, proper setup of the stand is crucial to prevent accidents, promoting a safer workspace.

Melamine off-cuts can serve as fillers to maintain flush surfaces during upgrades. Additionally, interchangeable base plating accommodates various miter saw models, saving you the hassle of a full rebuild.

Height-Adjustable Bracket Systems

While building a miter saw station, incorporating height-adjustable bracket systems greatly enhances your workspace’s functionality.

These systems offer customization and versatility, allowing you to upgrade saw models without rebuilding your station. With micro-adjustments, you can guarantee your saw is perfectly level with the surrounding surface, vital for accurate cuts.

Additionally, the miter saw is suspended using a ceiling hanger system to ensure stability during operation. Proper alignment with optimal table height ensures that you can work comfortably and efficiently.

The durable, heavy-duty materials provide stability, making them ideal for intensive woodworking. Designed for universal compatibility, these brackets accommodate various miter saw brands.

Additionally, they enhance ergonomics by letting you adjust the workstation height to your comfort level. Their intuitive mechanisms simplify adjustments, optimizing space and assuring your saw is flush with other surfaces, ultimately increasing efficiency and improving accuracy in your projects.

Innovative Storage Solutions

When designing your miter saw station, consider integrating tool storage solutions that keep everything organized and easily accessible.

Integrated Tool Storage

Integrated tool storage in a miter saw station transforms your workspace into a streamlined hub of efficiency. By utilizing vertical tool walls, you can keep your handheld power tools readily accessible.

For instance, dowels create simple holders for tools like brad nailers and jigsaws, while customized holders can maximize storage capacity. Incorporating pegboards or hooks adds versatility to your tool wall design.

Additionally, hidden storage solutions, such as concealed pullout bins and cabinets with doors, help manage clutter while housing dust collection systems.

You can further enhance organization by integrating modular designs, allowing for easy upgrades and mobility with low-profile wheels. To optimize the storage of tools, consider using drawer slides for smooth access to your pullout drawers.

Drawer Organization Systems

A well-organized drawer system in your miter saw station can greatly enhance your workflow and efficiency. Consider adjustable compartments and removable inserts for flexible organization, accommodating various tool sizes.

Reinforced metal slides can support heavy tools, guaranteeing smooth operation and durability. Additionally, investing in a workshop drawer organizer will help keep tools and items tidy and accessible.

Proper alignment of tools is essential for maintaining accuracy during cutting tasks, so ensure that your drawer system accommodates this need. Customize your drawer layout to place frequently used tools within easy reach, maximizing accessibility.

Implement peg board systems for deep drawers, enhancing organization and visibility. Using countersunk screws guarantees secure fastening while maintaining a clean look. Additionally, modular designs allow for easy reconfiguration as your storage needs evolve.

Invest in non-slip mats to keep your items secure during operation, maintaining order and safety in your workspace. With these strategies, you’ll optimize your miter saw station effectively.

Vertical Storage Options

To maximize your miter saw station’s efficiency, consider implementing innovative vertical storage options that utilize overhead and wall space effectively.

Start by incorporating a torsion box structure for securely holding vertical panels, ensuring they’re stored at an 8-degree angle to prevent tipping. Use a 2×4 modular frame to easily integrate tool walls and T-track systems for precise cuts.

The base structure is a simple torsion box for rigidity, adding strength and stability to your design. Additionally, creating a custom storage solution can help to further organize your tools and accessories.

Adding large shelves or cabinet-enclosed designs can enhance organization while keeping your workspace tidy. For additional stability, use galvanized tubes and square stock in your support channels.

Essential Building Materials and Tools

When building a miter saw station, selecting the right materials and tools is essential for ensuring longevity and functionality.

You’ll need to gather sturdy components that can withstand the rigors of use. Here’s a quick list of essentials:

- Lumber: Use 2x4s for framing.

- Plywood: Opt for 3/4″ plywood for surfaces and cabinets.

- Poplar wood: Great for frames due to its paintability.

- MDF: Ideal for smooth drawer bottoms.

- Table saw: Vital for cutting lumber accurately, as it ensures precision and accuracy in your cuts.

Additionally, a pocket hole jig, drill press, router, and impact driver will streamline your assembly process. Including recessed fences with stop blocks will enhance your accuracy in making precise cuts.

Ergonomic and Functional Features

While designing your miter saw station, incorporating ergonomic and functional features greatly enhances both comfort and efficiency in your woodworking tasks.

Opt for miter saw handles that allow horizontal orientation when lowered, improving grip comfort. Look for palm pads on handles to reduce wrist strain during repeated plunge cuts.

