Why Does My Table Saw Blade Wobble: 7 Reasons with Fixes

Table saws are invaluable tools in woodworking, capable of producing precise cuts when properly maintained. However, I believe one common challenge that woodworkers encounter is blade wobbling, which can lead to imprecise cuts, kickbacks, and safety hazards. So, identifying and fixing is necessary.

Improper alignment with the miter slot can cause the blade to wobble. A bent or damaged blade arbor can also lead to wobbling. Worn or damaged bearings on the arbor and a warped or damaged blade can contribute to blade wobble.

Here, I will discuss the reasons why table saw blades may wobble and provide solutions for addressing this issue. So tighten your tool belt and get ready to fix that wobbly table saw blade once and for maximum wooden job.

Why Does My Table Saw Blade Wobble: Reasons and Solutions

I’ve identified seven common reasons why a table saw blade may wobble, along with their corresponding solutions. Here are the reasons:

- Improper alignment with miter slot

- Bent or damaged blade arbor

- Worn or damaged bearings on the arbor

- Debris and sawdust buildup

- Warped or damaged blade

- Loose nuts and bolts

- Arbor holes out of round

Let’s see each of these reasons in detail and discover how to fix them.

No 01: Improper Alignment with Miter Slot

When your table saw blade is not aligned correctly with the saw’s miter slot, it can result in wobbling. This misalignment may cause the blade to veer off course, leading to irregular and imprecise cuts. Visual symptoms include cuts that are not straight or parallel to the miter slot.

To verify the alignment, adjust the saw’s alignment settings and use a miter gauge to check if the blade runs parallel to the slot. Start by loosening the bolts that secure the blade to the arbor.

Then, use a combination square or a reliable measuring tool to measure the distance between the blade and the miter slot at the front and back edges. Make adjustments as necessary until the blade is parallel to the slot. I believe this will help eliminate wobbling and ensure precise and straight cuts.

No 02: Bent or Damaged Blade Arbor

Addressing a bent or damaged blade arbor is crucial when eliminating wobbling in your table saw blade. The blade arbor is responsible for holding the blade in place, and any damage or bending can lead to misalignment and wobbling.

Visually, you may notice that the arbor shaft appears bent or that the blade doesn’t sit flush against it.

To solve this issue, it’s necessary to replace the bent or damaged arbor with a new one. This will ensure proper alignment and eliminate any wobbling in your table saw blade.

No 03: Worn or Damaged Bearings on the Arbor

The bearings on the arbor play a critical role in holding the main shaft securely and allowing smooth blade rotation. When these bearings become worn or damaged, they can no longer provide the necessary support, resulting in blade wobbling.

Signs of worn or damaged bearings include abnormal noises during operation and visible wear or damage to the bearings, causing the saw to smoke.

According to my knowledge, carefully examine the bearings for any signs of wear or damage. If necessary, replace them with new bearings to ensure a stable and smooth blade rotation to ensure longevity.

No 04: Debris and Sawdust Buildup

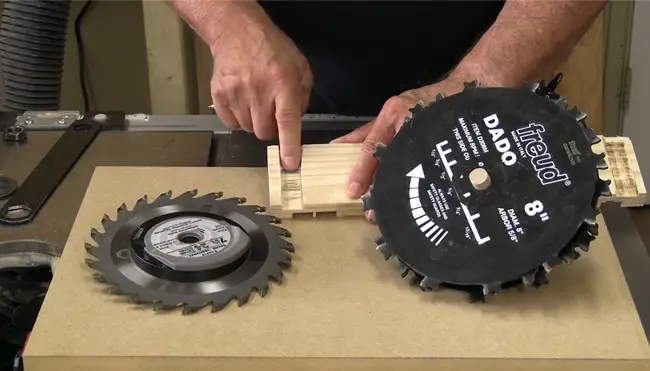

When debris and sawdust accumulate between the blade and the arbor, it can cause your table or radial arm saw blade to wobble. This buildup can disrupt the smooth rotation of the blade, resulting in a misaligned cut and potential injury.

In my opinion, it’s important to regularly clean the arbor, arbor washers, blades, and nuts to remove accumulated debris and sawdust. Use a brush or compressed air to dislodge the buildup, making sure to reach all the tight spaces.

No 05: Warped or Damaged Blade

A warped or damaged reverse-threaded table saw blade can cause wobbling and should be replaced immediately.

