Left Tilt and Right Tilt Table Saw: 8 Differences

As a woodworking enthusiast, I am always fascinated by the intricate workings of table saws. And for carpenters, woodworkers, and craftsmen, choosing between right-tilt and left-tilt table saws has significant implications.

With left-tilting saws, the blade tilts to the left, reducing kickback hazards and improving access to the motor and cabinet components.

Conversely, right-tilting saws have the blade tilted to the right. It allows accurate use of the rip fence distance indicator and potential ergonomic advantages for right-handed users.

Here, I’ll dive into the differences between left-tilt and right-tilt table saws. You will come to understand the advantages and limitations of each.

8 Differences Between Left Tilt and Right Tilt Table Saw

Regarding woodworking, I’ve found that the 8 major differences between left tilt and right tilt table saws are crucial to consider.

- Bevel cutting comfort

- Blade tilt direction impact on cuts

- Motor and cabinet access

- Fence positioning and accuracy

- Arbor nut orientation

- Convenience in measurement

- Blade thickness impact and calibration

- Handling large sheets

No 01: Bevel Cutting Comfort

Based on my research, using a left-tilt table saw significantly enhances your comfort while cutting bevels due to its ergonomic design catered toward right-handed users. The left-tilt design will give you better visibility and control over the blade and workpiece during bevel cuts.

With the rip fence positioned on the right side of the blade, you can easily make precise adjustments and maintain accurate cuts. Also, left-tilt saws allow for better dust collection since dust is diverted from you to the dust port, minimizing health hazards and keeping the work area clean.

In contrast, some carpenters may favor right-tilt saws, as the right tilt allows for removing the arbor nut with the left hand. Adjusting the blade angle for bevel cuts can impact the user’s comfort. And, because the dust port is on the left side of the saw, more dust will be directed toward you when making a cut.

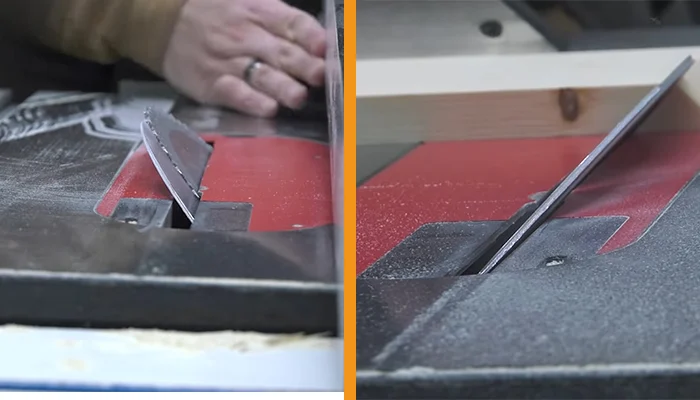

No 02: Blade Tilt Direction Impact on Cuts

I believe the blade tilt direction on left-tilt and right-tilt table saws significantly impacts the quality and safety of cuts. In left-tilt saws, the blade tilts away from the fence during cuts, which can enhance safety by reducing kickback hazards. This design feature also allows for easier error correction without substantial material loss.

Conversely, right-tilt saws have a different blade tilt direction. The blade tilts towards the fence during cuts, posing potential challenges regarding kickback hazards and error correction.

When cutting vinyl flooring with a table saw, or other floor type where splintering is a desired outcome, you should be cautious and mindful of these considerations.

No 03: Motor and Cabinet Access

I find that left-tilt saws offer better access to the motor and cabinet components on the left side. This design choice eliminates the need to reach under the right extension table, making maintenance and adjustments more convenient.

You can quickly make any necessary changes by reaching the left-side cabinet and motor components without contorting their bodies. This advantage is particularly beneficial for regular maintenance tasks, such as cleaning and lubricating the motor.

Additionally, left-tilt saws allow for easier access to the inside of the cabinet, making it simpler to inspect and repair any internal components.

Conversely, right-tilt saws may require reaching under the extension table for certain adjustments. Also, it can be difficult to access the internal components of the cabinet without taking it apart.

