Delta vs Dewalt Table Saw: 9 Key Differences [Must- Know]

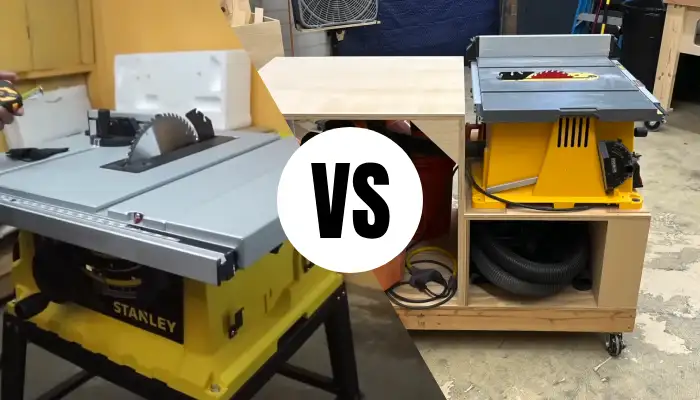

When selecting the right table saw for your woodworking needs, two prominent brands stand out in the market: Delta and DeWalt. Both reputable brands offer a range of table saws catering to various user preferences and requirements. However, there are some significant differences between them.

Delta table saws are larger and heavier than DeWalt saws, making them less portable. These Delta saws often have higher horsepower ratings, providing more cutting power for heavier materials.

However, DeWalt saws have a compact design and are more suitable for limited space or those who need to transport the saw frequently. I’ll explore the major differences between Delta and DeWalt table saws in this comprehensive guide. So, let’s explore the differences.

- Compact Design for Easy Transport

- Rack & Pinion Fence Adjustments

- 24.5″ Rip Capacity for Large Jobs

- Site-Pro Modular Guarding System

- Power-Loss Reset for Safety

- Powerful 15 Amp Contractor Grade Motor

- Massive 32.5 Inch Rip Capacity

- Quick and Accurate Rack-and-Pinion Fence

- Durable One-Piece Rail System

- Portable with Folding Stand

Differences Between Delta and Dewalt Table Saw

When comparing the dimensions and weight of Delta and Dewalt table saws, I find the following differences:

- Dimensions and weight

- Motor power

- Blade controls

- Cutting capacity

- Saw portability

- Blade fences

- Noise levels

- Additional features

- Price range

1. Dimensions and Weight

Delta table saws are generally larger and heavier compared to their DeWalt counterparts. DeWalt’s compact design measures around 48-49 inches in length and weighs approximately 90 pounds.

In contrast, Delta saws boast a robust build, extending to just under 62.5 inches and weighing around 200 pounds. This dimension disparity directly impacts the available table space, making it crucial to consider your workspace limitations and portability requirements.

DeWalt’s smaller size and lighter weight make it more suitable if you’re short on space or must transport it a lot. Delta’s larger size and heavier weight may benefit if you prioritize stability and durability in table saws.

2. Motor Power

Comparing the motor power of Delta and DeWalt table saws reveals important differences that directly impact their cutting performance.

Delta table saws are typically equipped with powerful motors designed for high-cutting performance, providing the necessary force to handle various materials. DeWalt, on the other hand, also features robust motors renowned for their power and efficiency.

When choosing between Delta and DeWalt table saws, consider the cutting tasks you’ll undertake. You can ensure optimal cutting results and overall performance by selecting a table saw with appropriate motor power.

3. Blade Controls

To explore the differences between these two table saws, let’s examine their distinct blade control mechanisms further.

DeWalt utilizes a plastic knob with a detent for blade control. This design offers a simplified approach to adjusting the blade tilt. Meanwhile, Delta employs a metal wheel for smooth blade height adjustment and a locking knob for the tilt mechanism, ensuring added stability.

When considering blade controls, consider your preferences for ease of use and precision. DeWalt’s plastic knob may provide a simpler adjustment process, while Delta’s metal wheel and locking knob may offer a more sturdy and precise control.

4. Cutting Capacity

Delta provides varying cutting capacities tailored to different materials and project requirements. This means you can choose a Delta table saw that offers the precise cutting capacity you need for your woodworking tasks.

Alternatively, DeWalt offers generous cutting capacities suitable for handling a variety of material sizes. This versatility allows you to work with a wide range of materials without worrying about the table saw’s cutting capacity limitations.

So, I recommend you assess the types of materials they frequently work with and choose a table saw that meets your cutting capacity needs to ensure efficient and precise cuts.

5. Saw Portability

Delta offers a variety of options to cater to different preferences. They’ve heavy and stationary models if you prioritize stability and durability. Additionally, they provide portable saws with wheels, allowing for easy transportation between job sites or within a workshop.

