How to Keep Scroll Saw Blades From Breaking: 7 DIY Solutions

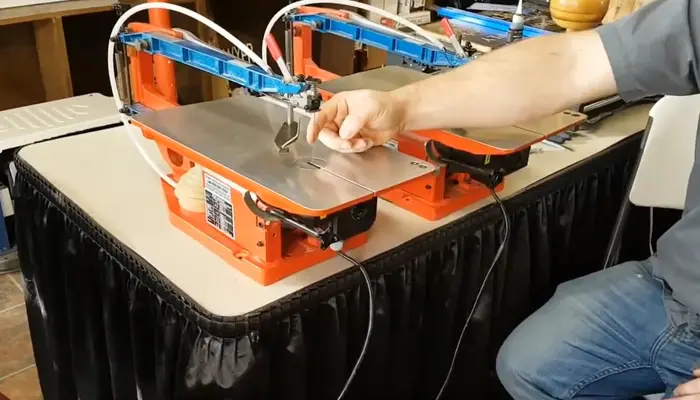

Scroll saw blades play an essential role in woodworking projects, but they can be problematic when they break in the middle of a project. As a woodworking enthusiast, I’ve researched how to stop scroll saw blades from breaking. Through my research, I have found several effective strategies for this issue.

Adjusting the blade tension carefully before beginning any project can ensure it’s not too loose or too tight. This can significantly reduce the chances of blades breaking. Another crucial aspect is avoiding excessive force. When cutting through dense materials, pushing too hard on the blade can be detrimental.

As part of this article, I will share my findings with you, along with some solutions that can help you avoid blade breakage and increase your productivity. So keep reading for detailed info.

How to Keep Scroll Saw Blades from Breaking: Effective Solutions

To keep scroll saw blades from breaking, I’ve found several solutions, such as:

- Maintain proper blade tension

- Avoid excessive force

- Choose the appropriate blade

- Maintain quality blades

- Proper blade alignment

- Replace dull blades immediately

- Prevent overheating and corrosion

1. Maintain Proper Blade Tension

Maintaining proper blade tension is crucial for preventing scroll saw blades from breaking. If the tension is too loose, the blade will wander and may snap. However, if the tension is too tight, the blade can become overstressed and break prematurely.

A well-tensioned blade should have minimal side-to-side movement. Regularly checking and adjusting the blade tension throughout your project will help ensure smooth and successful cutting without any breakages.

2. Avoid Excessive Force

Using too much pressure while cutting is a common mistake that can cause scroll saw blades to break. Keep in mind that scroll saw blades are designed to cut through materials efficiently with the right amount of pressure.

Applying excessive force not only puts unnecessary strain on the blade but it can also cause the teeth to bend or snap. To avoid this, I recommend using a light and steady hand when cutting. Let the blade do the work, and you’ll have smoother cuts without the risk of breaking the blade.

3. Choose the Appropriate Blade

When selecting a scroll saw blade, choose the appropriate type and size for the specific material and thickness. This ensures that the blade can effectively cut through the material without breaking.

For softer woods, a blade with fewer teeth per inch (TPI) is recommended, as it will quickly remove material. Conversely, harder woods require a blade with more TPI to achieve clean and precise cuts.

The thickness of the material also plays a role in blade selection. Thicker materials require blades with more TPI to prevent binding and breakage. Consider the width of the blade, as narrower blades are more suitable for intricate and detailed cuts.

4. Maintain Quality Blades

To maintain quality blades and prevent them from breaking, it’s essential to regularly clean and lubricate them.

After each use, I recommend cleaning the blades thoroughly to remove any debris or sawdust that may have accumulated. This can be done by using a small brush or compressed air to clean between the teeth of the blade gently.

Also, applying a lubricant, such as silicone spray or blade wax, will help reduce friction and prolong the blade’s life. It’s important to apply the lubricant sparingly and evenly to ensure smooth and efficient cutting.

5. Proper Blade Alignment

Proper blade alignment is crucial for smooth and accurate cutting, as well as for the longevity of the blade. To ensure proper blade alignment and prevent scroll saw blades from bending or breaking, ensure they’re securely held in the blade holder clamps while maintaining correct alignment.

Before securing the blade in the clamps, double-check that it’s centered and positioned straight. Note that the blade shouldn’t be too tight or loose in the clamps, as both scenarios can lead to breakage. I recommend adjusting the tension so that the blade is held firmly but still allows for some flexibility.

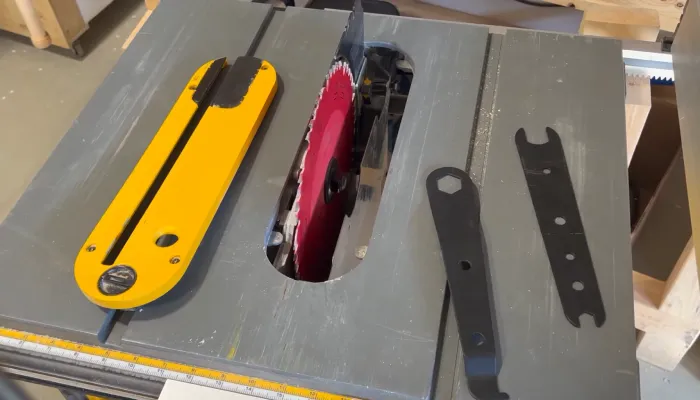

6. Replace Dull Blades Immediately

In my professional opinion, replacing dull blades promptly is essential in preventing breakage and ensuring the longevity of scroll saw blades. Always unplug the scroll saw before changing blades. Make sure the new blade is securely in place before reconnecting the saw.