A rotatable joint is essential for comfortable adjustments during angled cuts. Material quality plays a crucial role in ensuring that these ergonomic features remain durable over time.

Choose miter saw handles with horizontal orientation and palm pads for enhanced grip comfort and reduced wrist strain during cuts.

Consider a fenceless design with T-tracks for maximizing space and flexibility. Include drawers and pull-out trays for organized tool access.

Verify your work surfaces are long enough to support various cuts. Customizable features allow you to tailor the station to your saw type, optimizing both ergonomics and functionality for a smoother workflow.

Safety and Stability Considerations

Ensuring safety and stability in your miter saw station is essential for both effective operation and injury prevention.

To create a secure environment, consider these key elements:

- Blade Guards: Always check that blade guards are functioning properly.

- Secure Mounting: Mount your miter saw at waist height on a sturdy workbench. Inspect the blade guard regularly to ensure it is intact and effective. Properly secured miter saws enhance safety and cutting precision.

- Stable Base: Keep the working surface clear and stable to prevent accidents.

- Proper Footing: Maintain a stable stance to avoid slips while operating the saw.

- Hands Away from Blade: Always keep hands clear of the blade during cuts.

Creative Customization Options

Customizing your miter saw station not only enhances functionality but also tailors the workspace to your specific needs and preferences.

Consider modular and mobile designs that allow easy reconfiguration and movement between workspaces. Integrate custom storage solutions like adjustable shelving and pull-out trays for quick access to tools.

Height adjustment features make your station ergonomic, accommodating different users and tools while ensuring precise blade alignment. Additionally, current data can provide insights into the most popular features to include in your design, making it more relevant to user preferences.

Utilize innovative materials, such as butcher block tops, for durability, and add custom finishes to elevate aesthetics. Enhance your workspace with integrated dust collection systems and cable management to maintain organization and cleanliness.

Frequently Asked Questions

What Are the Best Brands for Miter Saw Stations?

When you’re selecting the best brands for miter saw stations, consider reliability and features. Original Saw Company excels in precision, while DeWalt and Bosch are known for stability and portability.

DeWalt’s DWX723 supports heavy loads and offers versatility, whereas Bosch’s T4B Gravity-Rise stands out for ease of transport. For specialized needs, check out the Saw Helper Ultrafence for extended cuts and the Trojan TWC-35 for ergonomic support.

How Much Space Is Needed for a Miter Saw Station?

You might think you need a massive workshop for a miter saw station, but that’s not true. Generally, you’ll want about 24 inches in width for the saw and 36 inches in height to match other surfaces. Depth should be around 24-30 inches for tools and storage.

Don’t forget to account for extra space on each side—about 96 inches on the left and 48 inches on the right—for handling longer materials safely.

Can I Use a Miter Saw Station Outdoors?

Yes, you can use a miter saw station outdoors, but you need to take into account several factors. First, protect your saw from weather elements like rain and sun.

Make certain the station is sturdy enough for various workpieces, and include casters for mobility. Check that your power supply is safe for outdoor use.

Finally, implement effective dust management strategies to minimize debris, as wind can complicate outdoor dust collection.

What Are Common Mistakes When Building a Miter Saw Station?

When building a miter saw station, you might overlook space planning, which can hinder comfortable operation. Make certain you provide adequate support for long boards to maintain stability.

Pay attention to saw placement for easier material handling and consider your shop layout for efficient workflow. Don’t underestimate the importance of mobility; incorporating casters can enhance flexibility.

Finally, prioritize using quality materials and proper assembly to avoid structural weaknesses and misalignment issues.

How Can I Maintain My Miter Saw Station?

Did you know that regular maintenance can extend your miter saw’s lifespan by up to 50%? To keep your miter saw station in top shape, check for wear and tear on components and lubricate moving parts frequently. Clean dust and debris regularly, and inspect the blade for dullness or damage.

Don’t forget to verify fence alignment and depth stop settings for precision. Annual thorough inspections guarantee everything operates smoothly and safely.

Enhance Your Woodworking with a Perfect Miter Saw Station

Incorporating these miter saw station ideas can revolutionize your woodworking experience, making it as smooth as a hot knife through butter. By focusing on compact designs, adjustable heights, and innovative storage, you’ll create a workspace that maximizes efficiency and safety.

Prioritizing ergonomic features not only enhances comfort but also boosts productivity. With a few creative touches, your station can become a masterpiece that transforms your projects and elevates your craftsmanship to unprecedented heights.