Which Way Do Circular Saw Blades Go When They’re Working?

Understanding the correct rotation direction of circular saw blades is fundamental to unlocking their full potential in woodworking and construction applications. Blade rotation serves more than just technical purposes, including optimizing cutting efficiency and ensuring operator safety.

According to my findings, circular saw blades cut upwards clockwise. When correctly installed, the teeth point upward, as circular saws typically cut on the upward stroke. This orientation ensures efficient cutting and enhances safety during woodworking operations.

Here, I’ll provide a closer look at the reasons behind this rule. So, let’s dive into the details and find out the correct rotation direction for your circular saw blade.

Why Circular Saw Run Upwards Clockwise: 8 Reasons

When cutting wood, I think knowing how the blade rotates is important. That’s why I listed 8 reasons why the saw blade should rotate upwards clockwise during wood cutting.

- Optimal cutting efficiency

- Safety and control

- Effective material ejection

- Preventing incorrect cuts

- Minimizing kickback

- Enhanced finish and surface quality

- Versatility in cutting applications

- Reduced operator fatigue

No 01: Optimal Cutting Efficiency

I know that circular saw blades must be properly positioned with the teeth pointing upward as they enter wood to achieve optimal cutting efficiency. This specific orientation allows the teeth to engage with the wood fibers most effectively.

The upward-facing teeth cut through the wood fibers as the blade spins, creating clean and precise cuts. This design ensures that the blade encounters minimal resistance during cutting, allowing for faster and more efficient cutting.

Additionally, the teeth pointing upward prevent the wood from splintering or tearing, resulting in a smoother finished product.

No 02: Safety and Control

The upward rotation of the blade creates a downward force on the wood, securely holding it against the saw’s base. This prevents the saw from being lifted or thrown up during cutting, especially when encountering hard spots in the material.

By maintaining a firm grip on the wood, the upward spin of the blade enhances overall stability, allowing for more precise and controlled cuts.

No 03: Effective Material Ejection

As a woodworker enthusiast, I found that circular saw blades with teeth pointing upward ensure effective material ejection and a clean work environment. When the teeth are oriented this way, they cut through the wood from bottom to top, allowing the sawdust and chips to be efficiently ejected through a dust port.

This prevents the accumulation of debris that could hinder the cutting process and compromise the accuracy of the cuts.

Effective material ejection is crucial for a cleaner work area and improved visibility during the cutting process. By keeping the cutting area clear, you can better control the saw and reduce the risk of accidents.

Additionally, proper material ejection helps prolong the saw blade’s lifespan by preventing debris buildup that can cause premature wear and tear.

No 04: Preventing Incorrect Cuts

You can achieve precise and accurate cuts by ensuring the teeth face the right direction. This is especially important when working with delicate or expensive materials, as any mistakes can result in wasted materials and additional costs.

Installing the blade correctly, with the teeth pointing upward, allows for a smooth and efficient cutting process. It ensures that the circular saw blade cuts from the bottom up, preventing any potential damage to the material.

No 05: Minimizing Kickback

For better cutting experiences and to minimize kickback, I believe you must correctly position circular saw blades on woodworking projects.

The upward rotation of the blade is essential in reducing the risk of kickback, which can occur when the blade binds to the material being cut. Having the teeth of the blade facing upwards prevents the wood from being lifted, preventing the saw from kicking back towards the user.

Working with larger or thicker wood may pose a higher risk of serious injuries with the circular saw due to a tendency to bind the blade.

No 06: Enhanced Finish and Surface Quality

Using circular saw blades in the correct direction is crucial for achieving an enhanced finish and surface quality on woodworking projects.

When the teeth of the blade move upward through the wood, they cut against the grain and minimize tear-out or splintering. This results in a cleaner and more polished appearance, which is especially important in projects where the aesthetics of the cut are paramount.

To achieve this, I suggest ensuring that the saw blade is installed in the correct rotation direction specified by the manufacturer. Additionally, using a blade with the appropriate number of teeth for the specific woodworking task is important.

A higher tooth count generally produces a smoother finish, while a lower tooth count is better suited for rough cuts.

No 07: Versatility in Cutting Applications

Switching between ripping, crosscutting, and making finish cuts is crucial for adapting to different wood types, sizes, and project requirements.

By choosing the correct rotation direction (upward spin), woodworkers can ensure the blade performs optimally in each cutting application. This versatility allows for precise and accurate cuts, resulting in high-quality woodworking projects.

The versatility of circular saw blades allows woodworkers to tackle any task confidently, whether they are making rough cuts or delicate finish cuts.

No 08: Reduced Operator Fatigue

As far as I know, the upward rotation of the blades plays a critical role in minimizing the operator’s strain. When the blade rotates in this direction, it helps to lift the material, creating a more controlled cutting process. This reduces the resistance the operator experiences while guiding the saw through the wood.

As a result, less effort is required to maintain contact with the material, leading to decreased fatigue during prolonged cutting sessions.

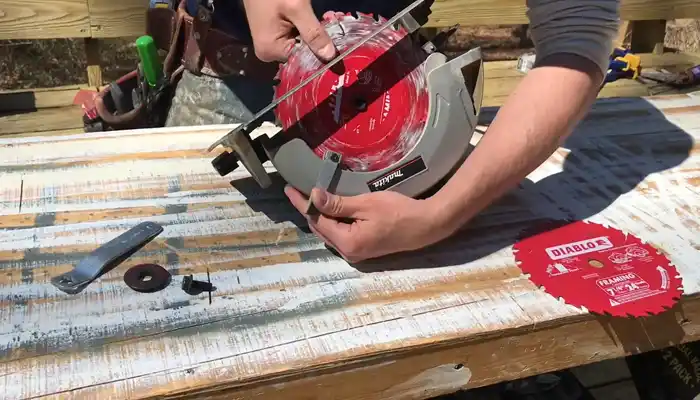

Can I install a circular saw blade in any direction?

You can use circular saw blades in any direction. However, installing the blade in the correct rotation direction is essential for optimal performance and safety.

Circular saw blades are specifically designed to cut efficiently in one direction. I believe backward blade installation produces subpar cutting performance, increased operator fatigue, and potential safety risks.

Woodworking with Proper Circular Saw Blade Rotation Direction

As you can see, the correct rotation direction for circular saw blades on woodworking projects is indeed vital. Making circular saw blades cut upwards in a clockwise direction reflects a fundamental principle in woodworking that minimizes the risk of injury.

This orientation, with teeth pointing upward, not only aligns with the natural cutting motion of circular saws. It also underscores the importance of precision and safety in every woodworking endeavor.

So, I recommend ensuring that the blade is oriented correctly for the utmost precision and efficiency in your woodworking endeavors. Don’t forget that even the finest craftsmen can be humbled by a misaligned saw blade.