Is Danish Oil Food Safe: Kitchen Confidence Starts

You can use Danish Oil safely on food-contact wood surfaces, but only after it’s fully cured. This means all solvents and additives have evaporated, leaving a hard, non-toxic, and durable finish.

Until then, wet or tacky surfaces aren’t safe for direct food contact due to lingering chemicals. Proper drying times and cure are vital, plus you need to apply it carefully in thin coats.

Understanding its ingredients and best practices will help guarantee safety and performance in your kitchen.

Key Takeaways

- Danish Oil is food safe only after it is fully cured, with all solvents and additives completely evaporated.

- Wet or partially cured Danish Oil surfaces are not safe for direct food contact due to toxic solvents and additives.

- Fully cured Danish Oil forms a hard, non-toxic, and chemically inert finish suitable for food-contact surfaces.

- Avoid using Danish Oil with metallic driers or uncured varnishes for food safety concerns.

- Proper application involves multiple coats and extended drying times to ensure complete curing before food use.

What Is Danish Oil and How Does It Protect Wood?

Although you might think Danish Oil is just another wood finish, it actually combines boiled linseed oil with varnish and solvents to penetrate and protect wood deeply.

When you apply it, the oil seeps into the wood fibers, enhancing durability from within rather than merely sitting on the surface.

The varnish component adds a protective layer that resists wear and moisture, while solvents help the mixture spread evenly and dry properly.

You’ll find that Danish Oil creates a hard-wearing, satin finish that remains breathable, allowing the wood to age naturally.

However, be cautious. Until fully cured, the finish contains solvents and oils that aren’t safe for direct food contact.

Proper application and drying time are essential to guarantee a durable, protective, and safe wood surface. Danish oil’s solvent and resin content also means it can leave a faint chemical undertone even after drying.

When Is Danish Oil Considered Food Safe?

Hey there! So, when can you really think of Danish Oil as being food safe? Well, you should only consider it safe once it’s fully cured.

That means all the solvents and additives need to evaporate completely.

This curing process is super important; it ensures that the finish complies with food contact regulations and meets safety standards.

Until that happens, the oil isn’t safe for direct food contact. So, just be patient and let it cure properly!

Proper curing forms a waterproof, chemically inert film that prevents harmful substance migration, ensuring safety for food-contact surfaces.

Fully Cured Requirements

When Danish Oil fully cures, it transforms from a liquid containing solvents and additives into a hard, non-toxic finish that’s safe for food contact.

To guarantee food safety, you need to meet these fully cured requirements:

- Apply 2-3 coats evenly, allowing proper penetration and protection.

- Allow sufficient drying time, typically several days, to complete polymerization.

- Confirm all solvents and additives have evaporated and the oil has hardened fully.

- Verify the finish feels smooth and durable, with no tackiness or odor remaining.

Only after these steps can you safely use Danish Oil-treated surfaces for kitchenware, utensils, or children’s toys.

For the best results, it’s recommended to lightly sand between coats with fine grit sandpaper to ensure proper adhesion and a smooth finish.

Evaporation of Solvents

Because solvents and additives in Danish Oil evaporate during curing, the finish becomes safe for food contact only after this process completes.

When you apply Danish Oil, solvents act as carriers, helping the oil penetrate the wood. These solvents then evaporate, leaving behind a hardened, protective layer.

You need to wait until the surface is completely dry and cured. This can take several days, depending on conditions and the number of coats applied.

Until then, the finish contains volatile compounds that aren’t safe for food contact. Only after full evaporation and polymerization does the finish become non-toxic and food safe.

Proper application and curing times are essential to ensure food-grade finish safety and durability.

Food Contact Compliance

Although Danish Oil contains solvents and additives initially, it becomes food safe only after it has fully dried and cured.

When you use Danish Oil on surfaces that come in contact with food, compliance is key. Here’s when you can consider it safe:

- After the oil’s solvents and additives have completely evaporated through curing.

- When the finish meets FDA and related food contact regulations.

- Once it forms a hard, non-toxic, polymerized surface free of harmful residues.

- If applied correctly, multiple coats and sufficient drying time guarantee safety.

Until then, avoid direct food contact with the wet or partially cured surface. Proper curing transforms Danish Oil into a safe protective layer suitable for kitchenware, utensils, and children’s toys.