When a blade becomes dull, it requires more force to cut through the material, which increases the likelihood of the blade breaking. Also, the increased pressure and friction generated by a dull blade can lead to excessive heat, further compromising the blade’s integrity.

To avoid these issues, regularly inspect the blades and replace them as soon as signs of dullness appear. Maintaining a supply of sharp blades on hand will minimize downtime and allow smooth, efficient cutting.

7. Prevent Overheating and Corrosion

To prevent overheating and corrosion, I recommend regularly lubricating scroll saw blades with a suitable oil or lubricant. This helps reduce friction and heat buildup during cutting, keeping the blades cool and preventing them from breaking.

When applying the lubricant, follow the manufacturer’s instructions and use a small amount to avoid any excess that could interfere with the cutting process.

Additionally, keep your tools and blades properly maintained to prevent rust and corrosion. After each use, wipe down the blades with a clean cloth to remove any moisture or debris that could lead to corrosion. You can also use a guard or shield to protect the blade from rusting.

Storing the blades in a dry area and using a rust inhibitor can also help prolong their lifespan and prevent breakage caused by corrosion.

How to keep scroll saw blades tensioned properly to avoid Breaking?

To avoid breaking scroll saw blades, keep them properly tensioned. There are several key points to consider.

1. Use a High-Pitched Sound as a Guide

When properly tensioning scroll saw blades to avoid breaking, I find it helpful to listen for a high-pitched sound as a guide. When you pluck the blade gently like a guitar string, a properly tensioned blade will produce a clear, high-pitched sound. This indicates that the blade is properly tensioned and ready for use.

If the sound is too low or the blade feels floppy, the blade is too loose and needs to be tightened. By using this method, you can ensure that your scroll saw blades are properly tensioned, reducing the risk of them breaking during use.

2. Minimize Side-to-Side Movement

Proper tensioning is crucial for smooth and accurate cuts, as well as for preventing the blade from snapping. To minimize the side-to-side movement of the scroll saw blade and avoid breaking while using the saw, I recommend that you adjust the tension of the blade.

3. Regularly Check and Adjust Tension

A key step in preventing scroll saw blade breakage is regularly checking and adjusting the tension to ensure proper tensioning. Tension can change over time, especially during long scrolling sessions or when changing blades.

To maintain the correct tension, start by turning off the scroll saw and unplugging it for safety. Then, use the tension adjustment knob or lever, usually located on the top or side of the saw, to increase or decrease the tension as needed.

4. Avoid Over-Tightening

To avoid breaking scroll saw blades, maintain proper tension and avoid over-tightening. While it may be tempting to tighten the blade as much as possible, this can cause more harm than good. Over-tightening puts excessive stress on the blade, making it more prone to breakage.

Instead, find the right balance when tensioning the blade. Adjust the tension until you hear a clear and consistent hum when the saw is running. You should be able to pluck the blade and hear a sharp and clear sound.

If it feels too loose, tighten it until you achieve the desired tension. Remember, it’s better to have a slightly looser blade than one over-tightened and at risk of breaking.

Does Scroll Saw Blade Thickness Matter to avoid breaking?

When choosing scroll saw blades, the thickness is crucial in preventing breakage and ensuring optimal cutting results. The thickness of the blade determines its strength and stability during the cutting process.

Thicker blades are generally more durable and less prone to breaking, making them suitable for cutting denser materials or making long, straight cuts. Conversely, thinner blades are more flexible and are better suited for intricate and detailed cuts. Match the blade thickness to the material you’re working with and the type of wood cuts.

How long should scrolls saw blades actually last?

Scroll saw blades typically have a lifespan of 15-45 minutes of continuous use, depending on various factors such as wood type, operating speed, and tension issues.

Thicker or hardwoods tend to wear down blades faster compared to softer woods. Additionally, higher operating speeds can put more stress on the blade, reducing its longevity.

Tension issues, whether the blade is too tight or too loose, can also contribute to a shorter blade lifespan. Keep these factors in mind when using a scroll saw to ensure that the blade lasts as long as possible.

Mastering Scroll Sawing: The Secrets to Success & Longevity

When scroll sawing, the key to success is properly tensioning blades and choosing the right saw blade thickness.

Through my research, I have found that maintaining blade tension, avoiding excessive force, and choosing appropriate blades are all critical aspects that contribute to Scroll Saw blade longevity. If you follow these guidelines, you can prevent scroll saw blade breakage and increase productivity.

Also, remember investing in high-quality blades made from hardened steel and maintaining them properly is essential for the most effective results. So keep these suggestions in mind, stay patient, and practice to become a scroll sawing master.