What Is a Worm Drive Saw? Key Features You Should Know

A worm drive saw uses a worm gear to deliver high torque, making it perfect for cutting dense materials like thick lumber.

You’ll find the motor at the rear, driving the blade through a 90-degree gear setup, which boosts power and precision. Its blade sits on the left side, improving visibility and control, especially for right-handed users.

This design also offers better durability and stability for heavy-duty jobs. Keep going, and you’ll discover how it stacks up against other saws and fits into tough woodworking tasks.

Key Takeaways

- A worm drive saw uses a worm gear mechanism to transfer motor power at a 90-degree angle to the blade, providing high torque and slower blade speed.

- It features a rear-mounted motor and left-positioned blade, improving cut line visibility and precision for right-handed users.

- The worm gear system includes hardened steel worm and bronze or cast iron worm wheel, supported by tapered roller bearings for durability.

- Worm drive saws offer greater torque and stability, making them ideal for heavy-duty cutting like framing, thick lumber, and dense materials.

- Their enclosed metal housing protects gears from dust and wear, requiring regular lubrication but ensuring longer lifespan and reduced maintenance.

Definition and Basic Principles of Worm Drive Saws

Although worm drive saws might look similar to standard circular saws, they operate on a distinct mechanism that sets them apart.

Worm drive saws resemble standard circular saws but feature a unique internal mechanism.

In a worm drive saw, power transfers from the motor to the blade via a worm gear system, positioned at a 90-degree angle.

This means the motor sits at the rear, separated from the blade by the worm gear, which converts the motor’s rotation into slower blade speed but higher torque.

The worm gear consists of a screw-like worm meshing with a worm wheel, providing significant speed reduction and torque multiplication.

This setup delivers powerful, controlled cuts, making worm drive saws ideal for heavy-duty construction tasks where cutting through thick or dense materials is necessary. The rear handle design of many worm drive saws also provides enhanced control and leverage for precise and stable cutting.

The gear ratio of the worm gear drive is determined by the number of teeth on the worm wheel relative to the worm, allowing for precise control over torque and speed (reduction ratio).

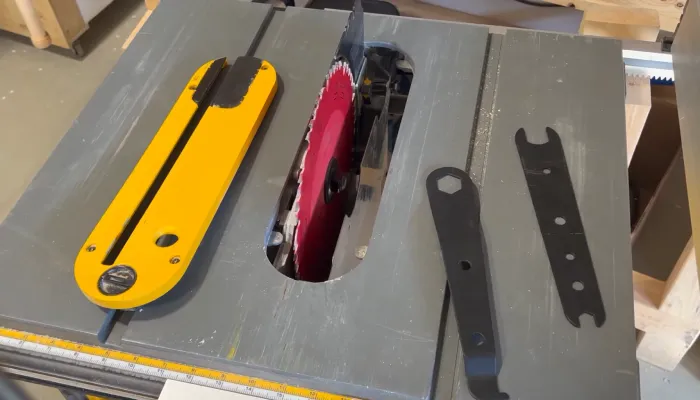

Mechanical Design and Key Components

The worm gear mechanism is pretty essential, isn’t it? It really does a fantastic job of converting the motor’s rotation into high torque, thanks to its threaded design. This design allows for high gear reduction ratios, often achieving 50:1 or 100:1, making it ideal for torque multiplication.

Plus, the armature shaft, which is supported by multiple bearings, helps ensure that everything rotates smoothly and stably even when under load.

Now, let’s talk about alignment and bearing retention. It’s super important to have them properly aligned and securely held in place. This not only maintains consistent performance but also helps in reducing wear over time.

Worm Gear Mechanism

When you examine the worm gear mechanism, you’ll find it consists of two main components: a worm, which looks like a screw, and a worm wheel, a toothed gear set at a 90-degree angle to the worm’s shaft. This setup enables high reduction ratios in a compact form, perfect for high torque and precise motion control.

