Are Circular Saw Blades Interchangeable: 6 Determining Factors

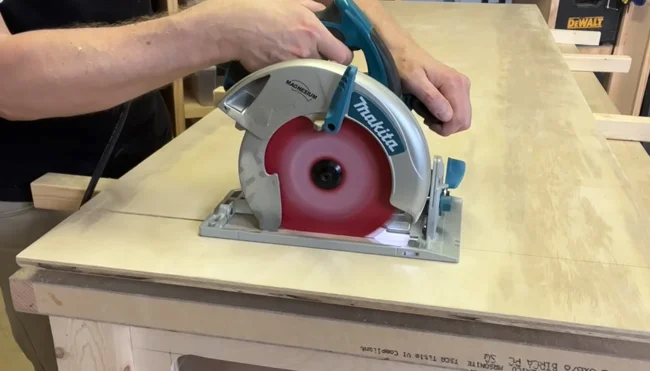

A circular saw is equipped with different types of blades for cutting wood, metal, plastic, and everything in between. A question I had before: are these circular saw blades interchangeable?

I researched this topic and found that circular saw blades are not universally interchangeable due to their varying sizes, the materials they are intended for, and the specific needs of different circular saws.

However, I also found that, under certain conditions, interchangeability is possible. Blades become interchangeable if they share the same diameter, arbor size, and possess the correct number of teeth as the saw they are intended for.

I’ll explain what factors determine the interchangeability of circular saw blades so you can make smart blade selections and ensure safe, efficient cutting.

Are Circular Saw Blades Interchangeable: Factors Determining Compatibility

When determining the interchangeability of circular saw blades, there are several factors to consider.

- Diameter and arbor size

- Cutting blade type

- Teeth configuration and tooth count

- Maximum RPM

- Kerf width

- Blade shape

Now, explore whether circular saw blades are truly interchangeable and the crucial factors that determine their interchangeability.

1. Diameter and Arbor Size

A circular saw blade’s interchangeability is determined by the size of both its diameter and arbor. The diameter of the blade is a crucial factor, as it must match the specifications of your saw.

If the blade’s diameter is too large or too small for your saw, it won’t fit properly and may compromise the safety and effectiveness of your cutting.

Additionally, the arbor size is equally important. Circular saws have arbors of varying sizes, and the blade must have an arbor size that matches your saw’s specifications. Using a blade with the wrong arbor size can result in improper attachment and potential accidents.

Furthermore, it’s important to note that circular blades can be used interchangeably with miter saws and table saws as long as their diameters and arbor sizes match.

Therefore, ensuring that the diameter and arbor size of the blade align with your saw’s requirements is vital for proper interchangeability.

2. Cutting Blade Type

The type of material you intend to cut plays a significant role in interchangeability. Circular saw blades are designed for specific materials such as wood, masonry, and even cutting through metal or concrete. It’s crucial to use the appropriate blade type for the material you’re working with.

For example, using a wood-cutting blade on a metal-cutting saw can result in poor performance and potential damage to the blade and saw. To ensure the interchangeability of circular saw blades, it’s essential to match the blade type with the material being cut.

Selecting the correct blade type will optimize cutting efficiency and produce clean, precise cuts. Always refer to the manufacturer’s recommendations for blade type compatibility to ensure safe and effective operation.

3. Teeth Configuration and Tooth Count

Considering the tooth configuration and tooth count is crucial for determining the interchangeability of circular saw blades. Circular saw blades can have different tooth configurations, such as rip, crosscut, combination, and others. Each configuration is designed for specific cutting tasks.

For example, rip blades have fewer teeth and are ideal for cutting along the grain of the wood, resulting in faster but rougher cuts. On the other hand, crosscut blades have more teeth and are better suited for cutting across the grain, resulting in slower but smoother cuts.

The tooth count on the blade also affects the quality and speed of the cut. Blades with fewer teeth are better for faster but rougher cuts, while more teeth result in slower but smoother cuts.

To ensure efficient and safe cutting, it’s essential to use the right blade type and tooth count that matches the desired cutting task.

