Can a 7.25 Skill Saw Cut a 4×4? Things You Need to Know

You can cut a 4×4 with a 7.25-inch Skill saw, but it won’t cut all the way through in one pass—its maximum depth is about 2.5 inches, less than the 3.5-inch thickness of a 4×4.

To get a full cut, you’ll need to secure the timber, mark all sides, make multiple passes, and carefully realign the wood each time. Proper technique and safety are essential, and exploring more about these will improve your cutting process.

Key Takeaways

- A 7.25-inch Skill Saw’s maximum cutting depth (~2.5 inches) cannot cut a full 4×4 (3.5 inches) in one pass.

- Cutting a 4×4 with this saw requires multiple passes and rotating the lumber to complete the cut.

- Mark all four sides of the 4×4 for accuracy before cutting and secure it firmly with clamps.

- Safety gear like eye protection and stable support are essential when making multiple cuts on thick lumber.

- For cleaner, faster cuts, consider larger saws like 10-inch table saws or 12-inch miter saws instead.

Cutting Capacity of a 7.25-Inch Skill Saw

While a 7.25-inch Skill Saw is a versatile tool for many woodcutting tasks, its cutting depth is limited to around 2.5 inches at a 90-degree angle, which falls short of the 3.5-inch thickness of a standard 4×4 lumber.

This means you can’t make a full cut through a 4×4 in a single pass. The saw’s 15-amp motor and 5,300 RPM provide high power and speed but do not increase the cutting depth beyond the blade size.

Beveling the blade reduces cutting depth further; at 45 degrees, expect about 1.75 inches maximum. The blade diameter restricts how deep you can cut, regardless of motor power, which typically runs around 15 amps and 5,300 RPM.

To fully cut a 4×4, you’ll need to make multiple passes or reposition the material. Understanding these limits helps you plan safe, accurate cuts with your 7.25-inch saw. It is also important to adjust the blade height properly to ensure a clean and safe cut.

Dimensions and Challenges of Cutting a 4×4 Lumber

Because the actual dimensions of 4×4 lumber measure 3½ inches by 3½ inches, cutting through it requires a saw blade depth that exceeds this thickness for a complete crosscut.

The nominal 4×4 size reflects rough cut dimensions before drying and planing, which reduces thickness to the standardized 3½ inches per PS 20-20. This thickness challenges saws with blades under 4 inches, often demanding multiple passes or precise alignment to avoid splintering.

You’ll also need to manage the lumber’s weight and size carefully, ensuring stable support during cutting. Using a blade with inadequate depth can result in incomplete cuts and increased kickback risks.

4×4 lumber is commonly made from pine, fir, and spruce, known for their strength and durability in structural applications. Dimensional accuracy matters here, as slight measurement errors affect joint fit and structural integrity.

Techniques for Successfully Cutting a 4×4 With a 7.25-Inch Saw

Since a 7.25-inch circular saw’s maximum cutting depth is about 2.5 inches, you can’t make a full cut through a 4×4 post in a single pass.

Start by accurately measuring and marking the cut line with a speed square, wrapping the mark around the post for alignment. Marking lines on all four sides ensures the cut stays consistent and straight.

Secure the 4×4 firmly on sawhorses using clamps to prevent movement. Make the first cut along the guideline on one side.

Then, rotate the post 180°, realign the blade with the original mark, and perform the second cut, slightly overlapping the first to ensure full penetration. Using a saw with blade controls and adjustments can help improve cutting precision and stability.

After cutting, inspect for any uncut fibers at the center and trim if necessary. This two-pass method guarantees a clean, precise cut despite the blade’s limited depth.

Safety Precautions and Best Practices During Cutting

Before you start cutting, always prioritize safety by equipping yourself with the proper personal protective gear. This includes eye protection, hearing protection, a dust mask, fitted clothing, and secured long hair. It is also crucial to avoid wearing gloves, as they can increase the risk of accidents by getting caught in the blade.

