Vertical vs Horizontal Band Saw: 9 Differences

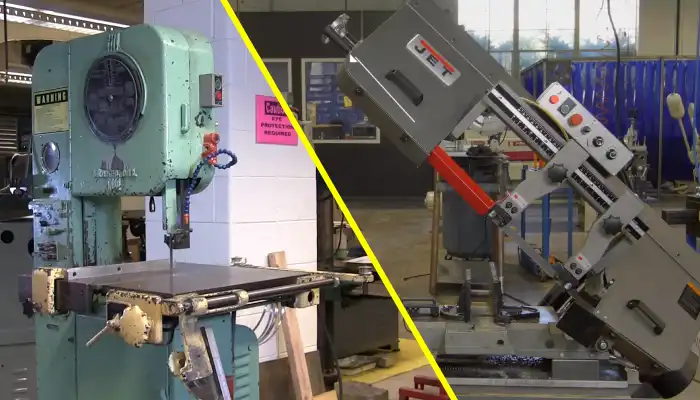

In woodworking and metalworking, band saws are available in two primary configurations: vertical and horizontal. Each type possesses distinct features catering to specific needs within these crafts. And for successful woodworking projects, I’ve found that choosing the right band saw is crucial.

A vertical band saw allows for intricate curved cuts, while the horizontal band saw excels at straight cuts. In the vertical band saw, the blade stays stationary while the workpiece moves, but in the horizontal band saw, the blade moves while the workpiece stays put.

Here, I will discuss the technical aspects and functionalities of vertical and horizontal band saws. Comparing their cutting orientation, flexibility, safety features, precision, and detail can help you make an informed decision.

- Powerful 3.5 amp motor

- Dual-speed operation (1520/2620 FPM)

- 72-inch blade compatibility

- Adjustable 14×12.5 inch work table

- Includes work light and dust port

- Large Cutting Capacity, Versatile Use

- Powerful 1100W Pure Copper Motor

- Ergonomic Design, Comfortable Operation

- Adjustable Base, Precise Angle Cuts

- High-Speed Cutting, Smooth Performance

Differences Between Vertical and Horizontal Band Saw

As a woodworking enthusiast, I appreciate the differences between vertical and horizontal band saws in wood-based projects. According to my findings, here are some of the key distinctions:

- Cutting orientation

- Blade position and movement

- Cutting flexibility

- Blade variety

- Cutting speed and rate

- Blade control and visibility

- Precision and detail

- Size and workshop suitability

- Cost considerations

No 01: Cutting Orientation

I prefer using a vertical band saw for wood-based projects due to its versatile cutting orientation. The blade’s vertical movement allows for intricate and detailed cuts, making it ideal for tasks that require precision and finesse.

Whether it’s scrollwork or crafting ornate designs, the vertical band saw excels in creating intricate patterns and shapes in wood.

Conversely, horizontal band saws have a horizontal cutting orientation. This orientation is more geared towards quickly and efficiently slicing through wood precisely. This makes them well-suited for tasks like cross-cutting and ripping.

No 02: Blade Position and Movement

The stationary blade in a vertical band saw allows for greater control and precision when cutting intricate shapes or curves in the wood. The wood is fed into the blade, and the operator can manipulate the wood to achieve the desired cut.

This setup is especially useful for making precise cuts in smaller wood pieces or creating detailed designs.

On the other hand, the horizontal band saw has a blade that moves through a stationary wood piece. This allows for faster cutting of large pieces of wood, as the blade can make continuous, straight cuts without the need to maneuver the wood. The horizontal band saw is ideal for cutting thick lumber or making long, straight cuts.

No 03: Cutting Flexibility

Vertical band saws, with their ability to move the blade upward, offer enhanced maneuverability and are well-suited for tasks that involve navigating tight curves and angles. This increased flexibility allows for intricate and complex cuts, making vertical band saws ideal for projects that require precision and detailed work.

Alternatively, horizontal band saws have a more rigid cutting path and excel in straight cuts. While they may not be as versatile as vertical band saws, their strength lies in consistently producing clean and straight cuts. This makes them suitable for projects prioritizing accuracy and efficiency over intricate designs.

No 04: Blade Variety

The blade variety differs between vertical and horizontal band saws for wood-based projects. Vertical band saws offer wider blade options than their horizontal counterparts. This is due to the flexibility and versatility of vertical band saws designed to accommodate narrower blades.

These narrower blades are ideal for detailed work and intricate cuts, making them suitable for tasks that require precision and intricate designs.

As an alternative, horizontal band saws typically use wider blades, prioritizing efficiency in straight cuts. The wider blades of horizontal band saws allow for higher cutting rates and are well-suited for tasks that require speed and productivity.

No 05: Cutting Speed and Rate

Vertical band saw cutting speeds are variable. This allows for flexibility in adjusting to different wood densities and achieving optimal cutting rates for specific tasks. This feature makes them suitable for projects that require precision and control.

On the other hand, horizontal band saws are known for their consistent and high cutting rates. They’re designed to process large quantities of wood efficiently, making them ideal for projects that require speed and productivity.

No 06: Blade Control and Visibility

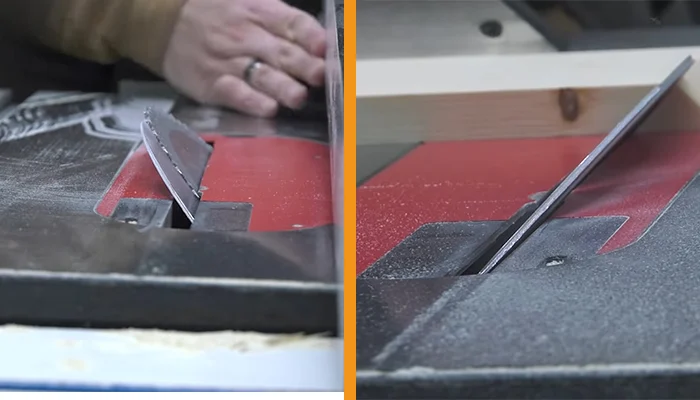

Based on my findings, the wood is positioned above the blade in a vertical band saw, allowing for excellent visibility and control. This means you can easily see the blade as it cuts through the wood, making it easier to follow your desired path and make precise cuts.

