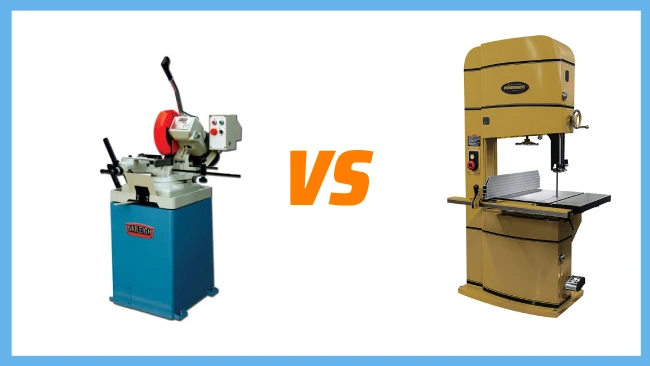

Cold Saw vs Band Saw: 10 Differences

As a woodworking enthusiast, I’ve been curious about the differences between the cold and band saw for wood-based projects. These two tools, with their contrasting cutting techniques, offer unique advantages in terms of precision and efficiency. But what sets them apart?

The cutting mechanism sets them apart, with the cold saw utilizing a circular blade and the band saw employing a continuous loop of toothed blades. Band saws produce good-quality cuts but lack the smoothness and precision of cold saws.

Join you on this insightful exploration as I dive into the depths of the cold saw and the band saw. Here, I’ll break them down so you can decide which one reigns supreme in woodworking based on kerf size, cutting speed, noise level, and more.

- Powerful 2.5-hp Motor for Chatter-Free Cuts

- Versatile 45-Degree Mitering Capability

- Rigid Cast Iron Base for Stability

- Efficient European-Style Taper Lock Vise

- Integrated Coolant Pump Enhances Blade Life

- Powerful 2.8-Amp Motor

- Versatile 9-Inch Cutting Capacity

- Adjustable 45-Degree Bevel Table

- Convenient 2.5-inch Dust Port

- Dependable Ball-Bearing Blade Support

Differences Between Cold Saw and Band Saw for Wood-Based Projects

Several key differences exist when comparing a cold saw and band saw for wood-based projects. Here, I listed a few important elements to consider.

- Cutting mechanism

- Material versatility

- Kerf size

- Cut finish

- Cutting speed

- Blade maintenance

- Size and portability

- Precision in straight cuts

- Noise level

- Safety considerations

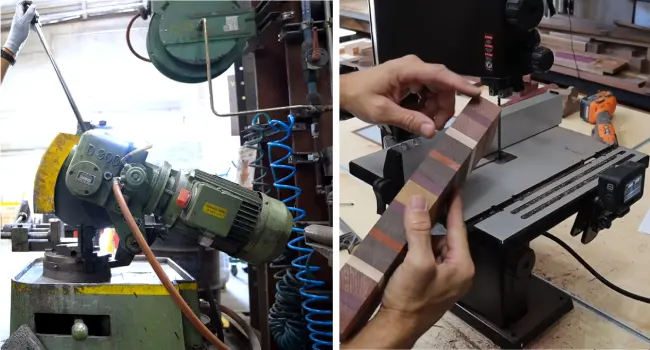

No 01. Cutting Mechanism

The circular blade of a cold saw rotates at low speeds, resulting in minimal friction and heat during cutting. This reduces the risk of damaging the wood and ensures clean and smooth cuts. The blade’s slow rotation also allows for greater control, making it easier to follow precise lines and curves.

In contrast, a band saw utilizes a continuous loop of toothed metal, which can sometimes cause rougher cuts and require additional finishing. Also, depending on the material and cut thickness, a band saw may require more force and cause extra vibration.

While a band saw offers more versatility in cutting irregular shapes, I prefer a cold saw for high-quality, professional wood-cutting results.

No 02. Material Versatility

Cold saws are primarily designed for cutting hardwoods and dense materials. Their robust construction and effective cutting make them suitable for handling thicker and denser wood with ease.

On the other hand, band saws offer a higher level of versatility for wood types. They excel in cutting a variety of wood, including both softwoods and hardwoods. This adaptability allows for intricate designs and curved cuts.

This makes the band saw a valuable tool in carpentry workshops where a wide range of wood materials must be cut into complex shapes. The bandsaw also excels in cutting thin wood pieces like veneers and laminates.

No 03. Kerf Size

The kerf refers to the width of the cut made by the saw blade. Wood-cutting band saws typically have a smaller kerf size compared to band saws. These saws use thinner blades that remove less material during cutting. The advantage of a smaller kerf size is that it results in higher efficiency and less waste in carpentry projects.

Contrary to this, cold saws have a wider kerf due to the nature of their blade. While this may lead to more material waste, it also allows for greater smothness when cutting intricate patterns and curves.

No 04. Cut Finish

With its milled-like finish, the cold saw offers a significant advantage in carpentry. This finish eliminates the need for additional sanding or finishing processes, saving valuable time and effort in creating high-quality woodwork.

Meanwhile, the finish produced by a band saw is generally rougher. This roughness requires additional steps for smoothing and refining the wood surface.

I think, depending on your project’s finishing needs, this difference in cut finish becomes a crucial factor.

No 05. Cutting Speed

Band saws typically have a higher tooth count, allowing them to cut through wood at a quicker pace. This is especially advantageous when working on larger projects that require multiple cuts.

A band saw’s faster cutting speed saves time and improves efficiency, making it easier to complete woodworking tasks within a given timeframe.

The faster cutting capacity of the band saw also reduces the chances of the wood burning or splintering, resulting in cleaner and smoother cuts.

