How Often Should You Change a Circular Saw Blade: 4 Influencing Factors

When you cut your woodworking materials with a circular saw, the saw blade becomes loose and starts to lose its sharpness. This can lead to slow cuts, mid-cut binding, and burning wood, making achieving clean, accurate cuts challenging. As a result, it’s essential to know when to replace your circular saw blade.

Based on my research, a circular saw blade can generally last for up to 800 to 1,000 cuts before it needs sharpening. However, the duration of a saw blade’s service life depends on several factors, such as the frequency of usage, blade quality, and more.

I will explain what factors influence when to replace a circular saw blade and how to tell if the blade is dull.

How Often Should You Change a Circular Saw Blade: Factors Affecting Replacement Frequency

Several factors determine the frequency with which you should replace a circular saw blade, such as:

- Blade type and quality

- Material cut

- Frequency of use

- Blade storage

Examine in detail each factor affecting the frequency with which a circular saw blade should be changed.

1. Blade Type and Quality

Circular saw blade replacement frequency is correlated with the type and quality of blades. Carbide-tipped blades, known for their durability, can endure 800 to 1,000 cuts before needing sharpening. Tooth count, the material used, and maintenance influence their lifespan.

Steel-tipped blades, although cheaper, are less durable and require regular sharpening. Diamond-edged blades, designed for masonry, need replacement when the diamond coating wears off.

Investing in high-quality blades, especially those with carbide tips, can extend their lifespan. I found that some users have reported using carbide blades for over a decade without replacement or sharpening.

Professional-grade blades with specialized coatings, like titanium nitride, offer increased durability. Consider blades with advanced coatings for enhanced resistance to wear and a longer lifespan.

2. Material Cut

The material being cut significantly determines how frequently you should replace your old circular saw blade with a new one. Different materials have varying levels of hardness and abrasiveness, which can impact the blade’s lifespan.

When cutting wood, softer woods may not wear out the blade as quickly as harder ones. Opting for quality blades and coatings like titanium nitride can enhance durability.

Using carbide-tipped blades when cutting metal, particularly light-gauge metal, is possible, but this can reduce the blade’s lifespan. Masonry materials like concrete and brick are highly abrasive, and using diamond-edged blades designed for these materials is recommended.

However, it’s important to note that the abrasive nature of masonry materials can wear down the blade faster.

3. Frequency of Use

The frequency of use also plays a significant role in the lifespan of your circular saw blade. If you use your saw frequently for professional purposes, the blade may wear out faster than occasional or DIY use. Professional use involves more cutting, which puts more strain on the blade and causes it to wear down more quickly.

On the other hand, occasional or DIY use may extend the blade’s lifespan, but regular inspections are still necessary to ensure its performance and safety. Regardless of your frequency of use, it’s important to monitor the condition of the blade regularly and replace it when signs of wear and tear become evident.

4. Blade Storage

How you store your circular saw blades can also influence their lifespan. Moisture and humidity can cause corrosion and rust, degrading the blade’s cutting performance. Extreme temperatures can also affect the blade’s hardness and durability.

Store your saw blades in a clean, dry area away from any moisture or heat sources to protect them. Use a blade storage case or rack to keep them organized and protected. Avoid stacking blades on top of each other, as this can lead to chipping or bending.

How Do You Identify When a Circular Saw Blade Is Dull?

There are several key points to consider to determine whether a circular saw blade is dull.

1. Effort Required for Cuts

If you’re exerting more force than usual or your saw is struggling through the material, it’s a clear sign that your circular saw blade may be dull. When a blade is sharp, it effortlessly cuts through the material with minimal effort. However, as the blade becomes dull, it requires more force to make the same cuts.

This increase in effort can be felt as you push the saw through the material. The dull blade struggles to bite into the material, resulting in a slower and less efficient cutting process. It’s important to pay attention to this change in effort, as using a dull blade reduces the quality of your cuts and increases the risk of accidents.

2. Binding and Chipping

You can check whether your circular saw blade is dull by checking for signs of binding or chipping during the cutting process. If the blade isn’t smoothly progressing through the material and encounters resistance or irregularities, the blade has likely become dull.

Binding occurs when the blade gets stuck or jammed in the material, causing it to seize or stop cutting. On the other hand, chipping refers to the blade creating rough or jagged edges on the material being cut.

Both binding and chipping indicate that the blade is no longer sharp enough to cut efficiently. If you notice these signs during your cuts, it’s time to replace the blade.

3. Burning Smell During Cuts

When experiencing a burning smell during cuts, it’s clear that your circular saw blade has become dull and is struggling to make clean cuts. This burning smell is a distinct indicator of excessive friction and heat generated by the blade.

As the blade becomes dull, it loses its sharpness and efficiency, increasing friction with the cut material. This friction produces heat, causing a burning smell. Please note that the same signs also apply to a miter saw.

Ignoring these indicators can lead to further damage, such as binding and chipping of the blade in both circular and miter saws.

