Can I Cut PVC with a Miter Saw: 8 Steps

You have a PVC pipe that needs cutting. Then you could use a traditional hand saw, but why not take your cutting game to the next level? Enter the miter saw, a powerful and precise tool commonly used for woodworking.

With its sharp blade and adjustable angles, a miter saw is more than capable of tackling PVC pipes. Not only can it make clean, straight cuts, but it also allows for precise measurements and angles, making it ideal for projects that require accuracy.

Whether you’re a DIY enthusiast or a professional plumber, using a miter saw to cut PVC pipes can save you time and effort. But before you get started, knowing the proper techniques and safety precautions is essential.

Throughout this article, we’ll guide you through the steps of cutting PVC pipes with a miter saw, explain why a miter saw is a great choice for this task, and answer common questions like whether you can cut 4-inch PVC pipes and how fast you should cut.

Steps on How Can You Cut a PVC Pipe with a Miter Saw

Following a few simple steps will help you cut PVC pipes with a miter saw. Here’s a quick overview:

- Step 1: Safety Equipment Required

- Step 2: Choose the Right Blade

- Step 3: Adjust the Miter Saw

- Step 4: Use Cutting Fluid

- Step 5: Measure the Pipe

- Step 6: Align and Secure

- Step 7: Gently Pull the Saw

- Step 8: Smooth Rough Edges

Step 1: Safety Equipment Required

Safety equipment, like safety glasses, ear protection, dust masks or respirators, and woodworking gloves, plays a crucial role in protecting the user from harm and injury.

Eye protection glasses shield the eyes from flying debris and wood particles, preventing eye damage. The use of ear protection helps reduce the risk of hearing loss caused by the loud noise generated by power tools like miter saws.

Dust masks or respirators filter out harmful dust particles, preventing respiratory issues and ensuring clean air intake. Woodworking gloves provide a barrier between the user’s hands and sharp blades, reducing the risk of cuts and abrasions.

Wearing this safety equipment significantly minimizes the chances of accidents and promotes a safe working environment.

Here are three additional points to consider when safety is a priority:

- Inspect the PVC pipe: Carefully examine the pipe for any nails, screws, or other metal objects that could potentially damage the saw or cause accidents during the cutting process. Remove any such objects before proceeding.

- Maintain a clean workspace: Ensure that the area surrounding the miter saw is free from debris, such as sawdust or loose materials. Keeping a clean workspace will not only prevent accidents but also ensure accurate and precise cuts.

- Avoid extended use: It’s crucial to avoid using the miter saw for extended periods to prevent overheating. Allow the saw to cool down between cuts to maintain its optimal performance and prolong its lifespan.

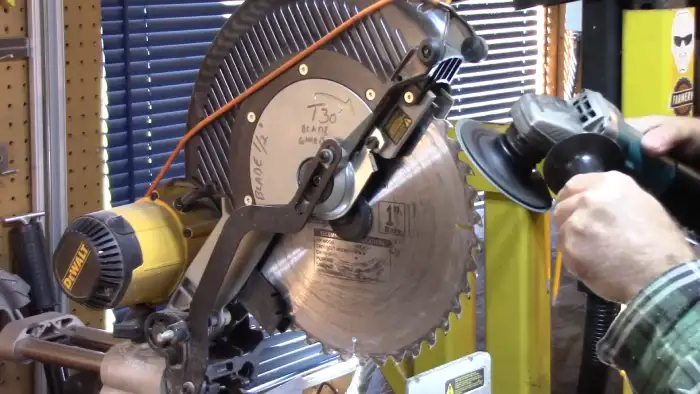

Step 2: Choose the Right Blade

Selecting the appropriate blade for plastics and similar materials is crucial to ensure precise and safe cuts, as it greatly influences the accuracy and efficiency of the cutting process. When choosing a blade for cutting PVC pipes with a miter saw, there are several key factors to consider:

- Blade Material: Opt for a blade specifically designed for cutting non-ferrous materials like PVC. These blades are usually made from carbide or high-speed steel, offering superior durability and wear resistance.

- Tooth Configuration: Multi-toothed blades are ideal for cutting PVC pipes, as they provide smoother and cleaner cuts. The teeth should have a triple-chip or alternate-top-bevel (ATB) configuration to minimize chipping and prevent the material from melting.

- Tooth Count: A blade with a higher tooth count will deliver finer and more precise cuts. A blade with 60 to 80 teeth is recommended for cutting PVC pipes to ensure smooth and accurate results.

- Blade Diameter: Choose a blade with the appropriate diameter for your miter saw. The blade should be able to comfortably cut through the thickness of the PVC pipe without any limitations.