Conversely, DeWalt primarily focuses on portable designs, making it a more convenient choice if you prioritize mobility. Their table saws are designed to be lightweight and easy to transport, making them ideal if you frequently need to move your equipment.

6. Blade Fences

DeWalt table saws typically have a lightweight aluminum fence with a rack and pinion system. This allows for quick and precise adjustments, ensuring your cuts are accurate.

In contrast, Delta table saws feature a heavy-duty aluminum and steel fence. While this provides added sturdiness, it sacrifices collapsibility. This means the Delta fence is more stationary and less portable than the DeWalt option.

7. Noise Levels

DeWalt table saws are generally louder, comparable to typical job site saws, making them suitable if you work in noisy environments. These saws emit a higher noise level, which may disadvantage those seeking a quieter working experience.

On the other hand, Delta table saws are noticeably quieter, offering a more pleasant and less disruptive working environment. This makes them a preferred choice if you prioritize a quieter workspace.

So, I recommend considering the noise levels of these table saws to ensure they select the one that aligns with your specific needs and preferences.

8. Additional Features

If you prioritize convenience and portability, DeWalt table saws offer a quick and easy setup with folding legs, while Delta table saws boast a larger table space and a more robust design. DeWalt’s folding legs allow easy transportation and storage, making it ideal if you frequently move your tools.

On the other hand, Delta’s larger table space provides more support for larger workpieces, making it a better choice for those working on larger projects. Delta’s more robust design also ensures stability and durability, making it suitable for heavy-duty use.

9. Price Range

When comparing the price range of table saws, consider the varying options available from Delta and DeWalt. Delta offers various prices, catering to different budgets and preferences. Whether you’re a hobbyist or a professional woodworker, Delta has options to suit your needs.

On the other hand, DeWalt, known for its high-end and durable tools, also provides choices for budget-conscious consumers and professionals. So, you must align your budget with the features, build quality, and performance that meet your specific requirements.

Is the Delta table saw belt driven?

The Delta table saw has a belt-driven mechanism, allowing for low vibration and easy tensioning. This belt-driven system is a key feature of the Delta table saw that sets it apart from other models.

Using a belt to transfer power from the motor to the blade, the Delta table saw can achieve a smoother operation and reduce vibrations. This is particularly important if you require precision and accuracy in your woodworking projects.

The belt-driven mechanism also makes adjusting the blade’s tension easier, ensuring that it remains properly aligned and cutting smoothly. Additionally, the belt-driven design contributes to the overall durability and stability of the table saw, making it a reliable choice for both professionals and hobbyists alike.

Can I use a Dado blade on DeWalt table saws?

The Delta table saw’s belt-driven mechanism sets it apart from other models. Some DeWalt table saws are designed to accommodate dado blades, while others aren’t recommended for use with them.

For example, the DWE7402DI model allows stacked dado cutters for 10-inch blades. This means you can make wider cuts using multiple stacked blades. However, note that not all DeWalt table saws have this capability. For instance, the DWE7485 model isn’t recommended for use with dado blades.

It’s always important to consult the product user manual or contact the manufacturer to determine if a particular DeWalt table saw is compatible with Dado blades.

Are Delta table saws known for their powerful motors?

Delta table saws are widely recognized for their powerful motors, delivering exceptional cutting performance for various materials. Delta understands the importance of a robust motor in achieving efficient and precise cuts.

Many Delta table saws have motors ranging from 1.5 to 3 horsepower, providing ample cutting force to handle even the toughest materials. The powerful motors allow for smooth and consistent cutting, enabling you to tackle a wide range of projects easily.

Delta’s commitment to delivering powerful motors is evident in its attention to detail and quality construction. Their motors are designed to provide consistent power and performance, ensuring you can rely on their Delta table saws for years.

Delta or DeWalt: Choose the Best Table Saw for Your Woodworking

When choosing between Delta and DeWalt table saws, understanding the key differences is paramount for making an informed purchase. Whether the dimensions, blade controls, additional features, or purchase considerations, considering each aspect is vital when choosing a table saw.

By carefully evaluating these differences, you can confidently select the table saw that aligns with your preferences and project requirements minimizing related injuries. Ultimately, the choice between Delta and Dewalt table saws will depend on individual preferences and specific woodworking needs.

- Cordless and Corded Power Hybrid

- Automatic Voltage Change Technology

- 24″ Rip Capacity for Large Cuts

- Rack and Pinion Fence Adjustment

- Durable Metal Roll Cage Base

- Powerful 15 Amp Contractor Grade Motor

- Huge 25 Inch Rip Capacity

- Quick and Accurate Telescoping Rails

- Heavy Duty Fence Construction

- Professional-Grade 5-Year Warranty

Last update on 2026-03-01 / Affiliate links / Images from Amazon Product Advertising API