What Is Through Cutting on a Table Saw? Tools and Techniques

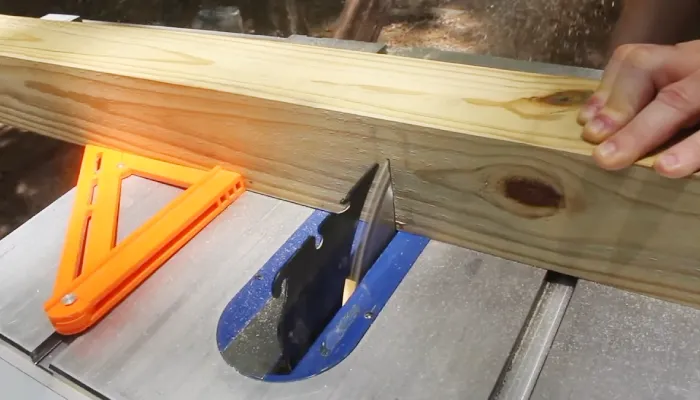

Through cutting on a table saw means cutting all the way through your wood piece, separating it into two parts with precision. You’ll use the fence to guide rip cuts or a sled for crosscuts, making sure the blade is set slightly higher than the wood thickness.

Always wear safety gear and use push sticks to protect your hands. Getting your blade sharp and aligned is key for clean cuts. Keep going to discover tips, safety measures, and practical applications that’ll improve your results.

Key Takeaways

- Through cutting on a table saw involves cutting material completely through to separate it into two pieces.

- It is commonly used for rip cuts and crosscuts to achieve precise dimensions.

- Proper alignment with the fence and blade is essential for straight, accurate cuts.

- Safety requires using push sticks and avoiding standing directly behind the blade.

- This technique is fundamental for woodworking projects like furniture building and panel making.

Through Cutting Overview

Through cutting on a table saw means making a complete cut that separates your material into two pieces. You’ll use this method primarily for rip cuts and crosscuts, aiming to divide wood or other materials into exact sizes.

This technique is one of the most versatile as it allows for cutting various types of wood and materials with precision.

To do it right, align your material carefully with the saw blade and use the fence to guide the cut, which helps maintain accuracy and control. This technique is essential for projects like furniture building or creating panels where precise dimensions matter.

For safety, it is important to avoid standing directly behind the blade and to use a push stick for smaller lumber to keep hands away from the blade during through cuts positioning during cutting.

However, you need to stay alert because through cuts can be risky if done improperly. Following proper technique and safety measures will help you achieve clean, accurate cuts every time, making your woodworking tasks more efficient and professional.

Utilizing safety accessories such as blade guards and riving knives can significantly reduce the risk of accidents.

Tools and Equipment Needed

Making accurate and safe cuts on a table saw depends heavily on having the right tools and equipment.

To perform through cutting effectively, you’ll need several key components and accessories:

- Saw Blade and Fence System – Choose a sharp, appropriate blade and an adjustable fence for consistent, straight cuts. It is essential to inspect the table saw for loose bolts and damaged parts before use to ensure safety.

- Safety Gear – Always wear safety glasses and hearing protection. Use blade guards and push sticks to keep your hands safe.

- Material Handling Tools – Use miter gauges or crosscut sleds to guide your workpiece precisely through the blade. Featherboards help maintain steady pressure against the fence.

- Table Saw Type – Depending on your work, select a stationary or portable saw with suitable motor power and stability for the job. For example, a portable table saw may feature a 15 Amp motor, which balances power and mobility effectively.

Techniques for Effective Through Cutting

When you want clean, accurate cuts on your table saw, mastering key techniques makes all the difference.

Always align your workpiece firmly against the rip fence for rip cuts or use a crosscut sled for crosscuts to maintain precision. Set your blade at a 90-degree angle unless a bevel cut is needed.

Remember to raise the blade slightly above the wood thickness to ensure a clean cut and reduce material binding, as recommended for safe operation with the blade height adjustment. Using a high-quality T-Glide Fence System can greatly improve cutting accuracy and stability.

Feed the material steadily and smoothly, adjusting speed especially with harder woods to prevent kickback. Keep your blade sharp and regularly calibrate the saw to guarantee fence and blade alignment.

Support your material well to avoid uneven cuts. Double-check measurements before cutting and inspect the finished cut for any adjustments.

Safety Measures and Precautions

Although table saws are powerful tools that can handle a variety of cutting tasks, you must prioritize safety measures to prevent accidents. Before cutting, always inspect your wood for nails or knots and confirm the fence aligns perfectly with the blade to reduce kickback risk.

Keep guards and anti-kickback devices in place and functioning. Wear safety gear like glasses, ear protection, and a dust mask.

Follow these key precautions:

- Use a push stick for narrow cuts to keep hands safe.

- Stand clear of the blade’s kickback zone.

- Keep your work area clean and free of debris.

- Never reach for materials near the blade until it stops completely.

Stay alert and maintain your saw regularly to confirm safe, precise cuts every time. Avoid wearing gloves while operating a table saw to maintain optimal control and precision.

Common Applications and Projects

When you use through cutting on a table saw, you can efficiently prepare parts for furniture making, ensuring each piece fits perfectly. It’s also essential for creating precise joints that hold your woodwork together securely.

Plus, this technique plays a big role in construction and cabinetry, where accurate panel cuts make all the difference. Through cutting increases efficiency in woodworking tasks, saving time and effort on complex projects.

Furniture Making Uses

Since precise cuts form the foundation of quality furniture, through cutting on a table saw plays an essential role in shaping components like shelves, tabletops, and cabinet sides.

