Can You Cut MDF with a Table Saw: Reveal the Truth

If you’re working on a woodworking project that requires cutting medium-density fiberboard (MDF), you might wonder if a table saw is possible. Although cutting MDF using a table saw is tough, trust me, with the appropriate blade and setup, you can do it easily.

However, some step-by-step procedures must be followed to ensure your cutting process goes smoothly and produces the desired results. When cutting MDF, using a table saw with a carbide-tipped blade is the most effective approach.

Also, the table saw should have a vacuum removal system to reduce dust and debris further. Throughout this article, I’ll guide you through cutting MDF with a table saw. Get ready to conquer your MDF projects with confidence.

How Do You Cut Mdf With a Table Saw: Steps to Follow

I’ve listed four important steps you should follow when cutting MDF with a table saw.

- Gather your tools and safety gear

- Understand your mdf

- Set up your workspace

- Execute the cutting process

Step 1: Gather Your Tools and Safety Gear

Gather the necessary tools and safety gear to begin cutting MDF with a table saw.

It’s crucial to have a reliable table saw, such as the Bosch 10′ table saw, to ensure precision and accuracy in your cuts. Also, you’ll need a carbide-tipped blade with 50-80 teeth, as this type of blade is specifically designed to handle MDF and provide clean cuts.

Don’t forget to equip yourself with the appropriate safety gear, including ear protection, safety goggles, and a dust mask except work gloves. These safety precautions are essential to protect yourself from potential injuries and harm.

Step 2: Understand Your MDF

Understanding the composition and characteristics of MDF is crucial for determining if it can be cut with a table saw.

MDF, or medium-density fiberboard, is made from wood fibers combined with resin and compressed under high pressure. It’s known for its uniform density and smooth surface, which makes it a popular choice for woodworking projects.

However, due to its high density, cutting MDF with a table saw can be challenging if not done properly. The high density of MDF requires a carbide-tipped blade with a high tooth count to ensure clean and smooth cuts.

Avoid using diamond blades, as they’re designed for different materials and may not provide the best results with MDF. For even smoother cuts, consider blades with negative hook angles.

Step 3: Set Up Your Workspace

Once you understand MDF’s composition and characteristics, you can set up your workspace to cut it with a table saw. Place a small piece of MDF board on the table to ensure stability and prevent movement during cutting. You can use clamps or adhesive tape to hold the board firmly.

Next, adjust the height of the table saw blade. For straight cuts, set the blade slightly below the surface of the MDF, around a sixteenth of an inch. This will prevent excessive dust and ensure cleaner cuts.

Step 4: Execute the Cutting Process

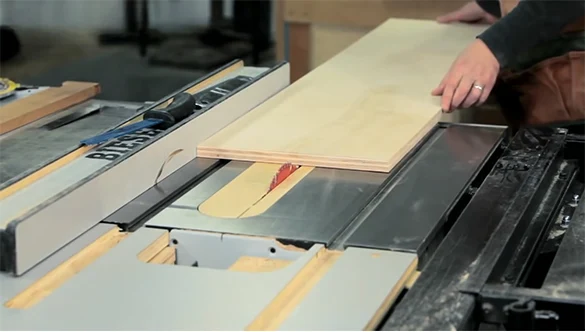

To execute the cutting process of MDF with a table saw, I advise you to carefully position the marked area on the MDF and proceed to make slow and deliberate cuts with a push block for precise results.

Firmly hold the MDF against the table saw’s fence, ensuring it’s parallel to the blade. Push the MDF through the blade with a steady grip, maintaining a consistent speed and pressure. Keeping the process slow and deliberate is crucial to achieve accurate and clean cuts.

If dealing with larger sheets, use a circular saw for initial cuts before using the table saw for the final precision cuts.

What to Consider When Cutting MDF Using a Table Saw

When cutting MDF using a table saw, several important factors must be considered.

Proper Blade Selection

I recommend using a carbide-tipped blade with 50-80 teeth per inch for cutting MDF on a table saw. This blade type is ideal for MDF because it offers durability and long-lasting performance.

The carbide tips are incredibly hard and can withstand the abrasive nature of MDF, ensuring that the blade stays sharp for a longer period. Additionally, the high tooth count on this blade provides a smoother cut, reducing the chances of tear-out and splintering.

The smaller gaps between the teeth also help prevent the MDF from chipping, resulting in cleaner and more precise cuts. When selecting a blade, it’s important to consider the specific cutting needs and choose the appropriate type (crosscut, combination, etc.) to achieve the desired results.

