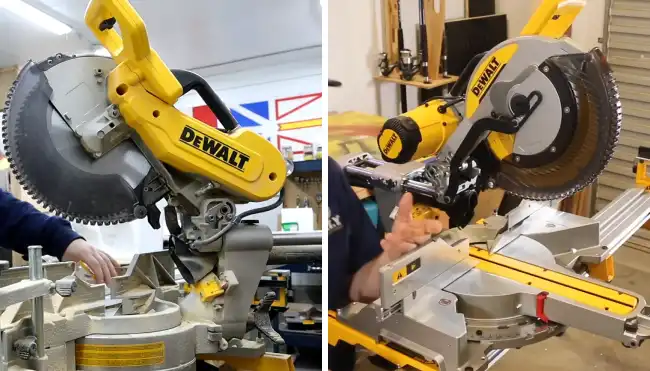

Dewalt Miter Saw 779 vs 780: 5 Differentiating Factors

Dewalt miter saw 779 and 780 models present a choice that reflects your specific woodworking needs. As you compare these two models, you’ll discover key differences that can greatly impact your cutting precision and overall project efficiency.

One key difference lies in the cutting system and alignment. The DWS780 incorporates an XPS with LED lights, casting a precise shadow of the blade onto the workpiece for accuracy without a laser guide.

In contrast, the DWS779 uses a traditional laser guide, potentially less visible in well-lit conditions than the DWS780’s LED shadow.

Regarding weight and portability, the DWS780’s lighter build and convenient carry handle make transporting it to various job sites easier. On the other hand, the DWS779 is slightly less portable due to its higher weight.

Other differences are also available that should be known before selecting a miter saw model. We will discuss all the differences between the Dewalt miter saw 779 vs. 780 so that you can choose the most appropriate for your needs.

Dewalt Miter Saw 779 vs 780: Key Differences

When comparing the Dewalt Miter Saw 779 and 780, several key differences exist. They are categorized as follows:

- Cutting system and alignment

- Weight and portability

- Vertical cutting capacity

- Price and budget

- Dust collection and efficiency

Let’s examine the differences between the 779 and 780 models of the Dewalt miter saw.

1. Cutting System and Alignment

In terms of cutting system and alignment, the DWS780 takes the lead. The DWS780’s advanced XPS system with LED lights provides a precise cutline.

The XPS system on the DWS780 is a standout feature, as it casts a shadow of the blade onto the workpiece, creating a highly accurate cutline without needing a laser guide. This eliminates the hassle of calibration and ensures precise cutting every time.

On the other hand, the DWS779 relies on a traditional laser guide system. The DWS779’s laser guide system is effective but may have reduced visibility in well-lit conditions compared to the shadow cast by the LED lights on the DWS780.

While both systems can help with cutting alignment, the XPS system on the DWS780 offers superior accuracy and ease of use.

2. Weight and Portability

The DWS780 is distinguished by its lighter weight and convenient carry handle, enhancing its portability. Weighing around 56 pounds, it is significantly lighter than its counterpart, the DWS779, which weighs around 70.3 pounds.

This weight difference makes a noticeable impact when transporting the miter saw between job sites or different locations. The DWS780’s reduced weight allows for easier lifting and maneuvering, minimizing strain on your body during transportation.

The convenient carry handle adds to its portability, providing a comfortable grip and making it effortless to carry the saw from one place to another.

Whether you’re a professional contractor or a DIY enthusiast, the DWS780’s lighter weight and carry handle make it a practical choice for those prioritizing portability and ease of transportation.

3. Vertical Cutting Capacity

With its extended vertical cutting capacity, the DWS780 handles larger workpieces perfectly. The belt-driven motor and gearbox design of the DWS780 allows it to make precise and smooth vertical cuts, making it an ideal choice for professional carpenters and DIY enthusiasts alike.

This feature enables you to work with larger pieces of wood or other materials, giving you the flexibility to tackle a wider range of projects.

The DWS779, on the other hand, may have slightly limited vertical cutting capacity due to differences in internal design. This means that if you often work with larger workpieces, the DWS780 would be a better option for you.

Its extended vertical cutting capacity ensures that you can make accurate cuts on even the tallest pieces of material, providing you with the versatility you need for your projects.

