How to Slow Down a Band Saw: 4 Effective Methods

Band saws are an essential tool in many workshops, providing efficient and accurate cutting for various materials. However, sometimes, the speed at which they cut may be too fast for certain materials or cutting tasks.

In such situations, it’s necessary to slow down a band saw to achieve optimal results. According to my research, I have found various effective approaches to slowing down the cutting speed of a band saw.

One thing that caught my attention is using gearboxes or pulleys, which allows for mechanical speed reduction with a reduction ratio of 15:1 to 20:1, making it an ideal option for metal-cutting tasks. Another option I have encountered is speed reduction with a speed reducer.

I will discuss all the methods I found during my research so that you can select the best option based on your specific requirements.

How to Slow Down a Band Saw: 4 Methods to Apply

In my exploration of slowing down a band saw, I’ve explored four distinct methods to help you do it.

- Considering mechanical speed reduction

- Speed reduction with a speed reducer

- Creative modification with additional motor

- Using extra shafts and pulleys

1. Considering Mechanical Speed Reduction

I have found that some members of the wood and metal worker community suggest mechanical solutions as a reliable means of slowing down a band saw.

You can consider utilizing mechanical speed reduction through gearboxes or pulleys to achieve a slower speed on your band saw. This method is recommended for reducing the range of 15:1 to 20:1, which is essential for effective metal cutting.

Start by assessing your band saw’s specifications, including motor horsepower and current speed. Research and gather suitable gearboxes or pulley systems based on the desired speed reduction ratio and torque requirements. Calculate the speed reduction ratio based on the speed difference between wood and metal cutting.

Purchase high-quality gearboxes or pulleys that are compatible with your band saw’s motor. Disconnect the saw from the electrical source and clear the workspace to prepare it for modification. If applicable, carefully remove any existing pulleys or gear systems.

Follow the manufacturer’s instructions to install the new gearbox or pulley system, ensuring proper alignment and attachment. Adjust the belt tension according to manufacturer recommendations if applicable.

Test the machine to ensure smooth operation and make any necessary fine-tuning adjustments to achieve the desired metal-cutting speed.

2. Speed Reduction With a Speed Reducer

Another excellent method that grabbed my attention is slowing down a band saw by incorporating a speed reducer. When considering a speed reducer, evaluate your band saw and motor specifications to ensure compatibility.

Research and identify suitable speed reducer options based on factors such as reduction ratio, torque capacity, and type of speed reducer. Calculate the required reduction ratio by determining the difference between wood and metal cutting speeds.

Make sure you purchase a high-quality speed reducer that meets your calculated requirements. Before modification, power off and disconnect the band saw.

Locate the motor and band saw shafts involved in the speed reduction. Follow the manufacturer’s instructions to install the speed reducer, ensuring proper alignment and orientation.

If applicable, adjust belt tension according to the manufacturer’s recommendations. Perform a test run to check for smooth operation. Fine-tune the reduction ratio if necessary. Reassemble and secure all components.

It is imperative to emphasize that safety should be paramount whether you are operating a band saw or a table saw. Implementing safety measures and adhering to recommended practices contribute significantly to a secure and effective working environment, ensuring the well-being of the operator and those in the vicinity.

3. Creative Modification With Additional Motor

In a creative modification, I discovered some woodworkers and metalworkers reduce band saw speeds for cutting aluminum by adding an extra motor.

To proceed with this creative modification, ensure that the selected additional motor is compatible with your band saw in terms of horsepower, voltage, and speed ratings.

Conduct thorough research to find a suitable motor that complements your existing motor and can be easily synchronized with the band saw. Based on the speed difference between wood and metal cutting, determine the specifications for the additional motor based on the required speed reduction.

Pay meticulous attention to the quality of components such as belts and pulleys to ensure the longevity of your bandsaw blade. Securely mount the additional motor in a suitable location and align it properly with the band saw’s drive system.

Connect the motors using a pulley system and install a switching mechanism for control. Perform a test run and fine-tune the motor operation if necessary.

4. Using Extra Shafts and Pulleys

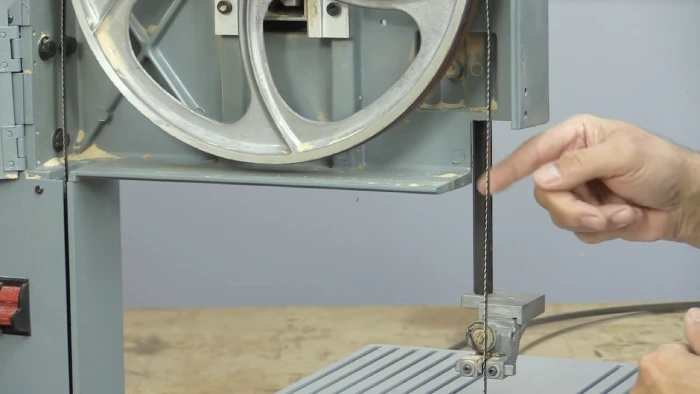

I found installing an extra shaft with new pulleys quite appealing for someone seeking a straightforward approach. This method involves connecting the motor to a large pulley on the new shaft, with another small pulley on the new shaft linked to the existing large pulley on the bandsaw.

The key is to calculate the pulley ratios accurately to achieve the desired blade speed for metal cutting. It’s crucial to refer to the specific model’s instructions and consult online resources for a successful conversion.

To begin, evaluate your band saw’s compatibility, research and gather the necessary components, and calculate the speed reduction ratio. Once you have all the information, purchase the components and prepare the band saw for modification.

Next, locate suitable mounting points and securely install the extra shaft. Install pulleys on both the band saw and the extra shaft, and connect the pulleys with belts.

After installing, perform a test run to ensure everything functions properly. Fine-tune pulley sizes and belt tension if needed to achieve the desired blade speed.

Can you utilize a Variable Frequency Drive (VFD) to reduce the speed of your band saw?

While the idea of using a VFD to slow down your band saw might seem attractive, it’s not recommended due to several limitations. VFDs can result in motor stalling, overheating, and insufficient torque when you’re attempting to reduce the speed of a wood band saw for metal cutting occasionally.

Experts suggest relying on mechanical speed reduction, including gears, pulleys, and belts. Such speed reduction methods guarantee optimal results when cutting metal and wood without compromising band saw performance.

Therefore, it’s advisable to avoid using a VFD for such purposes and opt for mechanical speed reduction means.

What speed is recommended for cutting metal with a band saw?

To achieve precise and efficient metal cuts, operating a band saw at a speed range of 100 to 300 feet per minute (fpm) is recommended. This speed range is optimal for cutting metal materials, ensuring accuracy and maintaining the longevity of the blade.

Operating at a slower speed reduces the risk of overheating and prolongs the blade’s life, as it prevents excessive friction and wear. Additionally, cutting metal slower allows for better control and accuracy, resulting in clean and smooth cuts.

It is crucial to adjust the band saw to the specified speed range when working with metal to ensure the safety, performance, and quality of the cutting process.

Also, maintaining the recommended speed range helps prevent potential issues such as bandsaw blade twists, which may occur when the saw blade binds in the cut.

Mindfully Modify Your Band Saw to Slow Down

When you need to tailor your band saw for optimal cutting performance, choose any of the four methods I have explored. Each method has its advantages, whether you use gearboxes, pulleys, speed reducers, an additional motor, or extra shafts and pulleys to slow down your band saw.

Remember, while a Variable Frequency Drive (VFD) may seem tempting, it’s advisable to steer clear due to potential issues. Embrace these proven methods to ensure precision and efficiency in your band saw’s metal-cutting endeavors. Embark on a customized cutting experience with the band saw.