The worm typically drives the worm wheel, and its self-locking nature prevents reverse motion, enhancing safety.

| Component | Details |

|---|---|

| Worm | Threaded shaft, hardened steel |

| Worm Wheel | Toothed gear, bronze or cast iron |

| Gear Ratio | Depends on worm starts and teeth |

This mechanism ensures smooth, reliable operation in worm drive saws and similar machinery. Left-handed users often prefer saws with adjustable bevels in their design to enhance flexibility and control during cutting tasks.

Shaft and Bearings

How does the shaft and bearing assembly guarantee efficient power transfer and durability in a worm drive saw?

The shaft, usually alloy steel treated for strength, transfers motor torque directly to the worm gear and saw blade.

Bearings, often tapered roller types, support the shaft by handling radial and axial loads, maintaining precise alignment under stress.

Proper bearing placement minimizes shaft protrusion, improving handling and structural rigidity.

Precision-machined bearing seats and adjustable shims ensure tight fits and ideal preload, reducing vibration and wear.

The shaft’s diameter and keyways are engineered to withstand peak torque and bending forces from blade mounting and cutting.

Seals keep lubrication in and contaminants out, extending service life. Optimized lubrication with SEW GearOil Poly enhances heat dissipation and reduces friction, contributing to longer component life and improved efficiency.

Additionally, selecting components with proper horsepower ratings is essential to ensure the assembly can withstand the demands of more powerful motors without premature failure.

Together, these design elements ensure smooth power flow, durability, and compatibility with accessories, enhancing saw performance and operator comfort.

Advantages of Worm Drive Saws Over Other Types

Although worm drive saws may weigh more than sidewinders, their greater power and torque give you a clear advantage when cutting through dense or thick materials. The worm gear design multiplies motor torque, letting you make smoother, forceful cuts with less chance of binding or stalling.

You’ll also appreciate their durability; enclosed gears and metal housings protect critical parts from dust and wear, extending the saw’s lifespan and reducing maintenance. This design helps the motor run cooler and more efficiently, so you can work longer without overheating, which is crucial to prevent motor overheating.

Plus, the stable weight distribution increases cutting precision. The blade’s position on the left side also improves visibility and accuracy for right-handed users.

Professionals prefer worm drives for heavy-duty tasks and tough environments because they deliver reliable performance, efficiency, and longevity that other saw types often can’t match.

Blade Orientation and Ergonomic Benefits

Beyond their power and durability, worm drive saws offer distinct advantages in blade orientation and ergonomics that impact your control and cutting accuracy.

The blade sits on the left side, with the motor at the rear, giving you a longer, narrower saw body that improves visibility of the cut line if you’re right-handed. This layout lets you naturally align your sight with the cut, especially during straight rips. Additionally, the miter and bevel angles available on some saws can enhance versatility in complex cuts.

The rear motor also reduces interference between your body and the saw, enhancing maneuverability in tight spaces. Their high torque allows for sustained cutting power, even under heavy-duty demands.

Ergonomically, the balanced weight distribution and elongated chassis reduce fatigue, letting you maintain better control over long cuts.

Two-handed operation becomes more comfortable, allowing you to stabilize the saw for precise bevels and plunge cuts.

Common Applications and Professional Use Cases

When you need a saw that combines power with precision, worm drive saws stand out across various professional applications.

You’ll find them ideal for heavy-duty framing, cutting large dimensional lumber like beams and headers with high torque and consistent power. Their ability to maintain proper blade tension helps ensure smooth cuts and reduces the risk of blade breakage on tough materials.

Roofing contractors rely on them for sheathing tasks, handling plywood and OSB efficiently while reducing fatigue during overhead cuts.

If you often rip long boards or make plunge cuts, these saws deliver accuracy and strength without overheating. Their high torque and fast cutting speeds make them especially efficient for these demanding jobs.

Professionals appreciate their durability on demanding job sites, where reliability and minimal maintenance matter.

Plus, you can use different blade sizes to suit various materials, from engineered lumber to hardwood sheathing.