4. Price and Budget

If you’re on a tighter budget, the DWS779 might be your better choice. Priced more affordably than the DWS780, this miter saw provides a cost-effective option without compromising on quality.

With the DWS779, you can still enjoy the reliability and durability that Dewalt products are known for. It offers precise and accurate cuts, making it suitable for a variety of woodworking projects.

While the DWS779 may not have all the additional features of the DWS780, it still delivers exceptional performance at a more budget-friendly price point. This makes it an attractive option for DIY enthusiasts or professionals who don’t require the advanced capabilities provided by the DWS780.

5. Dust Collection and Efficiency

The DWS780’s optimized dust chute and port design give it a slight edge in efficient dust collection compared to the DWS779. While both models offer effective dust collection systems, the DWS780’s design might provide slightly better dust extraction.

The optimized dust chute and port on the DWS780 are specifically designed to enhance the collection and removal of dust particles, ensuring a cleaner and safer working environment. This design feature helps to minimize dust buildup and clogging, allowing for uninterrupted cutting and improved overall efficiency.

Dewalt Miter Saw DWS779 and DWS780 Comparison Table

| Aspect | DWS779 | DWS780 |

| Cutting System & Alignment | Traditional Laser Guide System | Advanced XPS System with LED Lights |

| Weight & Portability | Heavier (70.3 lbs) | Lighter (56 lbs) with Carry Handle |

| Vertical Cutting Capacity | Limited by Design | Extended Vertical Cutting Capacity |

| Price & Budget | Budget-Friendly | Higher Priced with Added Features |

| Dust Collection Efficiency | Effective | Optimized Dust Chute & Port Design |

Which Dewalt miter saw should you choose, the 779 or the 780?

You should consider your specific needs and priorities when deciding between the Dewalt miter saws, the DWS779, or the DWS780.

If you prioritize advanced features and precision and are willing to invest in a higher-end tool, the DWS780 would be your preferred choice. Its XPS (Crosscut Positioning System) with built-in LED lights offers superior accuracy without the need for calibration, making it an exceptional choice for achieving precise cuts.

On the other hand, if you’re mindful of your budget and can work with slightly fewer features, the DWS779 remains a reliable and budget-friendly option. It offers accurate cuts with its traditional laser guide system and can even be upgraded with an XPS LED light system if you desire comparable precision.

Ultimately, your choice between the DWS779 and the DWS780 depends on your preferences, project requirements, and budget considerations.

How to Maintain Dewalt Miter Saw Models DWS779 and DWS780?

To properly maintain your Dewalt Miter Saw models DWS779 and DWS780, there are several key points you need to keep in mind.

1. Cleaning and Removing Dust Particles

Regular cleaning is essential to keep your DeWalt Miter Saw models DWS779 and DWS780 in optimal condition. Start by using compressed air to remove dust particles from your DeWalt Miter Saw models DWS779 and DWS780.

Be careful not to damage any sensitive components. Dust accumulation can hinder the performance of your saw, so it is crucial to clean it regularly.

Begin by disconnecting the saw from the power source and removing any sawdust bags or collection systems. Using a can of compressed air, direct the nozzle toward the dust-covered areas. Pay special attention to the blade guard, motor housing, and air vents.

Ensure that all the dust particles are blown away from the saw. Be cautious not to blow the dust into any other electrical components.

Once the dust has been removed, inspect the saw for any remaining debris. Gently brush it away using a soft-bristled brush. Regular cleaning will help maintain the efficiency and longevity of your DeWalt Miter Saw.

2. Lubricating Moving Parts

Regularly applying the recommended lubricant to the moving parts of your DeWalt miter saws helps minimize friction and wear. This ensures the smooth operation of your saws and prolongs their lifespan.

To lubricate the moving parts, start by turning off the saw and ensuring the blade is stationary. Use compressed air to remove dust and debris from the components. After cleaning, wipe the parts with a cloth to ensure no residue is left.

Next, apply an appropriate lubricant to the identified components, such as the pivot points and sliding rails. It is important to follow the manufacturer’s recommendations for the type of lubricant to use. Once applied, operate the saw a few times to distribute the lubricant evenly.

3. Inspecting and Replacing Worn-Out Parts

Check your DeWalt miter saws’ kerf board, power cord, and brushes for any signs of wear or damage, and take prompt action to replace or repair affected parts.

