Can You Cut Drywall With a Circular Saw: 6 Reasons to Avoid

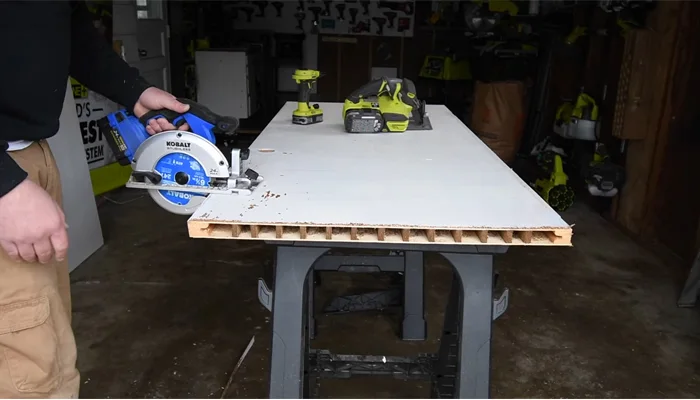

Cutting drywall is a necessary task for anyone who’s ever remodeled a room or hung new drywall. While there are many ways to approach this task, one question often arises is whether you can use a circular saw for cutting your drywall.

Based on my findings, cutting drywall with a circular saw is possible, but most experts advise against it due to the mess and safety hazards it poses. Circular saws tend to generate large amounts of dust, which can cause health problems, and there’s also a risk of damaging hidden elements behind the drywall.

I will discuss in detail why you need to avoid using a circular saw for cutting drywall so that you can understand the risks involved.

Cutting Drywall With a Circular Saw: 6 Compelling Reasons to Avoid

I found several reasons why circular saws shouldn’t be used to cut drywall, including:

- Excessive dust generation

- Potential for hidden element damage

- Blade wear and short lifespan

- Inferior edge quality

- Risk of over-cutting

- Limited maneuverability

1. Excessive Dust Generation

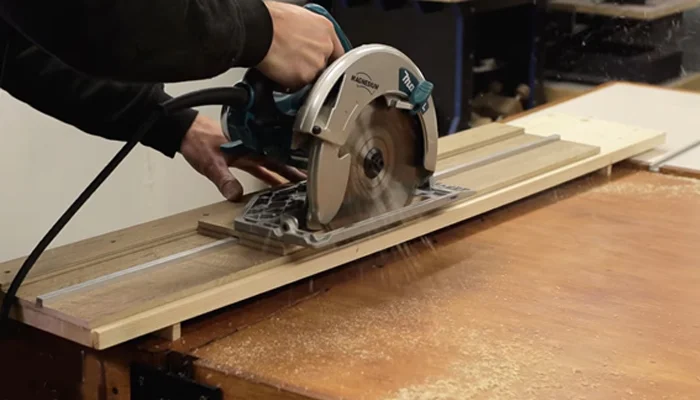

When a circular saw is used on drywall, it creates a significant amount of dust that spreads throughout the surrounding area. This dust consists of fine particles that can easily become airborne and be inhaled by those nearby. Inhaling this dust can lead to respiratory issues and other health problems.

Additionally, the dust settles on surfaces, making them difficult to clean and potentially causing damage to electronic equipment. The excessive dust generation from using a circular saw on drywall poses health risks and creates a messy and potentially hazardous work environment.

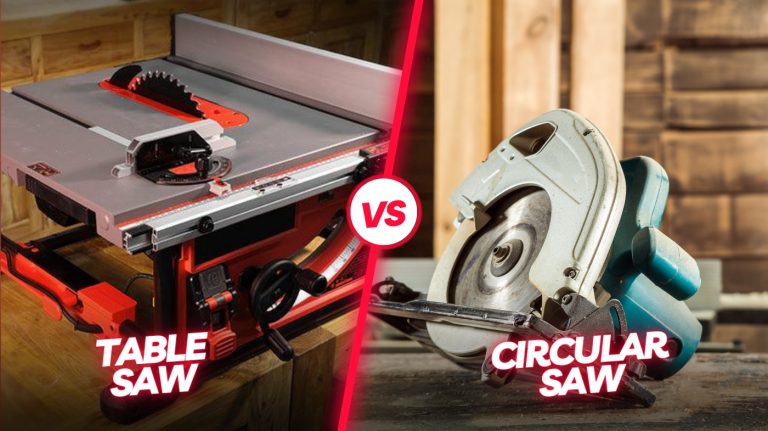

The concerns about dust generation apply not only to circular saws but also to table saws when cutting drywall. When you cut drywall with a table saw, the dust is more concentrated in one area and can be kicked up into the air even more.

Therefore, it’s advisable to use alternative methods for cutting drywall that minimize dust production.

2. Potential for Hidden Element Damage

If you use a circular saw on drywall that’s already installed, you’re more likely to reach hidden elements, such as wires and pipes behind the wall. The blades of circular saws, especially those with long blades, may extend beyond the thickness of the drywall, making it likely to reach concealed infrastructure unintentionally.

This danger is particularly significant when cutting into walls or ceilings, with a higher potential for reaching hidden elements. It’s crucial to recognize that damaging electrical wiring or plumbing can have severe consequences, including electrical shocks, short circuits, or water leaks.

Professionals strongly discourage the use of a circular saw for cutting drywall after installation to ensure safety and prevent costly damages.

