Can You Cut Aluminum With a Table Saw: Find Out the Fact [Important]

Have you ever wondered if you can cut aluminum with a table saw? You totally can. To cut aluminum with a table saw, ensure the blade is aligned and secure, and adjust the blade height.

Then mark your cut line on the aluminum, lubricate the blade, and carefully feed the aluminum through the saw blade using a push stick or hold-down stick. Once the cut is complete, remember to clean up any aluminum shavings or debris.

We will provide you with a detailed guide on how to expertly cut aluminum using a table saw. Keep reading to understand all the necessary steps.

How to Cut Aluminum Using a Table Saw? Steps to Follow

The following is a quick guide to cutting aluminum with a table saw:

Step #1: Prepare the table saw

Step #2: Mark your cut line

Step #3: Lubricate the blade

Step #4: Feed the aluminum into the saw

Step #5: Clean up

Let’s go over the detailed steps:

Step #1: Prepare the Table Saw

Make sure your table saw is set up correctly before cutting aluminum. Begin by aligning and securely mounting the blade.

Ensure that the blade is level and perpendicular to the table. A misaligned blade can cause inaccurate cuts, increase the risk of injury, and damage the blade.

Next, adjust the blade height to suit the thickness of the aluminum you’ll be cutting. The blade should be set so that only the teeth are visible above the material being cut. Too high or too low a setting can cause the blade to bind, overheat, or damage the cut material.

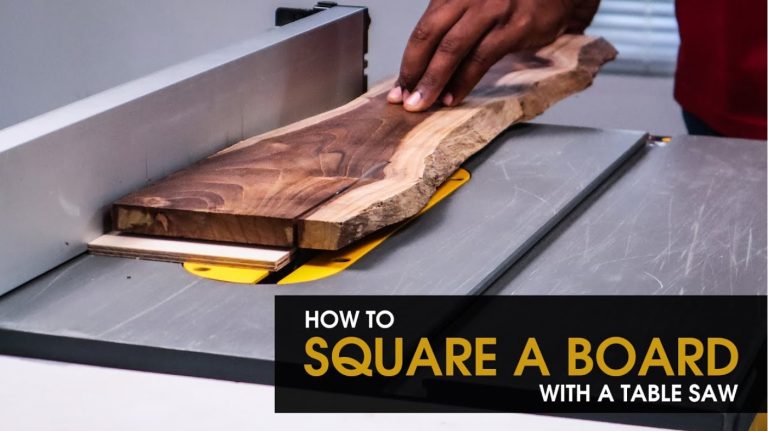

Step #2: Mark Your Cut Line

Grab a measuring tape and straightedge to accurately mark where you want to slice through that shiny metal, using a marker that’ll stick despite the surface’s slickness.

To ensure that your cut stays in line, consider using clamps or a fence to guide the material through the blade. This will help you achieve a straight and consistent cut.

Another important thing to remember is to wear appropriate safety gear, such as goggles and gloves.

Step #3: Lubricate the Blade

To prevent the aluminum from sticking and reduce friction, you need to apply a lubricant to the teeth of the blade before cutting.

This not only makes the cutting process smoother but also prevents damage to both the blade and the aluminum. When choosing a lubricant, cutting oil or WD-40 are both excellent options.

Step #4: Feed the Aluminum Into the Saw

As you position the marked cut line on the table saw, align it with the blade and use a push stick to guide the aluminum through smoothly. Make sure to keep your hands safely away from the blade at all times.

Here are some additional tips to help you feed the aluminum into the saw:

- Use a steady feed rate: Maintaining a consistent pace as you push the aluminum through the saw blade is important. This will help ensure a smooth and accurate cut. Avoid pushing too quickly or too slowly, as this can lead to uneven cuts or even damage to the blade.

- Avoid forcing the aluminum: Let the saw do the work for you. Don’t try to push the aluminum through the blade with excessive force, as this can cause kickback or damage to the workpiece. Instead, let the saw blade cut through the aluminum at its own pace.