Additionally, the vertical orientation of the blade provides better control over the cutting process, allowing for more accurate and controlled cuts.

In contrast, the wood is placed on the same plane as the blade in a horizontal band saw, which may slightly reduce visibility. However, with proper lighting and positioning, you can still achieve good visibility and control over the cutting process.

No 07: Precision and Detail

Vertical band saws are known for their exceptional precision and ability to produce intricate details in woodworking projects. Their design allows for a perpendicular cutting motion, which provides greater control and visibility. Vertical blades make it easier to follow intricate patterns and curves.

Additionally, vertical band saws often have smaller blades, which further enhances their ability to make precise cuts.

Contrary to this, horizontal band saws prioritize efficiency and speed over detailed precision. They’re better suited for tasks that require straight cuts and high-volume production. The horizontal orientation of the blade and larger size make it more challenging to achieve the same level of precision as vertical band saws.

No 08: Size and Workshop Suitability

Vertical band saws, being smaller in size, are highly space-efficient and thus ideal for smaller woodworking shops or workshops with limited space. Their compact design allows for easy maneuverability and placement in tight spaces.

On the other hand, horizontal band saws, although larger, are better suited for larger workshops with ample space. These saws are specifically designed to handle larger wood pieces and require a larger working area to accommodate their size and cutting capacity.

No 09: Cost Considerations

I found that comparing the cost considerations between vertical and horizontal band saws for wood-based projects was a valuable exercise.

Regarding cost, vertical band saws tend to be more affordable, making them an attractive option for smaller carpentry businesses or hobbyists on a budget. You can choose 14-inch band saws because they are generally less expensive.

This makes them a cost-effective choice for those who don’t require the advanced features and cutting capabilities of a horizontal band saw.

Alternatively, horizontal band saws may have a higher initial cost but offer increased efficiency and cutting capabilities. This makes them a worthwhile investment for larger woodworking operations focused on productivity.

While the upfront cost may be higher, the long-term benefits and productivity gains can outweigh the initial expense.

Comparison Table Between Vertical and Horizontal Band Saw

| Criteria | Vertical Band Saw | Horizontal Band Saw |

| Cutting Orientation | Vertical movement for intricate cuts | Horizontal orientation for efficient slicing |

| Blade Position/Movement | Stationary blade; wood fed into the blade | Moving blade through stationary wood for straight cuts |

| Cutting Flexibility | Enhanced maneuverability for tight curves | More rigid cutting path; excels in straight cuts |

| Blade Variety | Wider blade options for versatility | Typically uses wider blades for efficiency |

| Cutting Speed/Rate | Variable cutting speeds for flexibility | Consistent high cutting rates for efficiency |

| Blade Control/Visibility | Wood positioned above blade; excellent visibility | Wood on the same plane as blade; slightly reduced visibility |

| Precision and Detail | Exceptional precision for intricate details | Prioritizes efficiency over detailed precision |

| Size and Workshop Suitability | Smaller, space-efficient; ideal for smaller workshops | Larger size; better suited for larger workshops |

Can I use a vertical band saw for ripping large wooden boards?

Using a vertical band saw for ripping big wooden boards may not be the most efficient or precise option. Vertical band saws are primarily designed for cutting curves and intricate shapes in smaller pieces of wood. As I know, a horizontal band saw is a better choice for ripping due to its blade orientation and movement.

Horizontal band saws have a flat table that supports the workpiece, allowing for more stability and control during the ripping process. Additionally, the horizontal movement of the blade provides a straighter cut compared to the vertical movement of a vertical band saw.

How do I troubleshoot blade chatter issues on a horizontal band saw?

To troubleshoot blade chatter on a horizontal band saw, I recommend checking the blade tension alignment of the guides. You should inspect the blade tensioner, blade guides, and drive wheels for damage or wear.

Improper blade tension can cause the band saw blade to vibrate and produce chatter during cutting. Ensure that the blade is tensioned according to the manufacturer’s recommendations.

Incorrect alignment of the guides can also contribute to blade chatter. Make sure that the guides are properly adjusted and aligned with the blade.

Additionally, inspect the blade for any signs of damage or wear, such as missing teeth or dullness. Replace the blade if necessary to eliminate chatter and ensure smooth cutting.

Vertical or Horizontal Band Saw: Invest in One

I hope you now understand the differences between vertical and horizontal band saws are crucial for wood-based projects.

While a vertical band saw is great for intricate cuts and curves, it may not be suitable for ripping large wooden boards. On the other hand, a horizontal band saw is ideal for ripping and resawing tasks.

Investigating blade chatter issues on horizontal band saws is important to ensure smooth and accurate cuts. Don’t forget that the right tool for the job can make all the difference in woodworking projects.

- Powerful 2.8 Amp Induction Motor

- 2-Speed Drive System for Versatility

- Quick Blade Tension Setting

- Rack and Pinion Table Adjustment

- Dust Port for Clean Workspace

- Powerful 10-Amp Motor for Precision Cuts

- Variable Speed from 60 to 420 FPM

- Huge 5×5 Inches Cutting Capacity

- Lightweight and Portable at 14.5lbs

- Two-Year Warranty for Peace of Mind

Last update on 2026-02-02 / Affiliate links / Images from Amazon Product Advertising API