Instead, opting for tools specifically designed for drywall cutting, such as drywall saws, reciprocating saws, or utility knives, minimizes the risk of reaching hidden elements and guarantees a safer cutting process.

3. Blade Wear and Short Lifespan

Using a circular saw to cut drywall can lead to accelerated blade wear and a significantly shorter lifespan. Drywall’s abrasive nature and gypsum core can quickly dull the blades, resulting in the need for frequent replacements. This not only adds to the overall cost but also causes inconvenience.

The abrasive properties of drywall cause the blade teeth to wear down rapidly, reducing their cutting efficiency. As the blade becomes dull, it requires more force to cut through the drywall, increasing the risk of kickbacks and accidents.

Additionally, the dust and debris generated during the cutting process further contribute to blade wear since they get stuck in the teeth. Therefore, it isn’t recommended to use a circular saw for cutting drywall due to the accelerated blade wear and short lifespan it entails.

4. Inferior Edge Quality

The edges are often left rough and uneven when using a circular saw to cut drywall. Instead of making a clean cut, the saw’s blade tears through the material, leaving jagged edges. The issues with edge quality persist with both regular circular saws and rear-handle circular saws when cutting drywall.

This inferior edge quality can be particularly problematic when trying to achieve a smooth and seamless finish, as it may require extra sanding, patching, or even the use of a joint compound to achieve the desired result.

The imprecise nature of a circular saw’s cut can also lead to inconsistencies in the dimensions of the drywall, making it more difficult to achieve a tight and accurate fit during installation.

5. Risk of Over-Cutting

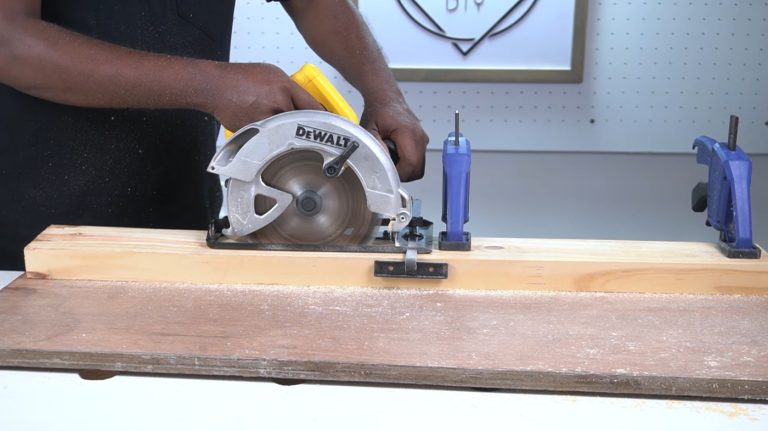

Circular saws are powerful tools with fast-spinning blades that can easily remove excess material, leading to irregularities in the cut. The risk of over-cutting is particularly high for those who aren’t experienced with the tool.

When using a circular saw on drywall, there’s a chance of cutting too deeply or veering off course, resulting in a less precise and clean cut. This can create additional work to rectify the mistakes, such as patching or replacing the damaged portion of the drywall.

6. Limited Maneuverability

Circular saws are great for cutting through large sections of drywall, but they’re bulky and hard to maneuver in tight spots. Trying to navigate a circular saw in these situations can result in inaccurate cuts and potential damage to surrounding areas.

The larger blade size and the need for a stable cutting platform can also make it challenging to make intricate or detailed cuts, such as around electrical outlets or plumbing fixtures.

Can you minimize dust production when cutting drywall with a circular saw?

You can reduce dust production when cutting drywall with a circular saw. One way to do this is using a circular saw equipped with a dust extraction attachment to capture and contain airborne particles.

Working in a well-ventilated area or using a fan to direct dust away from the immediate work zone is also important. Maintaining a sharp blade is also crucial to minimizing dust production when cutting drywall with a circular saw.

A sharp blade cuts through the material more efficiently, reducing the amount of friction and resistance encountered during the cutting process. This, in turn, can contribute to a cleaner cut and less dust generation.

To ensure your circular saw blade stays sharp, regularly use a good-quality circular saw blade sharpener. Keeping the blade sharp not only improves the cutting performance but also extends the blade’s life.

Additionally, wearing a dust mask or respirator will protect you from inhaling fine particles. Organizing your workspace and cleaning up dust regularly will reduce overall dust production, creating a cleaner and safer environment for your work.

Can you cut curves in drywall using a circular saw?

It’s not advisable to use a circular saw to cut curves in drywall. Circular saws are not designed for curved cuts, and attempting to do so may result in imprecise cuts and potential damage to the drywall.

It is best to use a specialized tool such as a jigsaw or a drywall saw to achieve precise and clean curved cuts. These tools are specifically designed for curved cuts and provide the necessary control and precision required for the job.

Avoid Using Circular Saws for Drywall Cutting and Optimize Your Project Outcome

I hope you now understand the reasons to avoid cutting drywall with a circular saw. From excessive dust generation to the potential for hidden element damage, using a circular saw poses significant challenges in achieving clean, precise cuts.

The risk of over-cutting, limited maneuverability, and inferior edge quality further emphasize the importance of opting for specialized tools when working with drywall.

Prioritizing safety, minimizing drywall dust production mess, and ensuring efficient, high-quality results are key considerations in any drywall cutting project. Choose the right tools wisely to enhance both the process and the final outcome of your drywall installation or remodeling task.