Step 3: Adjust the Miter Saw

To achieve different cutting angles with the miter saw, simply adjust the tool accordingly, ensuring safe and efficient cuts every time. Follow these steps to adjust the miter saw for cutting PVC pipe:

- Loosen the bevel adjustment knob and tilt the saw blade to the desired angle, up to 45 degrees.

- Use the angle scale on the miter saw to accurately set the desired cutting angle.

- Ensure that the blade is securely locked in place before proceeding.

- Adjust the miter gauge to the desired angle for making crosscuts.

- Loosen the miter gauge knob and rotate it 45 degrees to the desired angle.

- Tighten the knob to lock the miter gauge in place.

Step 4: Use Cutting Fluid

Now that you have adjusted the miter saw for cutting PVC pipes, it’s time to enhance your cutting conditions by using cutting fluid. Cutting fluid, also known as lubricant, plays a crucial role in improving tool life and overall cutting performance.

By reducing friction and heat generation, cutting fluid helps prolong the life of your cutting tool and prevents it from dulling prematurely. Additionally, it aids in chip evacuation and provides a smoother cutting motion, resulting in cleaner and more precise cuts.

For cutting PVC pipes, there are various types of cutting fluids suitable for the task. These include soluble oils, synthetic fluids, and semi-synthetic fluids. The choice of cutting fluid depends on factors such as the material being cut, the cutting speed, and the desired surface finish.

Step 5: Measure the Pipe

Before diving into the cutting process, it’s crucial to ensure accurate measurements of the PVC pipe, as the saying goes, ‘Measure twice, cut once.’ Follow these steps to achieve precise measurements:

- Use a measuring tape: Start by measuring the length of the pipe from one end to the desired cutting point. Make sure the tape is aligned with the pipe’s outer edge for accuracy.

- Mark the cutting point: Once you’ve determined the correct length, use a permanent marker to mark the cutting point on the pipe. Double-check the measurement before marking to avoid errors.

- Consider the cutting blade width: Take into account the width of the cutting blade to ensure the final cut aligns with the marked point. This’ll help you achieve a clean and accurate cut.

Step 6: Align and Secure

Aligning and securing the PVC pipe correctly on the miter saw ensures stability and precision during the cutting process.

First, position the pipe on the miter saw’s base, making sure it’s flush against the saw’s fence. This alignment is crucial as it prevents the pipe from moving or shifting while cutting.

Next, use clamps to secure the pipe firmly in place. This step eliminates any potential wobbling or vibrations that could lead to inaccurate cuts. This way not only saves time but also ensures the user’s safety.

Proper alignment and securing of the pipe also minimize the risk of the pipe getting caught or jammed in the saw, reducing the chances of accidents.

Step 7: Gently Pull the Saw

With a gentle pull, the saw effortlessly glides through the PVC pipe, leaving behind flawless cuts that’ll impress even the most discerning eye. The benefits of pulling the saw down gently for clean and precise cuts are numerous:

- Reduced risk of damage: By pulling the saw down gently, you minimize the chances of the PVC pipe cracking or splintering, ensuring a smooth and intact cut.

- Enhanced precision: A gentle pull allows for better control and accuracy, enabling you to achieve precise measurements and angles for your PVC pipe cuts.

- Improved safety: Pulling the saw down gently reduces the likelihood of kickback, a dangerous and sudden backward movement of the saw, ensuring your safety during the cutting process.

Step 8: Smooth Rough Edges

To achieve a cleaner and neater finish on your PVC pipe, it is important to address the rough edges that may result from cutting. After cutting the pipe with a miter saw, the edges may be rough due to the sharp blade and the nature of the material.

Sandpaper can be used to smooth out these rough edges. Start by selecting a fine-grit sandpaper, such as 120 or 150 grit, and fold it in half. Hold the folded sandpaper with one hand and firmly grip the PVC pipe with the other.

Rub the sandpaper back and forth along the rough edges of the pipe, applying even pressure. Continue this process until the roughness is removed and the edges are smooth. To ensure a consistent finish, move the sandpaper in a circular motion.

Why Use a Miter Saw to Cut a PVC Pipe?

For cutting PVC pipes, using a miter saw offers several advantages:

- No 01: Precise Angled Cuts

- No 02: Clean, Smooth Edges

- No 03: Time-Saving Option

- No 04: Versatile Tool Choice

- No 05: Accurate Miter Joints

No 01: Precise Angled Cuts

If you want picture-perfect angled cuts, a miter saw is your go-to tool when cutting a PVC pipe. With its ability to make precise and accurate cuts at various angles, a miter saw ensures that your PVC pipe fits together seamlessly. The use of a miter saw allows for consistent and uniform cuts, resulting in a professional finish every time.