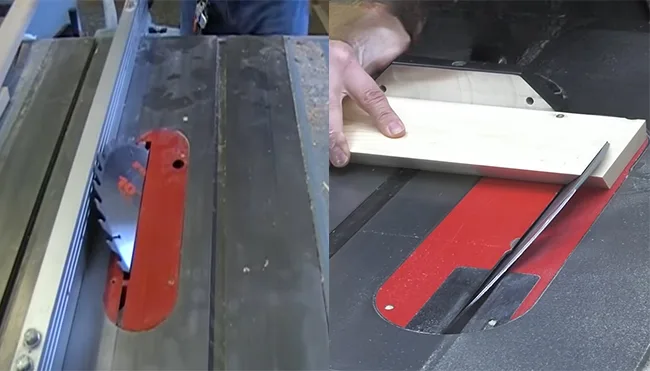

No 04: Fence Positioning and Accuracy

In left tilt saws, the fence is positioned to the right of the blade, allowing for precise and accurate cuts. This positioning also ensures the workpiece is firmly held against the fence, minimizing the chance of kickback.

On the other hand, right tilt saws have the fence positioned to the left of the blade. This can result in slightly more difficult measurements and adjustments when cutting 4×4 side lumber, as the rip fence distance indicator may not be as easy to read.

No 05: Arbor Nut Orientation

Left-tilting saws typically have an arbor nut orientation that allows the right hand to easily remove it. This design feature greatly benefits right-handed carpenters, as it enables smoother and more convenient operation.

In contrast, right-tilting saws have an arbor nut orientation that requires removal with the left hand. This may be more suitable for left-handed carpenters or those who prefer using their left hand for this task.

In my opinion, when choosing between left- and right-tilt table saws, carpenters should consider their comfort and preference and the ergonomic implications of the arbor nut.

No 06: Convenience in Measurement

Considering the convenience in measurement, the right tilt table saw offers advantages in terms of accuracy and usability with the rip fence distance indicator.

With the rip fence distance indicator located on the right side of the blade, it’s easily accessible for carpenters using their dominant hand. This allows for precise and efficient measurements, as the carpenter can easily read and adjust the distance between the blade and the rip fence.

Additionally, the design of the right tilt saw allows for accurate use of stacked dado blade sets. The rip fence distance indicator ensures that the dado blades are aligned properly, resulting in clean and accurate cuts.

However, the left tilt table saw is more difficult to use for accurate measurements because the rip fence distance indicator is on the blade’s left side. This can make it challenging for right-handed carpenters to read and adjust the rip fence distance easily.

Moreover, because the left-tilt saw requires a slightly different cutting technique than its right-tilt counterpart, I do not recommend it for beginners.

No 07: Blade Thickness Impact and Calibration

Regarding blade thickness, both left-tilt and right-tilt saws require careful consideration.

I believe changing the blade thickness can affect the saw’s cutting performance, as it alters how the wood is fed through the blade. Adjustments may be required to ensure the blade is aligned properly with the table and fence and that the angle of the blade is calibrated correctly.

In general, left-tilt saws and calibration are needed to ensure accurate and precise cutting. Carpenters need to be aware of potential adjustments required for different blade types. For example, a thicker blade may require more calibration than a thinner one.

In contrast, right-tilt saws may have different considerations regarding blade thickness changes and calibration. The right-tilt saw blades are usually set at a deeper angle than left-tilt saws, which can affect the feeding of the wood.

As such, carpenters must adjust their saw’s setup when changing blade thicknesses to ensure accuracy and safety.

No 08: Handling Large Sheets

Left-tilt saws offer advantages when dealing with larger sheets. The blade tilts away from the fence, allowing for more space on the left side of the blade. This can be beneficial when cutting large pieces.

On the other hand, right tilt saws might be more suitable for handling large sheets, as the blade tilts towards the fence. This design can provide more working room on the right side of the blade, allowing for better maneuverability and control.

I strongly suggest that to handle large sheets effectively, you must assess your workspace limitations and project requirements.