Next, inspect your 7.25-inch skill saw thoroughly—check the blade’s sharpness, tightness, and guard function. Also, confirm the blade rotates correctly before use.

Securely clamp the 4×4 on a stable surface to prevent movement. Using a riving knife can further enhance safety by reducing the chance of kickback. Always use two hands to keep control, standing to the side of the cut to reduce kickback risk.

Allow the saw to reach full speed before cutting and avoid forcing it.

- Wear eye and hearing protection

- Secure the wood firmly with clamps

- Use two hands to maintain control

- Check saw and blade condition before use

- Stand clear of the blade’s path during operation

Alternative Tools for Efficient 4×4 Cutting

When you need to cut a 4×4 efficiently, selecting the right tool can make all the difference in speed, accuracy, and safety.

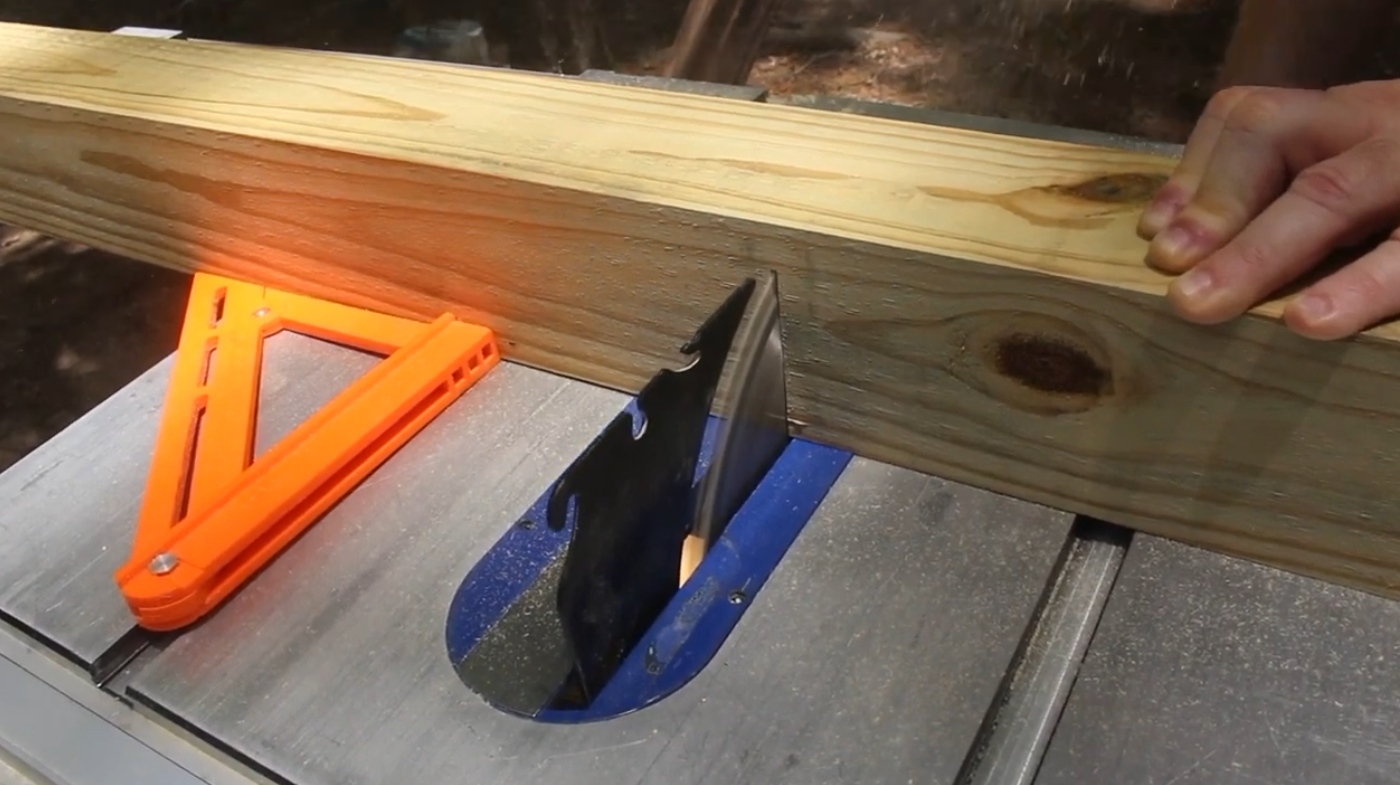

A 10-inch table saw offers precise, stable cuts through the full 3.5-inch thickness, ideal for straight cuts with proper setup. However, because 4x4s are heavier and tougher, maneuvering them on a table saw can be challenging. Using a saw with a rear handle design can improve control during these heavier cuts.

For angled cuts, a 12-inch miter saw handles 4x4s in a single pass, though 10-inch models require flipping the post.

Circular saws demand multiple passes and careful handling to avoid binding but remain portable options. Reciprocating saws excel in tight spaces and rapid demolition cuts, sacrificing precision.

Traditional handsaws provide fine control without power but need significant effort. Match your tool choice to project demands for perfect efficiency and safety when working with 4×4 lumber.

Frequently Asked Questions

How Often Should I Replace the Blade When Cutting 4x4s?

You should replace your blade after every 10 to 15 full 4×4 cuts to maintain cutting efficiency during typical DIY or light professional work.

If you’re a contractor handling higher volumes, expect to swap blades more often, around 5 to 7 cuts. Always inspect the blade’s sharpness after each project, and watch for signs like burn marks or rough cuts. Sharpen or replace blades midway if you’re doing continuous cutting sessions.

Can I Use a 7.25-Inch Saw to Cut Treated Lumber Safely?

