Crosscut Sled vs Miter Saw: 4 Primary Differences

When dealing with woodworking, precision, and safety are paramount for an accurate cutting. Two tools commonly used for making accurate cuts are the crosscut sled and the miter saw. While they both serve similar purposes, there are distinct differences between them that cater to various cutting needs and situations.

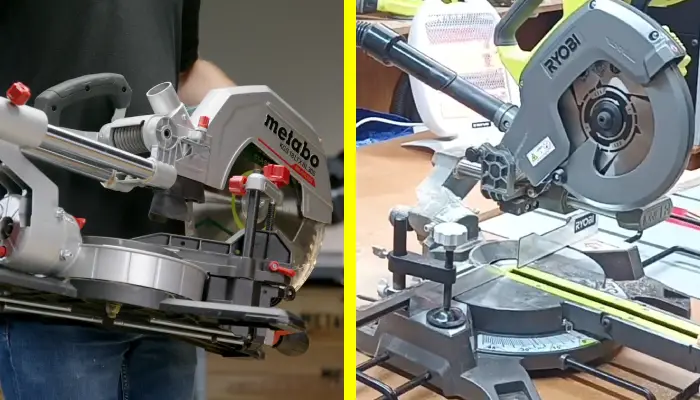

Crosscut sled & miter saw are primarily distinct in their design and functionality because a sled slides across the blade of a table saw at a 90-degree angle, ensuring square cuts. However, a miter saw is a dedicated cutting tool designed for accurate crosscuts and angled cuts.

Throughout this article, we will discuss the significant differences between these two woodworking tools and suggest what you should buy. So, keep reading for an in-depth discussion.

Significant Differences Between Crosscut Sled and Miter Saw

In terms of the design and functionality of a crosscut sled compared to a miter saw, there are some significant differences to consider.

- Design and functionality

- Versatility

- Accuracy and safety

- Workpiece size

Let’s discuss these in detail:

1. Design and Functionality

The crosscut sled provides a stable and secure platform for making accurate crosscuts and angled cuts across the grain of the wood.

This sled offers a larger base, providing stability and support for cutting larger workpieces. Its fence system and stops enable consistent and repeatable cuts of the same length, ensuring accuracy and efficiency.

Conversely, the miter saw is versatile and capable of cutting at various angles. It comes with a miter gauge that helps hold the workpiece at a set angle during cutting, allowing for easily angled cuts.

Miter saws are available in various types, including standard, compound, and sliding compound miter saws, catering to diverse woodworking needs.

2. Versatility

While crosscut sleds are excellent for making precise crosscuts and angled cuts, they are limited to use with a table saw. They are not as versatile as miter saws when handling different cuts.

With a miter saw you can quickly cut pieces at specific angles without adjusting a sled for each cut. This saves you time and effort, allowing you to focus on the task at hand. Whether you need to make compound miter cuts, bevel cuts, or even crosscuts, a miter saw can handle everything.

3. Accuracy and Safety

When comparing the crosscut sled and the miter saw, evaluating their performance in these aspects is important.

The crosscut sled offers exceptional accuracy, ensuring consistent and precise cuts every time. With its stable base, the sled minimizes the risk of the workpiece moving during the cut, ensuring safety.

The miter saw is also accurate, but there might be a slight risk of movement if the workpiece is not properly secured. Always ensure the workpiece is securely clamped or held down when using the miter saw to enhance safety.

4. Workpiece Size

When considering workpiece size, it’s important to evaluate the capabilities of each tool. A crosscut sled on a table saw is ideal for cutting larger workpieces that might be difficult to handle on a miter saw. The sled’s larger platform provides better support for bigger materials, ensuring stability and accuracy during the cut.

In contrast, miter saws are better suited for cutting smaller to medium-sized workpieces. While they can handle longer pieces to some extent, their cutting capacity might be limited compared to a crosscut sled on a table saw.

To give you a visual representation, here is a comparison table:

| Tool | Crosscut Sled on Table Saw | Miter Saw |

| Workpiece | Larger | Smaller |

| Support | Better | Limited |

| Stability | High | Moderate |

| Accuracy | Excellent | Good |

Do I need a crosscut sled if I have a miter gauge?

If you have a miter gauge, a crosscut sled may not be necessary, but it can still be a valuable tool in your workshop. While a miter gauge can cut various angles accurately, a crosscut sled offers additional benefits that enhance your woodworking experience.

Here are five reasons why a crosscut sled is worth considering:

- Improved safety: A crosscut sled provides better stability and control, minimizing the risk of kickback and ensuring accurate cuts.

- Increased precision: The sled allows for repeatable cuts with consistent accuracy, resulting in cleaner and more professional-looking workpieces.

- Enhanced versatility: With a crosscut sled, you can easily cut larger workpieces that may be challenging to handle on a miter gauge.

- Better control over thin or narrow stock: The sled’s zero-clearance design prevents small pieces from falling into the blade, ensuring cleaner cuts and reducing waste.