Whether framing, roofing, or heavy ripping, worm drive saws meet your toughest cutting needs.

Comparison Between Worm Drive and Sidewinder Saws

How do worm drive saws compare to sidewinder saws in everyday use?

You’ll find worm drives offer more torque and better cut line visibility thanks to their left-mounted blade and rear motor, making them ideal for heavy-duty tasks. Their design often results in a heavier tool, which can contribute to better stability during tough cuts but may require more effort to handle.

Sidewinders, with their lighter weight and faster blade speed, excel in quick, clean cuts and easier handling. The balance and motor placement make them more suitable for tasks requiring agility and speed.

Consider these key differences:

Key differences include power, speed, weight, balance, and maintenance requirements.

Power and speed: Worm drives deliver higher torque but slower blade speed; sidewinders have faster blade speed with less torque. This difference is due to the motor placement, which directly influences torque and blade speed.

Weight and balance: Worm drives are heavier, providing stability but causing fatigue; sidewinders are lighter and more maneuverable.

Maintenance: Worm drives require regular lubrication; sidewinders have sealed, maintenance-free gearboxes.

Choosing depends on your cutting needs and how much effort you want to expend. For heavy-duty applications, a motor with at least 1.5 HP is generally recommended to ensure optimal performance.

Frequently Asked Questions

How Do I Maintain a Worm Drive Saw for Optimal Performance?

You want your worm drive saw running smoothly, not overheating or jamming.

Keep oil levels just at the bottom threads. Too little and it suffers, too much and it leaks.

Change oil yearly, or sooner if dirty. Warm the saw before draining to loosen grime.

Clean vents and lubricate tilt mechanisms regularly.

Sharpen or replace blades promptly and check electrical parts for damage.

This routine keeps your saw precise and dependable every time.

What Safety Gear Is Recommended When Using a Worm Drive Saw?

You should wear safety goggles to protect your eyes from debris and wood chips.

Plus, use hearing protection like earmuffs or earplugs because the saw is loud.

Use leather or nitrile gloves to guard your hands against cuts and vibrations.

Steel-toed boots will shield your feet from heavy objects or accidental blade contact.

If dust is present, wear a respirator or dust mask to avoid inhaling harmful particles.

Can Worm Drive Saw Blades Be Replaced With Standard Circular Saw Blades?

You shouldn’t replace worm drive saw blades with standard circular saw blades.

They often have different arbor sizes and mounting systems, which can cause improper fit, vibration, and unsafe operation.

Using blades not designed for worm drive saws risks damaging the gear train and reduces cutting performance.

Always choose blades specifically made for your worm drive saw to guarantee safety, maximum torque, and clean cuts.

Don’t compromise on compatibility or quality.

How Loud Is a Worm Drive Saw Compared to Other Saw Types?

You’ll find worm drive saws produce noise up to about 105 dBA, louder than many belt-driven saws like table saws (90-95 dBA).

But they are generally quieter than some universal motor circular saws, which hit 108-113 dBA.

Miter saws often top 113 dBA, so they’re louder than worm drives.

Since 105 dBA is quite loud, you’ll definitely need hearing protection and should limit exposure time to protect your hearing on the job.

Are Worm Drive Saws Suitable for DIY Home Projects?

You wouldn’t use a horse-drawn carriage for a quick trip.

Similarly, worm drive saws are ideal if you’re tackling heavy-duty DIY projects like framing or cutting thick lumber.

They offer high torque and durability but can tire you out due to their weight and size.

For light, occasional tasks, you’d be better off with a lighter, direct drive saw that’s easier to handle and store.

Choose the Right Worm Drive Saw for Your Next Project

If you want a saw that feels like it’s powered by a tiny tank under your control, the worm drive saw is your go-to.

Its torque and durability make cutting through tough materials almost effortless, turning you into a precision powerhouse on any job site.

Forget struggling with less reliable tools. This saw’s design puts power, control, and ergonomic comfort right in your hands, so you can tackle any project like a pro every single time.