Cutting Techniques

When cutting MDF with a table saw, use a sharp, fine-toothed blade specifically designed for cutting MDF. This will help minimize tear-out and produce clean, smooth cuts.

Also, set the blade height correctly to match the thickness of the MDF board. This will prevent the blade from cutting too deep or not deep enough, ensuring a consistent and accurate cut.

It’s also important to feed the MDF board steadily and smoothly through the table saw, maintaining a constant speed and applying gentle pressure. This will help prevent any splintering or chipping of the MDF.

Collaboration and Assistance

To ensure a safe and efficient cutting process, consider collaboration and assistance when cutting MDF with a table saw. MDF sheets can be heavy and difficult to maneuver, especially when working alone. Seeking help from another person can provide the necessary support and stability during the cut.

This collaboration ensures that the cutting process is manageable and minimizes the risk of accidents or damage to the material. Additionally, having an extra set of eyes can help identify potential issues or obstacles during the cutting process.

Do I need a special blade to cut MDF?

To achieve clean and precise cuts, I recommend using a high-quality table saw blade specifically designed for MDF. A carbide-tipped blade with a higher tooth count, typically ranging from 50 to 80 teeth per inch, is recommended when cutting MDF.

This type of blade is designed to handle MDF’s dense and abrasive nature, ensuring smoother and more accurate cuts. The blade’s carbide tips provide excellent durability and resistance to wear, making it ideal for cutting through the dense fibers of MDF without quickly dulling.

Additionally, the higher tooth count allows for finer cuts, reducing the risk of tear-out and splintering. Investing in a specialized MDF blade will improve the quality of your cuts and prolong your blade’s lifespan.

What are the best blades for cutting MDF?

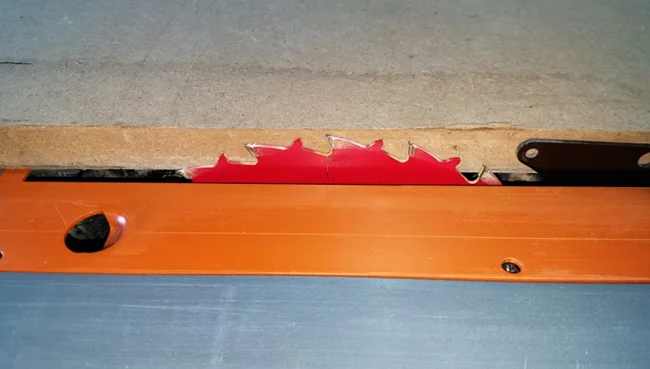

Although several options are available, the Freud LU79R010 Thin Kerf Ultimate Plywood & Melamine Saw Blade is one of the best blades for cutting MDF. This blade is specifically designed to cut through plywood, melamine, and MDF, making it ideal for woodworking projects involving MDF.

A thin kerf design reduces the amount of material that needs to be removed, resulting in faster and smoother cuts. Carbide teeth are razor-sharp and stay sharp longer, ensuring clean and precise cuts every time.

This blade also features anti-vibration slots that help reduce noise and vibration, providing a more comfortable and stable cutting experience. With its high-quality construction and cutting performance, the Freud LU79R010 is a reliable choice for ripping MDF with a table saw.

Is MDF harder to cut than wood with a table saw?

Cutting MDF with a table saw can be more challenging than cutting wood. MDF is known for its density and sturdiness, which can make it harder to work with.

Unlike natural wood, MDF doesn’t have a grain pattern, making it more consistent in its composition. However, this consistency also means that MDF is more prone to tear-out and chip-out during cutting.

The fine particles of wood fibers in MDF can easily break away, leading to rough edges and an overall lower-quality cut. To mitigate these challenges, use the appropriate blade for cutting MDF. A blade with a high tooth count and a low tooth angle will help produce cleaner and smoother cuts in MDF.

Additionally, taking your time and using a slower feed rate can help minimize tear-out and improve the quality of your cuts.

No Need to Struggle: Cut MDF With a Table Saw

After much research, I can confidently say that cutting MDF with a table saw is feasible but requires proper preparation and technique.

The most critical factor to consider when cutting MDF is using the right blade for the job. You should use a blade with a high tooth count and specifically designed to cut MDF’s sticky composition.

Adequate safety precautions and workspace set-up should also be in place to prevent injuries. Following the steps and practices for cutting MDF will result in a smooth, efficient, and precise process for your woodworking projects.