4. Maximum RPM

Ensure that the maximum RPM rating of your circular saw blade matches or is lower than your saw’s maximum RPM. The maximum RPM rating of a circular saw blade is determined by factors such as the blade’s diameter and the material it’s made of.

Using a blade with a higher RPM rating than your saw can lead to excessive vibration, increased risk of blade breakage, and potential harm to both the operator and the material being cut. On the other hand, using a blade with a lower RPM rating than your saw may result in decreased cutting speed and efficiency.

Properly maintained and used in accordance with their specifications, circular saw blades can last through numerous projects, providing consistent performance and quality cuts.

5. Kerf Width

Another factor that determines interchangeability is the kerf width, which refers to the width of the cut made by the blade. Different saws are designed for specific kerf widths, so it’s crucial to use a blade that matches your saw’s capabilities.

Using a blade with the wrong kerf width can lead to issues such as binding or ineffective cutting. To ensure interchangeability, it’s essential to select a blade with a kerf width that’s compatible with your saw.

This will allow the blade to fit snugly and cut efficiently, resulting in precise and accurate cuts. Always refer to the manufacturer’s guidelines to determine the appropriate kerf width for your saw.

6. Blade Shape

To determine the interchangeability of circular saw blades, you need to consider the blade shape. Circular saw blades can come in various shapes, such as flat-top grind (FTG), alternate top bevel (ATB), combination ATBR, and triple-chip grind (TCG).

Each blade shape is designed for specific cutting needs and saw types. The blade shape affects the type of cuts it’s best suited for. For example, a flat-top grind (FTG) blade is ideal for ripping, while an alternate-top bevel (ATB) blade is better for crosscutting.

Ensure that you match the blade shape to your cutting needs and saw type to facilitate blade interchangeability.

What are the available sizes for circular saw blades?

Circular saw blades come in a variety of sizes to suit different types of saws and cutting applications. The most common sizes are 6-1/2 inches, 7-1/4 inches, 10 inches, and 12 inches, with the 7-1/4-inch size typically used for handheld saws and larger sizes employed in stationary circular saws.

Blades with diameters ranging from 3-3/8 inches up to 16 inches can also be found on the market, catering to a wide range of cutting needs and saw types. When you need to change your circular saw blade, it’s essential to select the right size and type that matches your saw and the materials you’ll be cutting.

Handheld circular saws typically accept blades ranging from 4-1/2 inches to 7-1/4 inches in diameter, while tile saws most commonly use 7-inch or 10-inch diamond blades.

As a general rule, larger saw blade diameters are associated with larger arbor holes, and carbide-tipped teeth are used for extended sharpness.

How many teeth are typically found on a circular saw blade?

The number of teeth on a circular saw blade generally varies depending on its type and size. For combination blades, which are versatile and suitable for various cuts, you can expect to find 10-inch blades with around 50 teeth and 12-inch blades with approximately 60 teeth.

Ripping blades, on the other hand, designed for cutting along the wood grain, usually come with 10-inch blades having 24-30 teeth and 12-inch blades with 40 or fewer teeth.

To maintain the performance and longevity of your circular saw blades, consider using a circular saw blade sharpener. Sharpening your blades periodically can extend their lifespan and keep them in optimal cutting condition, saving you money and ensuring consistently high-quality cuts.

Carefully Interchange Your Circular Saw Blades Based on Saw Requirements

Circular saw blades are indeed interchangeable, but several factors determine their compatibility that I’ve shared with you. Considering diameter and arbor size, choosing the right tooth count, RPM compatibility, kerf width, and blade shape are all important for blade interchangeability.

However, it’s crucial to avoid circular saw misuse, as using the wrong blade type or size for a particular task can lead to poor performance, potential accidents, and damage to both the blade and saw.

Selecting the proper blade, aligned with your specific saw’s requirements, ensures safe, efficient cutting results. Now armed with this knowledge, you can confidently choose the correct circular saw blade, optimizing your cutting tasks with precision and safety in mind.