Think of your 7.25-inch saw as a precise scalpel rather than a broad axe when cutting treated lumber. You can safely use it if you work in a well-ventilated area, wear proper protective gear like masks and goggles, and verify the blade is sharp and carbide-tipped.

Cut slowly with multiple passes to avoid overheating, and secure the wood firmly. Proper cleanup of treated dust is essential to protect your health and environment.

What Type of Blade Tooth Count Is Best for Cutting 4x4s?

For cutting 4x4s, you want a blade with about 24 teeth, ideally an ATBR (Alternating Tooth Bevel Raker) design. This setup efficiently clears large wood chips and balances cut speed with smoothness.

Carbide-tipped blades are best for durability, especially on treated or hardwood 4x4s. Avoid very high tooth counts (40+), as they slow cuts and aren’t necessary for rough lumber. Keep your blade sharp for consistent performance.

How Do Weather Conditions Affect Cutting Performance With a 7.25 Saw?

Weather affects your 7.25 saw like a thermostat controls an engine’s efficiency. Cold thickens lubricants and hardens wood, increasing resistance and kickback risk.

Heat may warp blades and clog dust, reducing cut quality. High humidity toughens wood and risks blade rust, while wind can blow debris into your motor, causing wear.

At altitude, thinner air lessens cooling, raising overheating risks. You must adjust technique and maintenance to maintain precision.

Is It Possible to Cut 4x4s Without Clamps Using a 7.25 Saw?

You can cut 4x4s without clamps using a 7.25-inch saw by securing the post against a stable surface like the ground or a workbench.

Mark your cut lines clearly on opposing sides, then make two passes—rotating the post 180° between cuts. Use your body weight to stabilize the wood and maintain a firm grip on the saw. Always prioritize safety gear and control to reduce kickback risk.

Safe, Clean Cuts Are All About Technique

You can cut a 4×4 with a 7.25-inch Skill Saw, but only by making multiple passes since its 3-inch maximum cutting depth is less than the 3.5-inch thickness of the lumber.

Notably, professional carpenters often make up to three passes to achieve a clean cut without overloading the saw. Always prioritize safety by securing the wood firmly and wearing protective gear. For faster, more efficient cuts, consider a 10-inch saw or a miter saw designed for thicker materials.