You’ll rely on through cutting to handle large sheets of plywood or MDF and achieve uniform, accurate parts. This technique guarantees your pieces fit perfectly, boosting both function and appearance.

Using a high-quality combination blade ensures clean cross cuts and rips, which is vital for achieving professional results. However, it is important to understand that motor power can affect cutting performance, especially when working with thicker materials.

Common furniture applications where through cutting shines include:

- Cabinet construction – cutting shelves and doors to exact dimensions.

- Table making – shaping tops and legs with uniformity.

- Shelf building – creating stable, evenly sized boards.

- Panel production – preparing pieces for wardrobes or cabinets.

Wood Joinery Preparation

Wood joinery preparation demands careful through cutting on a table saw to guarantee strong, precise connections. You’ll often use through cuts for joints like half-laps, tenons, and bridles. Using proper safety equipment is essential to avoid injuries during these operations.

Start by marking cuts accurately and setting your blade height to half or full stock thickness, depending on the joint. Use a sharp crosscut blade or dado stack for clean, square cuts. For example, half-lap joints rely on cutting rabbets or dadoes to half the thickness of mating pieces for strong, long-grain glue bonds.

For half-lap joints, cut shoulders to half the thickness, then clear waste with multiple passes or a dado blade. Tenons and bridles require shoulder and cheek cuts, often with jigs for stability and repeatability.

Accessories like miter gauge extensions and tenoning jigs help maintain control. Always keep fences aligned, blades sharp, and use push sticks for safety while making through cuts for joinery.

Construction and Cabinetry

Mastering through cuts on a table saw sets the stage for practical applications in construction and cabinetry, where precision and efficiency matter. Using a table saw with proper setup and blade selection ensures clean and accurate cuts that enhance project quality.

You’ll find table saws invaluable for making accurate rip and crosscuts, essential in framing, decking, and flooring projects. In cabinetry, they enable precise dado cuts and smooth edges for seamless assembly and design flexibility.

Their speed helps you meet tight deadlines while advanced safety features keep your workspace secure. Modern table saws often come equipped with advanced safety features like automatic shut-off systems to minimize injury risks.

Here are four common applications you’ll encounter:

- Furniture making – precise cuts for durable pieces

- Deck building – exact plank sizing

- Cabinet assembly – accurate dado and edge cuts

- Trim work – clean, consistent finishing cuts

Using a table saw efficiently boosts your productivity and craftsmanship across these projects.

Tips for Best Results

When you want clean, accurate through cuts on your table saw, pay close attention to your cutting speed and feeding rate. Adjust your speed to match the material—too fast can cause binding or rough edges, too slow risks overheating the blade.

Maintain a steady, consistent feed to guarantee smooth cuts without tear-out. Set the blade height just above the material thickness to optimize cutting efficiency. Riving knives are often set just below blade height for efficiency, which helps maintain consistent cutting performance. Using a properly aligned riving knife behind the blade is essential to prevent kickback and ensure safety.

Support longer workpieces firmly to prevent sagging or vibration that could throw off your cut. Always double-check measurements before cutting to minimize waste. Remember, alignment is key—make sure your fence is parallel to the blade and your workpiece is properly secured.

Frequently Asked Questions

Can Through Cutting Damage the Table Saw Blade?

Yes, through cutting can damage your table saw blade if you’re not careful. Using a dull blade, forcing the material, or cutting dense hardwoods increases wear and risk of binding. Misaligned blades or fences also cause stress and potential damage.

To protect your blade, keep it sharp, guarantee proper alignment, and use a riving knife to maintain the kerf gap. Regular maintenance is key to avoiding blade damage during through cuts.

How Do Different Wood Types Affect Through Cutting?

Wood’s weight and weave wildly wield your work’s weariness. Dense hardwoods demand more drive and sharper blades, while softer woods slice smoothly with less strain.

Grain direction guides your glide; cutting with the grain eases effort. Moisture matters, too—wet wood slows your saw and risks ragged results. Exotic woods, rich in resin, can gum up your gear, forcing frequent blade cleaning or changes to maintain precision and protect your table saw.

What Is the Ideal Blade Speed for Through Cutting?

You want to set your blade speed based on your saw’s power and the material. Small saws (1-2 HP) work best around 3000 RPM, while more powerful models run near 4000 RPM. For a 10-inch blade, aim for 3000-3500 RPM to reach ideal tooth speed.

Softer woods can handle higher speeds, but denser materials require slower speeds to avoid burning or jamming. Adjust speed to balance clean cuts and blade longevity.

Can Through Cutting Be Done on Metal or Plastic?

You can perform through cutting on plastics with a table saw, but you need the right blade and proper speed to avoid melting or chipping.

For metal, it’s best to avoid table saws altogether since they’re not designed for that—you’ll risk blade damage and safety hazards. Instead, use specialized tools like band saws or cold saws for metal. Always wear protective gear and guarantee your equipment matches the material for safe, effective cuts.

How to Troubleshoot Common Issues During Through Cutting?

To troubleshoot common through cutting issues, first check that your fence is perfectly parallel to the blade to avoid kickback and uneven cuts.

Make sure the blade is sharp, clean, and set just 1/8 inch above the wood. Support the workpiece properly to prevent binding, and feed the material steadily without forcing it. Use push sticks and safety guards, and adjust blade alignment if cuts are angled or burning occurs.

Cut with Confidence: Safety and Precision Matter Most

So, you’ve learned that through cutting on a table saw is as simple as pushing wood through a spinning blade—too bad it’s not always that straightforward. With the right tools, techniques, and safety gear, you’ll avoid turning your project into a disaster zone.

Remember, precision and caution aren’t just suggestions; they’re your best friends. Master these, and you’ll cut through wood like a pro—without cutting through your fingers.