Alternatively, cold saws operate at lower speeds, contributing to their ability to produce precise cuts. However, this slower pace might lead to a longer processing time, especially for larger woodworking projects.

No 06. Blade Maintenance

As I know, the cold saw offers more advantages when it comes to blade maintenance. Cold saw blades are designed to be durable and can be resharpened, which significantly extends their lifespan. This saves costs in the long run and ensures consistent and precise cuts throughout the blade’s life.

On the other hand, band saw blades are often disposable and need to be replaced when they become dull. When choosing a band saw for wood-based projects, this recurring cost should be considered.

However, advancements in blade technology have introduced longer-lasting band saw blades, providing woodworkers with more cost-effective solutions. You can choose bandsaw under 1000 to get the best value for money.

No 07. Size and Portability

Cold saws are designed to be compact and lightweight, making them highly portable and easy to maneuver within a carpentry workshop. Their smaller size allows them to fit into tight spaces and makes them a practical choice for workshops with limited room.

In contrast, band saws tend to be larger and heavier, requiring more space for installation and operation. While this may limit their portability, it comes with the advantage of a larger cutting capacity, allowing for the processing of larger wood pieces.

No 08. Precision in Straight Cuts

Regarding straight cuts, the cold saw is the clear winner regarding accuracy.

Since it is specifically designed to provide precise cuts in wood, it is ideal for projects requiring high levels of precision, such as furniture making or cabinetry. Its rigid and sturdy construction ensures that the blade remains stable during cutting, resulting in clean and straight cuts.

Alternatively, while band saws may struggle to match the precision of cold saws in straight cuts, they excel in curved and irregular cuts. This makes them a better fit for projects prioritizing intricate designs over straight lines.

No 09. Noise Level

Cold saws are known for producing less noise during operation, making them ideal for creating a quieter and more comfortable working environment in a carpentry shop. Their design, with their toothed blades and slow rotational speed, helps to minimize the noise generated during cutting.

However, band saws can be noisier, especially when cutting denser or thicker wood. This is due to the continuous cutting action of the bandsaw blade, which can create more vibrations and noise.

I advise considering the noise level the saw produces when considering overall working conditions in a carpentry shop.

No 10. Safety Considerations

According to my findings, cold saws have safety features that prioritize the user’s well-being. With lower operating speeds, the risk of accidents is significantly reduced. The slower cutting motion allows for better control and precision, minimizing the likelihood of injuries.

Conversely, band saws require extra caution due to their higher cutting speeds. Proper training and protective equipment are crucial to ensure safe operation in a carpentry workshop when operating a bandsaw. It’s important to follow all safety guidelines, such as safety glasses and clothing, to protect against potential hazards.

Additionally, regular maintenance and inspection of both saw types are necessary to identify any potential safety issues and address them promptly. Safety should always be the top priority when working with power tools in a woodworking environment.

Comparison Table Between Cold Saw and Band Saw

| Criteria | Cold Saw | Band Saw |

| Cutting Speed | Low speeds, reducing friction and heat | Faster Cut with a continuous loop of toothed |

| Material Versatility | Designed for cutting hardwoods and dense materials | Higher level of versatility for wood |

| Kerf Size | Smaller kerf size | Wider kerf size |

| Cut Finish | Milled-like finish | Generally rougher finish |

| Blade Maintenance | Blades can be resharpened, extending their lifespan | Blades are often disposable and need to be replaced when dull |

| Size and Portability | Compact and lightweight, highly portable | Larger and heavier, requiring more space for installation |

| Precision in Straight Cuts | Ideal for high levels of precision | Excels in curved and irregular cuts. |

| Noise Level | Produces less noise during operation | Can be noisier, especially when cutting denser or thicker wood |

Why is it called a cold saw?

The term ‘cold saw’ refers to a type that operates without flood coolant, as the heat generated during cutting is transferred to the chips. Cold saw blades are specifically designed for cutting materials at lower speeds, which minimizes friction and heat generation. As I know, the design of the cold saw allows for efficient chip evacuation, ensuring that the heat is carried away from the cutting area.

Why is it called a band saw?

According to my research, ‘band’ refers to the blade’s shape resembling a band or loop. A band saw is a cutting tool named for the continuous band-like blade used to cut through materials.

Its blade is a long, narrow strip of steel welded together at the ends to form a loop. This loop is then mounted on wheels, allowing it to rotate continuously while cutting through the material.

This design allows the band saw to make precise and intricate cuts in various materials, making it a versatile tool in woodworking industries.

Deciding Between Cold Saw and Band Saw for Your Woodworking Projects

After examining the differences between cold saw and band saw for projects involving wood, it’s clear that both tools have their unique advantages.

While both tools play integral roles in metalworking and carpentry, the amount of burr on the cuts stands out as a defining factor. The clean, smooth cuts produced by cold saws make them indispensable for applications where precision and finishing quality are paramount.

On the other hand, band saws, while delivering good quality cuts, may introduce a slightly rougher edge. However, the band saw provides versatility and can handle larger workpieces.

In my opinion, the choice between the two depends on the specific requirements of the project at hand.

- Powerful 2 HP Motor for Precision Cuts

- Flood Coolant System Extends Blade Life

- Adjustable Material Depth Stop for Consistency

- Heavy-Duty Cast Iron Frame Base

- Two-Piece Blade Guard for Easy Changes

- Powerful 3A Motor for Efficient Cuts

- Versatile 0-45° Aluminum Work Table

- Fast and Precise 2500FPM Blade

- Double Safety Switch for Security

- Effective 2-1/2″ Dust Collection

Last update on 2025-07-10 / Affiliate links / Images from Amazon Product Advertising API