- Use additional support for long or heavy pieces: If you’re cutting long or heavy pieces of aluminum, it may be helpful to have additional support or an outfeed table to prevent the aluminum from sagging or falling during the cut. You’ll get a smoother, more accurate cut and it helps keep you safe while working.

Step #5: Clean Up

After completing the cut, turning off the table saw and properly disposing of any debris is essential.

Aluminum shavings and waste material can accumulate quickly, so cleaning the work area is crucial to prevent accidents or injuries.

Use a brush or vacuum to collect the shavings and dispose of them in a designated aluminum waste container. Remember, aluminum is 100% recyclable, so make sure to recycle any scraps or waste material properly.

What type of blade should you use to cut aluminum on a table saw?

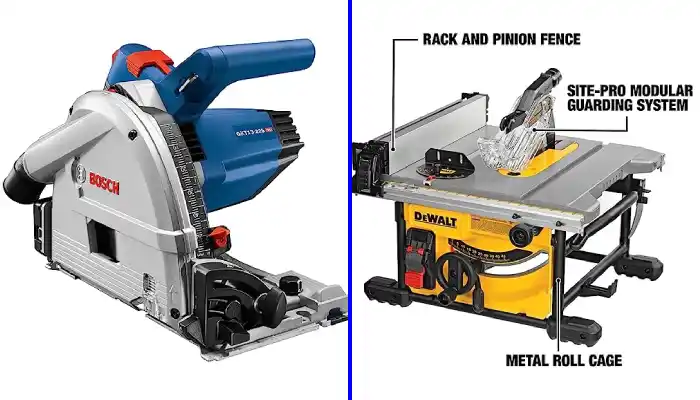

To cut aluminum on a table saw, you need to use a blade that is specifically designed for non-ferrous metals like aluminum.

A suitable blade for cutting aluminum usually has a high tooth count and is made of carbide or other appropriate materials.

Remember that using the wrong type of blade may result in suboptimal cuts and even damage to the table saw. So, investing in a specialized blade for the task is always better to ensure effective and efficient cuts.

How do I prevent kickback when cutting aluminum on a table saw?

You’ll need to align and set the blade correctly and use a hold-down stick or push stick to guide the metal through the cut to prevent kickback and ensure your safety.

Kickback can occur when the blade grabs the aluminum and throws it back toward the operator, causing serious table saw injury.

To prevent this, make sure the blade is aligned with the fence and set at the appropriate height for the thickness of the aluminum.

Take care to feed the aluminum steadily and avoid forcing it through the blade. Forcing the metal can cause it to bind or catch on the blade, increasing the risk of kickback. Instead, let the blade do the work and guide the aluminum through the cut with steady pressure.

Always wear eye and ear protection, and never remove the blade guard or anti-kickback pawls. These precautions allow you to safely and effectively cut aluminum on a table saw.

What is the maximum thickness of aluminum that can be cut on a table saw?

The maximum thickness of aluminum you can cut on a table saw is usually 1/4 inch (0.25 inches or 6.35 mm). But, this can vary depending on the specific table saw’s power, blade, and capacity.

It is vital to refer to the manufacturer’s guidelines and specifications to determine the recommended maximum thickness for cutting aluminum for your specific table saw.

Some heavy-duty table saws with more powerful motors and larger blades may be able to cut thicker aluminum materials, such as up to 1/2 inch (0.5 inches or 12.7 mm).

It is essential to ensure that the table saw is appropriately set up, the blade is appropriate for cutting aluminum, and safe-cutting practices are followed when working with thicker aluminum materials to maintain both accuracy and safety.

Cut Aluminum With a Table Saw Like a Pro

You now know how to cut aluminum with a table saw. When you follow the steps outlined and use the appropriate blade, you can easily make precise cuts.

To recap, you need to use a carbide-tipped blade with a high number of teeth to ensure a clean cut. Also, take extra caution to prevent kickback by using a push stick and ensuring the blade is properly aligned.

Remember, the maximum thick aluminum you can cut with a table saw will vary depending on the saw and blade used. Always refer to the manufacturer’s guidelines and use proper safety measures to avoid injury. So go ahead, grab your saw, and work on your next aluminum project.