When it becomes warped or damaged, the blade can no longer spin smoothly, causing uneven cuts and safety hazards. Visually inspect the blade for bends or irregularities in its shape. If you notice any damage, it’s crucial to replace the blade promptly.

Using a warped or damaged blade can lead to further issues, such as inaccurate cuts, kickback, and increased wear on the saw’s motor.

As far as I know, the way to fix it, purchase a new, straight blade compatible with your table saw model. Installing a new blade will restore stability and ensure precise, accurate and safe cuts.

No 06: Loose Nuts and Bolts

Tightening loose nuts and bolts is essential to address the issue of blade wobbling in a table saw. When the nuts and bolts that hold the blade in place become loose, it can lead to vibrations that cause the blade to wobble. This can result in inaccurate cuts and potential safety hazards.

To fix this problem, carefully inspect the table saw’s assembly and identify any visibly loose nuts and bolts. I recommend using the appropriate tools, such as a wrench or socket set, to tighten them securely. Also, I suggest regularly checking and tightening all nuts and bolts of the blade to prevent vibration-related wobbling.

No 07: Arbor Holes Out of Round

Another common reason arbor holes are out of round is wear and tear over time. This can happen due to regular use, improper storage, or mishandling. Another reason could be manufacturing defects, where the arbor holes weren’t machined properly.

To solve this issue, carefully inspect the arbor holes for any signs of deformation or damage. If any irregularities are found, replace the blade and washers with new ones with perfectly round arbor holes, ensuring proper alignment and reducing blade wobble.

How do you fix a wobbly circular saw blade?

According to my research, fixing a wobbly saw blade involves properly aligning and tightening all bolts and screws securing the blade to the saw.

- Start by checking that all the bolts and screws are securely fastened. Use a wrench or a screwdriver to tighten them as needed.

- If the blade continues to wobble, it may be misaligned with the saw. To adjust the alignment, unplug the saw and raise the blade to its highest position.

- Loosen the arbor nut and adjust the blade until it’s perpendicular to the base plate. Once the blade is properly aligned, tighten the arbor nut securely.

- I strongly suggest ensuring the blade is tightened and aligned properly for a safe and accurate cutting experience.

How can I measure the wobble of my table saw blade accurately?

When measuring the wobble of your table saw blade, a dial indicator or digital angle gauge is the tool you need. This precision instrument allows you to measure the variation in blade movement with great accuracy.

- To begin, mount the dial indicator on a stable surface near the blade, ensuring that the indicator’s contact point is positioned against the side of the blade.

- Next, manually rotate the blade and observe the dial indicator’s reading. The reading will display the amount of wobble present in the blade’s movement.

- As far as I know, the variation should be less than 0.002 inches for optimal performance.

Is it safe to use a table saw with a slightly wobbling blade?

Using a table saw with a slightly wobbling blade can pose safety risks and compromise the accuracy of your cuts. Even a small amount of wobble can lead to significant issues.

Firstly, it can result in inaccurate cuts, affecting the quality and precision of your woodworking projects.

Additionally, a wobbling blade increases the chances of kickback, which occurs when the workpiece is forcefully thrown back at the operator. This can cause serious injuries and damage to the workpiece.

Moreover, a wobbling blade can also put additional strain on the motor and other components of the table saw, potentially leading to mechanical failures.

Should I lubricate the arbor bearings to reduce wobbling?

The arbor bearings play a crucial role in supporting and stabilizing the blade, allowing it to rotate smoothly and accurately. Over time, these bearings can become dry or clogged with debris, leading to increased friction, overheated damage and potential wobbling.

By applying lubrication to the arbor bearings, you can minimize friction and promote better rotation. However, it’s important to note that lubrication alone may not eliminate blade wobbling. Other factors, such as blade quality, alignment, and tightening of the arbor nut, should also be considered.

Master the Art of Table Saw Maintenance

The wobbling of a table saw blade is a common issue caused by various factors. I believe woodworkers can maintain their saws and produce high-quality work by understanding the reasons for blade wobbling and the solutions.

By regularly inspecting, cleaning, and aligning your table saw, you can create a safer and more efficient working environment. As a result, this leads to improved woodworking outcomes and greater satisfaction with your projects.

Keep in mind that a stable saw blade is the key to achieving accurate and professional results in your woodworking endeavors.