4. Blade Surface Condition

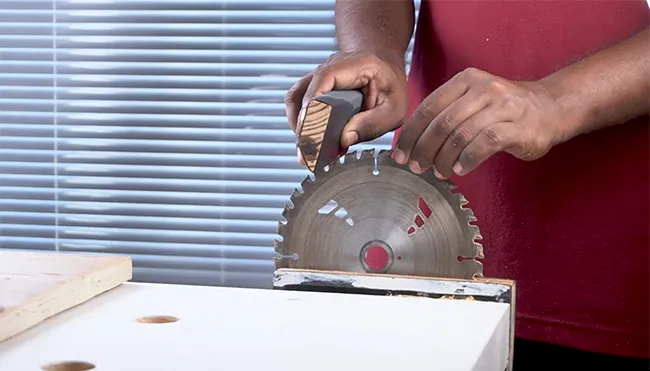

Examine the condition of the blade surface to determine if your circular saw blade is dull. For carbide-tipped or steel-tipped blades, a smooth blade surface can indicate dullness.

A sharp blade should have a slightly textured surface, and any deviation from this may indicate the need for maintenance or replacement.

Pay close attention to any signs of wear or damage on the blade. Look for any chipped or missing carbide teeth, which can affect the cutting performance. Additionally, check for any discoloration or burn marks on the blade surface, which can be indications of overheating.

If you notice any of these issues, replacing the blade is recommended to ensure optimal performance and safety. Regularly inspecting the blade surface condition is crucial for efficient and accurate cutting.

5. Unusual Motor Noises

If you notice your circular saw’s motor working harder or producing loud noises, it may be a sign that your blade is dull and needs replacement. Unusual motor noises are a common indicator of a struggling motor due to a dull blade.

When a circular saw blade becomes dull, it requires more effort from the motor to cut through material, resulting in increased strain and noise production. As the blade loses its sharpness, it can cause the motor to work harder and generate louder noises during operation.

Ignoring these signs can lead to further damage, potentially affecting the motor’s performance and lifespan. Therefore, if you experience unusual motor noises, it’s essential to inspect your circular saw blade and consider replacing it to maintain optimal cutting efficiency and prolong the life of your saw.

How do you clean a circular saw blade to extend its lifespan?

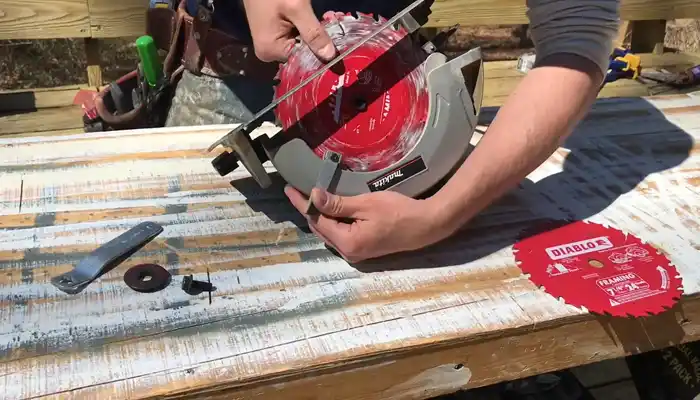

To effectively clean a circular saw blade and extend its lifespan, first remove it from the saw to ensure safety. Then, soak the blade in a cleaning solution or a mixture of warm water and mild dish soap. Ensure the blade is fully submerged for optimal cleaning.

Use a soft brush to remove any debris, pitch, or resin, focusing on the teeth and gullets. Rinse the blade thoroughly and let it dry completely before reattaching to the saw.

What is the maximum number of times a circular saw blade can be sharpened?

Circular saw blades can typically be sharpened up to three times before they need to be replaced. During sharpening, material is removed from the teeth to restore their cutting edge.

However, with each sharpening session, the size of the teeth gradually reduces, which can affect the blade’s efficiency over time. After three sharpening cycles, the blade may have undergone enough wear and alteration that its performance diminishes significantly. At this point, investing in a new, sharper blade becomes more practical for optimal cutting results.

It’s important to note that the number of times a circular saw blade can be sharpened may vary depending on the blade’s initial quality and the user’s sharpening technique.

Using a standard quality circular saw blade sharpener can contribute to maintaining the blade’s effectiveness during the sharpening process.

Timely Replace Your Circular Saw Blade for Safe and Efficient Woodworking

Changing a circular saw blade is crucial to maintaining efficient and safe woodworking. By understanding the influencing factors that I’ve shared with you, such as blade type, material cut, frequency of use, and proper storage, you can make informed decisions about when to replace your blade.

Regular inspections for dullness, such as increased effort for cuts and unusual motor noises, ensure timely replacements, preventing compromised cutting quality. Based on my market analysis, I can say that your woodworking endeavors will be more successful if you invest in high-quality saw blades and follow proper maintenance practices.