Always follow manufacturer instructions to guarantee compliance and safety. Environmental factors like temperature and humidity significantly affect the drying and curing times of oils such as Danish Oil, impacting when the finish becomes food safe.

How to Apply Danish Oil for Food-Safe Kitchen Use?

Before you dive into applying Danish Oil, it’s super important to ensure that your wood surface is clean, dry, and sanded smooth. This really helps with absorption!

So, take your time with that preparation. Now, when you start applying the oil, aim for 2-3 thin coats. It’s crucial to let each coat fully dry and cure.

This step guarantees that you’ll end up with a hard, food-safe finish. Just a friendly reminder: the oil is only safe for kitchen use once it’s completely cured.

For enhanced protection and durability, consider using a finish with food-safe properties recommended for kitchen surfaces.

Proper Surface Preparation

Start by sanding your wood surface smoothly and evenly to guarantee peak Danish Oil absorption and a flawless finish.

Proper preparation makes certain the oil penetrates deeply, creating a durable, food-safe coating.

Follow these steps:

- Use progressively finer grit sandpaper, starting at 120 and finishing at 220 grit, to remove imperfections and open the wood pores.

- Clean the surface thoroughly with a tack cloth to eliminate dust and debris that could interfere with oil absorption.

- Avoid using water or solvents before oiling, as moisture can hinder drying and curing.

- Inspect the wood for cracks or rough spots and sand or fill as needed to achieve an even surface.

Taking time here prevents uneven finishes and helps you achieve a safe, long-lasting kitchen surface.

For best results, applying multiple coats with adequate drying time between each enhances the food-safe finish and durability.

Application And Curing

Apply Danish Oil carefully in thin, even coats to guarantee thorough penetration and a durable, food-safe finish. Use a clean cloth or brush to spread the oil evenly, allowing it to soak into the wood for 15-30 minutes.

Afterward, wipe off any excess to prevent a sticky surface. Repeat this process for 2-3 coats, guaranteeing each layer dries completely before applying the next.

Curing time is essential; let the oil dry for at least 24-48 hours per coat in a well-ventilated area.

Only when fully cured does Danish Oil become non-toxic and safe for food contact. Avoid rushing the curing process, as insufficient drying compromises food safety and finish durability. Proper application and curing guarantee your kitchen surfaces stay protected and safe.

For optimal results, consider reapplying the oil every 3–6 months as part of regular maintenance and resealing to preserve the wood’s condition and food safety.

Safe Uses of Danish Oil on Food-Contact Surfaces

When you use Danish Oil on food-contact surfaces, you must make certain it’s fully dried and cured to guarantee safety. Only then does it form a non-toxic, durable finish suitable for kitchen items.

You can safely apply Danish Oil to:

- Kitchen worktops and butcher blocks for a protective, food-safe surface.

- Serving platters, salad bowls, and cutting boards to enhance wood grain and resist moisture.

- Utensils and wooden cutlery that come into direct contact with food.

- Children’s toys and pet-contact surfaces once the oil is properly cured.

Avoid using Danish Oil in its liquid form on these surfaces since it contains solvents harmful if ingested. Fully cured Danish Oil complies with food safety standards, making it reliable when you follow application and curing guidelines carefully.

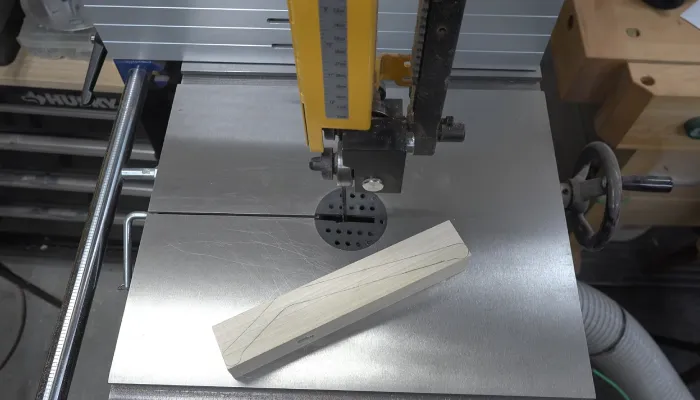

For best results, ensure proper dust collection efficiency in your workshop to maintain a clean environment during finishing.

Which Ingredients in Danish Oil Matter for Food Safety?