- Time-saving efficiency: Using a crosscut sled can streamline your workflow and make quick, precise cuts without constantly readjusting the miter gauge.

Why use a table saw crosscut sled instead of a miter saw?

Using a table saw instead of a miter saw allows you to make more precise and controlled cuts. When cutting workpieces, a crosscut sled is better than a miter gauge.

The miter gauge is limited in its capabilities, as it is small and can only handle certain cuts. Conversely, a crosscut sled has a larger base that supports the workpieces during the cut, ensuring that they do not make contact with the saw table.

This provides more stability and control, resulting in cleaner and more accurate cuts. Also, the larger base of the crosscut sled allows for better alignment and reduces the risk of kickback.

Therefore, if you want to achieve more precise and controlled cuts, a table saw with a crosscut sled is the way to go.

Is it better to push or pull a sliding miter saw?

When you push the miter saw blade into the wood, the workpiece presses against the fence against the cutting action, so there’s no climb cut. When using a sliding miter saw, it is better to push it through the wood than pull it. Here’s why:

- Better Control: Pushing the saw gives you better control over the cutting action, ensuring a more accurate and precise cut.

- Reduced Kickback: Pushing the saw reduces the risk of kickback, which can be dangerous and cause the workpiece to be thrown back toward you.

- Improved Safety: Pushing the saw keeps your hands away from the blade, minimizing the chance of accidental contact and potential injuries with the miter saw.

- Efficient Cutting: Pushing the saw allows for a smoother cutting motion, resulting in cleaner and smoother cuts.

- Consistent Results: Pushing the saw helps maintain consistent pressure against the fence, ensuring consistent and uniform cuts throughout your workpiece.

Which is better: sliding or non-sliding miter saw?

When deciding between a sliding or non-sliding miter saw, it’s important to consider each option’s cutting capacity and flexibility. Sliding miter saws have a distinct advantage when cutting wider boards.

The sliding bars or arms allow the blade to travel forward over the board, giving you a larger cutting capacity. You can easily tackle larger projects and make wider cuts without issues.

Conversely, non-sliding miter saws are more compact and lightweight, making them easier to maneuver and transport. They are also generally more affordable compared to sliding miter saws. However, they have a limited cutting capacity and are suitable for smaller projects or when you don’t need to make wide cuts.

Can I get a kickback in a crosscut sled?

To minimize the risk of kickback, you’ll want to ensure that your crosscut sled is properly aligned and securely held in place. Kickback can occur when the cut wood gets caught in the blade and is forcefully thrown back toward the operator. However, the risk of kickback is very unlikely when using a crosscut sled.

The sled provides a stable and controlled cutting surface, reducing the chances of the wood binding or getting caught in the blade. Here are some important factors to consider when using a crosscut sled:

- Ensure that the sled is securely attached to the table saw’s miter gauge or fence.

- Check that the sled’s runners are aligned with the saw’s miter slots.

- Use a hold-down or toggle clamp to keep the workpiece in place while cutting.

- Ensure the blade is sharp and in good condition to prevent any wood from binding.

- Always maintain a firm grip on the workpiece and always keep your hands clear of the blade.

Do I need a riving knife with a crosscut sled?

While using a crosscut sled with a riving knife is recommended for added safety, it is not always necessary depending on the task. A riving knife is a thin, metal plate that sits just behind the blade and helps prevent kickback by keeping the kerf open as the wood is cut.

It is particularly useful when working with larger or thicker wood pieces with a higher risk of binding or pinching the blade. But a riving knife may not be essential for smaller, thinner pieces or simple crosscuts, where the risk of kickback is minimal.

What is the best base for a crosscut sled?

The recommended choice for the base of a crosscut sled is 1/2′ MDF. This material is sturdy and flat, ensuring a stable and accurate cutting surface. When building your crosscut sled, it’s important to consider the following:

- Safety: Using a solid and stable base like 1/2′ MDF reduces the risk of kickback and provides a secure platform for your workpiece.

- Precision: MDF is known for its smooth and flat surface, allowing for precise and accurate cuts.

- Durability: MDF is a durable material that can withstand regular use without warping or breaking.

- Cost-effectiveness: 1/2′ MDF is an affordable option for constructing a crosscut sled compared to other materials.

- Ease of customization: MDF is easy to work with, allowing you to customize your crosscut sled to fit your needs.

Crosscut Sled or Miter Saw: Choose the Perfect Cutting Companion for Your Woodworking Projects

The choice between a crosscut sled and a miter saw largely depends on the nature of your woodworking projects and your preferred tools.

Crosscut sleds offer exceptional accuracy and stability for crosscuts on a table saw, particularly for larger workpieces. Alternatively, miter saws are versatile cutting tools designed specifically for crosscuts and angled cuts, making them a go-to choice for various woodworking tasks.

Ultimately, having both tools in your woodworking arsenal can give you the flexibility to tackle a wide range of projects with precision and ease.