Miter Saw Compound VS Sliding: Get 8 Differences

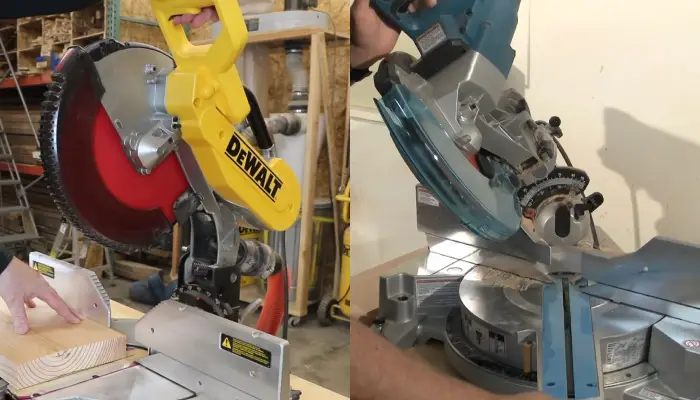

Are you ready to dive into the world of miter saws? Choosing the right tool can be like navigating a maze. In terms of miter saws, there are pros and cons to both the compound and sliding options. So which one is right for you?

Compound miter saw handles materials up to around 8 inches in width, and wider materials may require repositioning for additional cuts. In contrast, sliding miter saws can handle wider materials without needing repositioning, allowing you to work with materials twice as wide as standard compound miter saws.

Throughout this article, we’ll look at 8 main contrasts between compound and sliding miter saws to help you make an educated decision. So, let’s get started and find the perfect miter saw for your needs.

The Differences Between Miter Saw Compound vs Sliding

When comparing the miter saw compound and sliding, several key points exist. Most of them are given below:

- Cutting capacity

- Material width handling

- Horizontal motion

- Blade retention and heat

- Versatility

- Cost

- Space requirement

- Ideal users

Here is the explanation for each of the points listed above

No 01: Cutting Capacity

A typical sliding miter saw can have a cutting capacity of around 12 inches in width and 3-5 inches in depth, depending on the specific model.

The sliding miter saw offers a cutting capacity that surpasses the compound miter saw. Its sliding mechanism allows the blade to move forward and backward on rails, enabling it to cut through larger pieces of wood. This makes it ideal for projects that require cutting wider boards or crown molding.

In contrast, the compound miter saw is limited in its cutting capacity and may need help with wider materials. A compound miter saw typically has a cutting capacity of around 8-10 inches in width and 2-3 inches in depth.

The sliding miter saw’s extended reach and larger cutting capacity make it a more versatile tool for woodworking tasks involving larger and wider wood pieces.

No 02: Material Width Handling

Imagine effortlessly gliding through wider materials, effortlessly conquering any woodworking project. A sliding miter saw is the perfect tool for handling materials twice or even three times the width of a standard compound miter saw.

Its sliding feature eliminates the need for repositioning the workpiece halfway through the cut, making it more efficient for cutting wider boards and large materials.

Compound miter saws are versatile and capable of making both bevel and miter cuts at the same time, but they are limited when it comes to working with wider materials. This can lead to the need for additional support or a more complex setup to make sure you can handle the larger workpieces effectively.

No 03: Horizontal Motion

A compound miter saw is limited to a fixed arm that can be tilted to achieve angled cuts. This lack of horizontal motion capability can make cutting wider pieces of wood more difficult, resulting in the need to flip the material to complete the cut.

On the other hand, a sliding miter saw offers the ability to slide its blade forward and backward on rails, providing an extended horizontal motion range. This means that wider pieces of wood can be cut without the need for flipping or repositioning the material.

No 04: Blade Retention and Heat

The blade effortlessly glides through the material, minimizing heat retention and wear. This ensures a longer lifespan and cost-effective solution for your woodworking projects.

In a sliding miter saw, the blade’s sliding motion allows fewer teeth to engage the material while cutting. This reduced engagement results in less heat being generated during the cut and less friction on the blade itself.

Then again, the limited horizontal motion of a compound miter saw forces more teeth to engage the material. This leads to increased heat retention and wear on the blade.

The heat generated in a compound miter saw can negatively impact the cutting performance and longevity of the blade, ultimately requiring more frequent blade replacements.

No 05: Versatility

In terms of versatility, both the compound and sliding miter saw offer their own advantages. However, the sliding miter saw takes versatility to the next level with its added sliding feature. This makes it suitable for more complex projects such as pavers cutting, crown molding, and other larger-scale DIY tasks.

In contrast, the compound miter saw still offers good versatility for basic woodworking tasks, including making angled crosscuts and bevel cuts.

No 06: Cost

Compound miter saws are generally more affordable compared to sliding miter saws. They offer a wide range of cutting angles and are great for basic woodworking projects.

Meanwhile, sliding miter saws are generally more expensive due to their additional sliding mechanism. This feature allows you to easily cut larger pieces of wood, making them ideal for professional carpenters and contractors. Take your budget and specific tasks into account when weighing your options.

No 07: Space Requirement

A compound miter saw, without the sliding rails found in sliding miter saws, takes up less space overall. This makes it a great option for smaller workshops or areas with limited room.

On the other hand, a sliding miter saw’s sliding mechanism requires more space than a standard compound miter saw. This additional space is necessary for the sliding action, which allows for wider cuts. If space concerns you, a compound miter saw may be better.