Comparison Table Between Left Tilt and Right Tilt Table Saw

| Aspect | Left-Tilt Table Saw | Right-Tilt Table Saw |

| Bevel Cutting Comfort | Better visibility and control for right-handed users. | Arbor nut removal with the left hand; potential dust directed towards the user. |

| Blade Tilt Direction Impact on Cuts | Tilt away from the fence for enhanced safety and error correction. | Tilt towards the fence, posing challenges for kickback hazards and error correction. |

| Motor and Cabinet Access | Better access to motor and cabinet components on the left side. | May require reaching under the right extension table for adjustments; harder to access cabinet components. |

| Fence Positioning and Accuracy | The fence is positioned to the right, ensuring precise and accurate cuts. | Fence positioned to the left, potentially more difficult measurements and adjustments. |

| Arbor Nut Orientation | Easily removable with the right hand, beneficial for right-handed carpenters. | Requires removal with the left hand, potentially more suitable for left-handed carpenters. |

| Convenience in Measurement | The rip fence distance indicator on the left side may be challenging for right-handed carpenters. | Rip fence distance indicator on the right side; easily accessible for precise measurements. |

| Blade Thickness Impact and Calibration | Calibration is needed for accurate cutting, especially with thicker blades. | Different considerations for blade thickness changes, with adjustments required for accuracy and safety. |

| Handling Large Sheets | Advantageous for handling larger sheets due to the blade tilting away from the fence. | May provide better maneuverability and control when handling large sheets. |

How far does a table saw tilt?

The angle range of the blade determines the maximum tilt of a table saw. Many woodworkers believe the maximum tilt of a table saw is 90 degrees, but that is not true.

According to my findings, most table saws have a maximum tilt of 45 degrees, allowing the blade to be angled either to the left or to the right. This tilt range is sufficient for various cutting tasks, including bevel and compound cuts like cutting 22.5 angles on a table saw.

However, it’s important to note that not all table saws have the same tilt range. Some models may have a smaller tilt range, typically around 30 degrees.

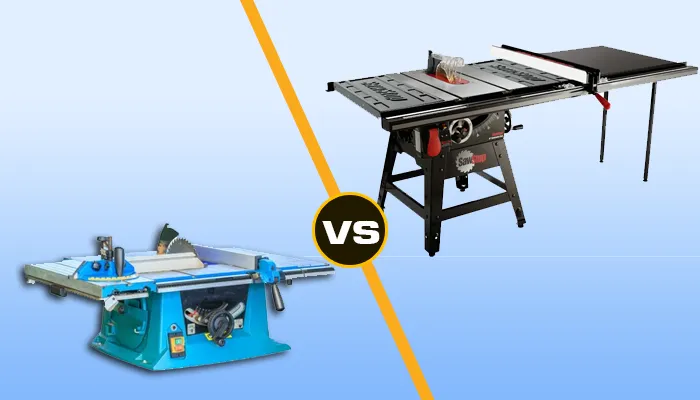

Which way does a SawStop blade tilt?

Although SawStop’s cabinet saws are left-tilt, it’s important to note that some models may have a right-tilt blade. However, most SawStop cabinet saws are designed with a left-tilt blade. This means the blade tilts to the left side of the saw’s table.

A left-tilt blade’s advantage is that it allows for safer bevel cuts. When making bevel cuts, the workpiece is pushed against the fence, preventing it from getting trapped between the blade and the fence.

Left Tilt or Right Tilt: Which Table Saw is Right for Your Woodworking Projects?

Now you can understand that the differences between left-tilt and right-tilt table saws lie in their blade tilt direction. A left tilt table saw tilts the blade to the left, while a right-tilt table saw tilts the blade to the right. The degree of tilt varies depending on the model.

Left-tilting saws offer enhanced safety and motor accessibility. The rip fence counterbalances the practical advantages of right-tilting counterparts.

In my opinion, the choice between left tilt and right tilt reflects your needs and the intricacies of the projects. So, depending on the type of cuts you’re looking to make, you’ll need to decide which table saw model ideally suits your needs.