Although Danish Oil formulations vary, the key ingredients that affect food safety include boiled linseed oil, varnishes, and solvents. These must fully cure and evaporate before the finish becomes non-toxic.

You need to make certain that solvents and any metallic driers have completely dissipated, as their presence can pose health risks. Polymerized linseed oil without solvents is often safer.

Here’s a quick look at the main components and their food safety implications:

| Ingredient | Role | Food Safety Note |

|---|---|---|

| Boiled Linseed Oil | Penetrates and seals wood | Safe once fully cured |

| Varnishes | Adds protective layer | Must be non-toxic and cured |

| Solvents | Thins oil for application | Evaporate; avoid if not fully dried |

| Metallic Driers | Speeds curing | Avoid if possible for purity |

| Resins | Enhances durability | Ensure FDA-compliant formulations |

It is critical to allow the finish to reach full polymerization to ensure all harmful components have cured and the surface is safe for food contact.

Best Alternatives to Danish Oil for Heavy-Duty Surfaces

Consider switching to specialized oils designed for heavy-duty surfaces if you need more durability than Danish Oil provides.

While Danish Oil offers food-safe protection once cured, it may lack the resilience required for intense wear.

Here are four alternatives to ponder:

- Tung Oil: Penetrates deeply, offers superior water resistance, and cures to a tough, food-safe finish.

- Pure Linseed Oil (polymerized): Provides natural protection with a durable, non-toxic surface.

- Food-Safe Hard Wax Oils: Combine oils and waxes for enhanced surface hardness and water resistance.

- Worktop Oil: Specifically formulated for kitchen surfaces, offering robust durability and food safety.

Choose carefully based on your surface use and maintenance preferences to guarantee safety and longevity.

Frequently Asked Questions

Can Danish Oil Cause Allergic Reactions in Sensitive Individuals?

Yes, Danish Oil can cause allergic reactions in sensitive individuals, especially during application when it’s still wet.

You might experience skin irritation or respiratory issues from solvents or additives before it fully cures. Once dried and cured, it’s generally safe and non-toxic.

To minimize risk, you should wear gloves, work in a well-ventilated area, and avoid prolonged skin contact. If you have a history of allergies, test on a small area first.

How Long Does Danish Oil Take to Fully Cure for Food Safety?

Danish Oil typically takes about 7 days to fully cure for food safety, ensuring solvents and additives evaporate completely.

You’ll want to apply 2-3 coats, allowing each layer to dry thoroughly, usually 24 hours per coat, before use.

This curing period guarantees a hard, non-toxic finish safe for kitchenware.

Rushing this process risks exposure to uncured chemicals, so patience is key to achieving a safe, durable surface.

Is Danish Oil Safe for Use on Children’s Wooden Toys?

Yes, you can safely use Danish Oil on children’s wooden toys once it’s fully dried and cured.

The oil becomes non-toxic and food safe after curing, meeting safety standards for pet and child contact.

Just make sure you apply 2-3 coats and allow complete polymerization before letting kids play with the toys.

Avoid using uncured oil, as it contains solvents and additives that aren’t safe for direct contact.

Can Danish Oil Be Used on Pet Bowls and Feeding Stations?

Yes, you can use Danish Oil on pet bowls and feeding stations, but only once it’s fully dried and cured.

The cured finish is non-toxic and safe for your pet’s contact, meeting food safety standards.

Just make certain to apply multiple coats and allow complete curing to avoid any solvent residues.

This guarantees a durable, safe surface your pets can lick or eat from without risk.

What Are the Environmental Impacts of Using Danish Oil?

You should know Danish Oil’s environmental impact includes solvent evaporation during curing, contributing to VOC emissions.

Some formulations contain metallic driers and resins, which may affect biodegradability.

However, premium versions with 100% polymerized linseed oil avoid solvents and toxins, reducing harm.

It’s best to use it sparingly and ensure proper ventilation.

Dispose of rags carefully to prevent spontaneous combustion, minimizing fire risk and environmental damage.

Hardened Protection or Hidden Risk? The Danish Oil Verdict

Danish oil can be food safe, but only if it’s fully cured and free from harmful additives. Think of it like a shield that needs time to harden before it’s truly protective.

You should avoid using it on surfaces with heavy wear or constant moisture. Always check the ingredients and curing time to keep your kitchen safe. When in doubt, consider safer, purpose-made finishes for food-contact surfaces to protect both your wood and your health.