No 08:Ideal Users

Compound miter saws are perfect for those new to woodworking or working on small projects. They are budget-friendly and provide basic cutting capabilities. Ideal compound miter saw users include DIY enthusiasts, hobbyist woodworkers, and those who primarily work with smaller materials.

Alternatively, sliding miter saws are more suitable for advanced woodworking projects that require larger materials and increased cutting capacity. They offer a wider range of cutting angles and can easily tackle more intricate jobs.

Ideal sliding miter saw users include professional builders, framers, and carpenters who require precision and efficiency in their work.

It’s important to note that while sliding miter saws tend to be more expensive, they offer greater versatility and are an excellent investment for those who plan to work on larger or more advanced projects.

Comparison Table Between Miter Saw Compound and Sliding

| Features | Compound Miter Saw | Sliding Miter Saw |

| Types of Cuts | Miter, Bevel | Miter, Bevel |

| Maximum Material Width | Up to 8 inches | Wider materials without repositioning |

| Sliding Feature | No | Yes |

| Heat Generation | More | Less |

| Best for | Basic woodworking tasks | Larger, advanced projects |

| Cost | Generally more affordable | Generally more expensive |

| Space Requirement | Takes up less space | Requires more space |

| Blade Engagement | More teeth engage | Fewer teeth engage |

| Suitable for | Beginners, smaller budgets | Larger materials, advanced projects |

Pros and Cons of Compound Miter Saw

One major advantage of compound miter saws is their incredible cutting versatility. They can tilt the blade to various angles, providing a wider range of cutting options. The pivoting arms of a compound miter saw allow for bevel and miter cuts, expanding the cutting arc beyond the standard 90 degrees.

This feature is especially useful for projects that require angled cuts, such as crown molding or picture frames.

But there are a few downsides:

Compound miter saws are generally more space-efficient than sliding miter saws, making them a great option for smaller workshops. Even so, you should note that compound miter saws may not handle wider materials as effectively as sliding miter saws.

They lack the sliding feature, so cutting across wide pieces of material may require repositioning the workpiece.

Pros and Cons of Sliding Miter Saw

The sliding miter saw rails enable it to cut across wide materials without repositioning. This makes it perfect for projects involving miter and bevel cuts on wide boards. Sliding miter saws can make miter and bevel cuts, offering flexibility for various projects.

If you work on big projects or require frequent cuts, a sliding miter saw can be a valuable investment due to its efficient cutting capabilities.

However, there are a couple of downsides to consider:

Sliding miter saws are more expensive than basic miter saws, making them less suitable for hobbyists or occasional DIY work. The sliding feature necessitates having more space to accommodate the backward and forward movement, making it less ideal for compact work areas.

Why is a sliding compound miter saw better?

The sliding feature of a compound miter saw provides a significant advantage in terms of increased cutting capacity. With the ability to move the blade forward and backward, you can easily make longer cuts, which is particularly useful when working with larger materials, such as wide boards or crown moldings.

This added versatility allows you to tackle various projects and achieve precise and accurate cuts. Additionally, a sliding compound miter saw provides improved stability and control, ensuring that your cuts are clean and smooth.

With its combination of compound and sliding features, this type of miter saw is the ultimate tool for precision and efficiency in woodworking tasks.

Why buy a compound miter saw?

If you want a versatile tool that can handle a wide range of cutting tasks with precision and efficiency, a compound miter saw is the way to go.

Compound miter saws offer various cutting options, making them an essential tool for any woodworker or DIY enthusiast. With the ability to make simple rips and crosscuts and angled or miter cuts up to 50 degrees on both sides, a compound miter saw allows you to tackle different projects easily.

Compound miter saws can also make angled and beveled cuts simultaneously, giving you even more flexibility in your woodworking tasks.

Whether building furniture, installing trim, or working on other woodworking projects, a compound miter saw will provide you with the accuracy and versatility you need.

What should you avoid when using a miter saw?

When using a miter saw, there are certain things you should avoid to ensure your safety.

First and foremost, never put your hand near the blade or reach around it. This can lead to serious injuries. Always wait for the blade to stop completely before making any adjustments.

Another important thing to avoid is using your hand to secure the workpiece. You should avoid this at all costs as it can be extremely dangerous.

Additionally, always remember to turn off the tool and wait for the saw blade to stop before moving the workpiece or changing any settings completely. This simple precaution can greatly reduce the risk of accidents and protect your well-being.

After every crosscut operation, return the carriage to the full rear position. This small step can significantly minimize any potential hazards and create a safer working environment.

Remember, prioritizing safety is crucial when using a miter saw. Always keep these precautions in mind to ensure your own safety and the safety of those around you.

Choose Your Perfect Miter Saw: Compound or Sliding

When choosing between a compound miter saw and a sliding miter saw, the decision ultimately rests with you.

If you are a beginner or working with smaller materials and have budget constraints, the compound miter saw might be the more suitable option. It is excellent for basic woodworking tasks, angled crosscuts, and bevel cuts while also taking up less space and being more affordable.

Conversely, if you plan to work with larger materials and undertake more advanced woodworking projects, the sliding miter saw would be a better fit. Its sliding feature allows for extended horizontal motion, accommodating wider materials without repositioning and making it ideal for larger projects and crown molding.

The reduced heat generation and wear on the blade due to fewer teeth engaging the material in a Sliding Miter Saw can be advantageous for heavy-duty applications.

Ultimately, both types of saws have their strengths and can be valuable tools in any woodworking workshop, so assessing your specific requirements is crucial to make an informed decision.