The kerf board, which guides the blade and prevents kickback, should be inspected regularly for chipping or cracks. Any damage to the kerf board compromises the safety and accuracy of your cuts.

Additionally, examine the power cord for any fraying or exposed wires. Damaged cords can pose electrical hazards and should be replaced immediately.

Lastly, inspect the brushes, which provide power to the motor, for any signs of wear or breakage. If the brushes are worn down, they need to be replaced to ensure optimal performance.

4. Sharpening the Blades

When your blades on the DeWalt miter saw DWS779 and DWS780 become dull, consider sharpening them using appropriate tools.

To start the sharpening process, safely remove the blade from the miter saw by loosening the arbor nut and removing any washers. Inspect the blade for chips, dull spots, or damaged teeth. If there is significant damage, replace the blade.

Use specialized tools like a blade sharpener, diamond blade file, or sharpening stone designed for saw blades. Maintain the original angle of each tooth and work on them individually with consistent filing or grinding motions. To prevent overheating, periodically dip the blade in water.

After sharpening, ensure the blade’s balance and securely reattach it to the miter saw following the manufacturer’s instructions.

5. Sticking to Factory Instructions

To ensure optimal performance and avoid any potential risks, it’s crucial to always adhere to the manufacturer’s instructions and precautions for maintaining your DeWalt miter saw models DWS779 and DWS780.

These instructions provide essential guidance on how to care for your tool and ensure its longevity properly.

You should follow the manufacturer’s recommendations for specific maintenance tasks. It could be a cleaning, lubrication, and wear inspection.

Always prioritize the manufacturer’s guidance to maximize the potential of your DeWalt miter saw models DWS779 and DWS780.

Can you upgrade the DWS779 with an XPS LED light system?

To achieve enhanced cutting accuracy on your DWS779 miter saw, you can upgrade it with an XPS LED light system.

This upgrade allows you to enjoy the same precision and cutting alignment as the DWS780 model, which has a built-in XPS system.

The XPS LED light system projects the blade’s shadow onto the workpiece, providing a clear and visible guide for accurate cuts.

By retrofitting your DWS779 with this upgrade, you can ensure that your cuts are precise and aligned with utmost accuracy.

This is especially beneficial when working on intricate projects or when precision is paramount. With the XPS LED light system, you can take your cutting experience to the next level and achieve professional-grade results.

Does the DeWalt DWS779 come with a blade, or do you have to buy one separately?

You don’t need to buy a separate blade for the DeWalt DWS779 miter saw because it comes with a 12-inch, carbide-tipped 32-tooth blade already installed.

This blade is designed to provide precise and clean cuts, making it suitable for various cutting tasks. The carbide-tipped teeth ensure durability and long-lasting performance, allowing you to use the blade for an extended period without frequent replacements.

The 32-tooth configuration balances speed and smoothness, making it suitable for rough and fine cuts. You can easily replace the blade with the included blade wrench if needed.

A pre-installed blade in the DeWalt DWS779 miter saw package saves you the hassle and expense of purchasing a separate blade, making it a convenient and cost-effective choice for your cutting needs.

How deep will a Dewalt DWS780 cut?

The depth of cut you can achieve with the Dewalt DWS780 miter saw is up to 4.4 inches when set at the 0° bevel angle. This means that you can confidently tackle materials with a thickness of up to 4.4 inches without any difficulty.

The DWS780 is designed to handle a wide range of cutting tasks, and its impressive cutting capacity allows you to work with thicker boards and materials.

This depth of cut is especially useful when working with larger pieces of wood or when you need to make deep cuts for specific projects.

Whether you’re working on trim, molding, or any other woodworking task, the Dewalt DWS780’s ability to cut up to 4.4 inches deep provides you with the versatility and precision you need.

Decide on the Best Miter Saw for Your Woodworking Success

When you’re deciding between the Dewalt Miter Saw models DWS779 and DWS780, keep these differences in mind. Your choice depends on your specific woodworking needs and priorities.

Consider factors like cutting accuracy, portability, miter adjustments, vertical cutting capacity, budget, and dust collection efficiency.

Whether you opt for the advanced features of the DWS780 or the cost-effectiveness of the DWS779, each model brings its own advantages to the table.

With this comprehensive understanding, you can select the miter saw that aligns perfectly with your projects and preferences, ensuring precise cuts and efficient woodworking every time.