How Tall Should a Table Saw Be: 5 Factors [Important]

Selecting the optimal height for your table saw is a critical decision that can significantly impact your woodworking experience. Whether you are a seasoned professional or a hobbyist, having the right table saw height is important in precise woodworking. But how do you determine the right height for your table saw?

To determine the optimal height for your table saw, I recommended considering a formula based on 50% of your overall height or approximately half of your stature. Most standard table saws range from 34 to 38 inches in height, although some cheaper models are as low as 32 inches.

In this discussion, I will explore the factors you must consider when determining the height of a table saw. So, let’s dive in and explore the key aspects of this important topic.

What to Consider When Determining the Table Saw Height?

When determining the height of your table saw, I’ve listed five key factors you should consider.

- Ergonomics and personal comfort

- Your height and leverage

- Integration with other surfaces

- Table saw adjustability

- Adjustability and temporary solutions

1. Ergonomics and Personal Comfort

In my opinion, you must first consider your comfort and ergonomics, ensuring that you can work efficiently without straining your back or compromising your posture. Finding the right height is crucial to prevent fatigue and injury during prolonged use.

A height range of 30 to 40 inches is commonly recommended, with 34 inches often considered a practical choice. However, personal preferences and body proportions may vary, so it’s advisable to experiment and adjust the height to suit your needs.

When setting the table saw height, ensure that your arms are comfortably extended while gripping the workpiece and that your wrists are in a neutral position.

2. Your Height and Leverage

Finding the ideal table saw height for your individual needs is crucial. Having the right upper body leverage is important, allowing your palms to rest on the table comfortably. This consideration becomes especially important when aligning various surfaces in your workshop.

Some professional woodworkers often find a sweet spot around 34 to 38 inches, but making personal adjustments based on height is crucial for optimal efficiency. A general rule of thumb is to aim for a table saw height of around 50% or approximately half your body height.

3. Integration with Other Surfaces

To ensure seamless integration between your table saw and other surfaces in your workshop, consider the height of your table saw concerning workbenches and assembly tables. Achieving a harmonious workflow requires strategic placement and coordination between these surfaces.

Start by evaluating the layout of your workspace and determining the optimal positioning of the table saw. Placing it in a central location with ample space ensures easy access and promotes a logical workflow.

Additionally, consider the height of your workbenches and assembly tables. The table saw should align with these surfaces to facilitate smooth material transfer and minimize strain on your body.

4. Table Saw Adjustability

When determining the height of your table saw, consider various factors contributing to its adjustability and overall functionality.

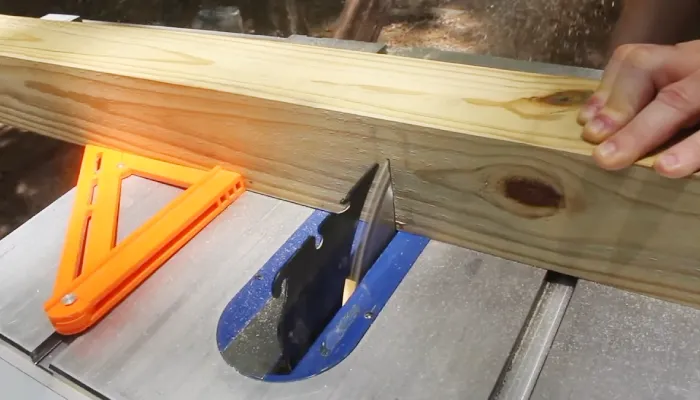

A table saw with adjustable features provides the flexibility needed for different woodworking tasks. Look for a table saw that offers tilt and bevel adjustments, allowing you to make angled cuts for creating beveled edges, mitered joints, and other precision cuts.

Evaluate the adjustability of the fence system as well. A robust and easily adjustable fence is essential for accurate and repeatable cuts. It should lock securely in place and easily adjust for different rip capacities.

Consider these factors when determining the height of your table saw to ensure optimal adjustability and functionality for your woodworking projects.

5. Adjustability and Temporary Solutions

Consider the impact of factors such as mobile stands, leveling feet, and the tool’s weight when determining the height of your table saw for optimal adjustability and functionality in your woodworking projects.

When it comes to adjustability, mobile stands can be a game-changer. They allow you to move the table saw around your workshop, making it convenient to work on different projects.

Additionally, leveling feet are essential for creating a stable and level surface. They can be adjusted to compensate for uneven floors or to achieve the perfect working height.

Furthermore, the weight of the tool itself should be taken into consideration. Heavier table saws may require additional support or a higher working height. Sometimes, temporary platforms provide a quick and easy solution to achieve a comfortable working height.

Can I adjust the height of my table saw?

You can easily adjust the height of your table saw to accommodate your preferences or the task you’re working on. Many table saw models offer height-adjustable features that allow you to customize the height according to your needs.

To determine if your table saw has this capability, check the specifications provided by the manufacturer. Adjusting the height of your table saw may vary depending on the model you have.

Typically, a mechanism or lever will allow you to raise or lower the table. This can be done by turning a handle or using a crank to adjust the height. When adjusting the height of your table saw, ensure the saw blade is parallel to the table surface.

This will help to ensure accurate and precise cuts. You may need to consult the user manual or seek guidance from a professional if you’re unsure about this adjustment.

What impact do mobile stands and leveling feet have on table saw height?

Mobile stands and leveling feet can significantly impact the overall height of a table saw, so you should adjust them accordingly. These features are designed to provide stability and mobility to your table saw but can also affect its height.

Mobile stands, for example, are usually equipped with wheels that make it easy to move around the workshop. However, when fully extended, these wheels can add a few inches to the saw’s height.

Similarly, leveling feet, designed to stabilize the table saw on uneven surfaces, can also affect its height. When the leveling feet are fully extended, they can raise the saw by a few inches.

Are there industry standards for table saw height?

There is no strict industry standard for table saw height, as it can vary based on personal preferences, ergonomic considerations, and the specific tasks performed by woodworkers. Table saw height should be determined by what feels comfortable and allows for safe and efficient operation.

Ideally, the table should be at a height that allows you to comfortably stand upright and maintain a natural posture while operating the saw. This will help reduce the risk of strain or injury during prolonged use.

Additionally, the specific tasks you frequently perform on your table saw may influence the height at which it should be set. For example, if you frequently work with larger or heavier materials, consider setting the table at a height that allows easier material handling and support.

Find Your Perfect Table Saw Height for Maximum Comfort and Safety

Choosing the right height for your table saw ensures optimal comfort and safety during your woodworking projects. You can tailor their table saw setup to enhance efficiency and safety in their workshops by considering ergonomics, the impact of accessories, versatility, and safety.

As there is no one-size-fits-all solution, the key is to experiment, gather insights from the community, and customize the table saw height to suit individual preferences and project requirements. So, don’t underestimate the importance of getting the height just right for a truly exceptional woodworking experience.