No 02: Clean, Smooth Edges

To achieve flawlessly polished edges on your PVC pipes, using a miter saw is like unleashing a magical force that transforms roughness into silkiness. Here are four reasons why a miter saw is the ultimate tool for achieving clean, smooth edges on PVC pipes:

- Precision: The miter saw’s adjustable cutting angle allows you to make precise cuts, ensuring a clean and smooth edge every time.

- Speed: Its powerful motor and sharp blade enable quick and efficient cuts, saving you time and effort.

- Control: The miter saw sturdy build and adjustable fence provide exceptional control, allowing you to guide the PVC pipe smoothly through the blade for a clean cut.

- Finishing Touch: Its sharp blade leaves a polished finish on the PVC pipe’s edge, eliminating the need for additional sanding or smoothing.

No 03: Time-Saving Option

Experience the ultimate time-saving option for achieving flawlessly polished edges on your PVC pipes by harnessing the power of a miter saw. With its sharp, high-speed blade, a miter saw can effortlessly slice through PVC, saving you valuable time and effort.

Unlike other cutting methods that may result in jagged or uneven edges, a miter saw ensures a smooth finish every time. The saw’s adjustable cutting angle and accurate measuring capabilities allow for precise cuts, ensuring that your PVC pipes fit perfectly together.

No 04: Versatile Tool Choice

A miter saw is a versatile tool that can easily handle various cutting tasks. When cutting PVC pipes, a miter saw proves to be a valuable choice. Here are four reasons why:

- Adjustable angles: With its adjustable angles, the miter saw enables you to cut PVC pipes at different angles, making it suitable for various projects.

- Efficient cutting: The miter saw powerful motor and sharp blade ensure quick and efficient cutting of PVC pipes, saving you time and effort.

- Safety features: Miter saws come with safety features, such as blade guards and automatic shut-offs, ensuring a secure cutting experience.

- Ease of use: Operating a miter saw is straightforward, allowing even beginners to cut PVC pipes with confidence and precision.

No 05: Accurate Miter Joints

A miter joint is created when two pieces of material are cut at complementary angles and joined together to form a corner. This type of joint is commonly used in woodworking and carpentry projects.

When cutting PVC pipes with a miter saw, the tool’s adjustable miter gauge allows you to precisely set the desired angle for your joint. The saw’s sharp blade and powerful motor ensure clean and precise cuts, resulting in tight and seamless miter joints.

Can you cut 4 inch PVC with a miter saw?

You can definitely use a miter saw to easily cut through a 4-inch PVC pipe, making the task quick and hassle-free. Here are three reasons why a miter saw is an ideal tool for this job:

- Power and Speed: A miter saw’s powerful motor and sharp blade allow it to effortlessly slice through the PVC pipe, saving you time and effort compared to using a manual pipe cutter.

- Clean and Accurate Cuts: The miter saw precision ensures clean and accurate cuts, resulting in smooth edges that fit together seamlessly. This is especially important when working with PVC pipes, as precise cuts are essential for proper fittings and joints.

- Handling Larger Diameters: Unlike a manual pipe cutter, a miter saw can handle larger diameters of PVC pipes. This means you can confidently work with 4-inch PVC pipes without worrying about the limitations of other cutting tools.

Should I cut the PVC pipe slowly or quickly?

To achieve the smoothest and most precise cuts, it’s best to gradually slice through the PVC pipe, allowing for greater control and ensuring a cleaner end result.

Cutting PVC pipes slowly and steadily is recommended to maintain control over the saw and prevent any potential mishaps. A miter saw can be a suitable tool for cutting PVC pipes, but it’s important to exercise caution and follow proper techniques.

By cutting slowly, you can maintain control over the saw’s movement and ensure a cleaner cut without any jagged edges or uneven surfaces. This method also reduces the risk of the PVC pipe cracking or breaking during the cutting process.

Unlock the Power and Precision of Cutting PVC Pipes with a Miter Saw

Consider using a miter saw when looking for a quick and efficient way to cut PVC pipes. Its ability to make precise cuts and angled measurements makes it an ideal tool for any DIY enthusiast or a professional plumber.

However, taking safety precautions while using the miter saw is important, such as wearing goggles and gloves. Always use the appropriate blade and follow the correct techniques to get the best results. Whether cutting a 2-inch or 4-inch PVC pipe, a miter saw can easily handle the job.

So, upgrade your cutting abilities and get ready to enjoy the precision and power of a miter saw.