How to Measure Bandsaw Blade Width: 3 Key Steps to Follow

Accurate bandsaw blade measurement is essential for safe, optimal bandsaw operation. Measuring bandsaw blades ensures quality results while keeping your working element safe and ensuring correct tension and material cutouts. But how exactly do you measure it?

Well, you can use a digital caliper or ruler to measure the bandsaw blade width accurately. Choosing the right blade width enhances machine performance, versatility in cutting tasks, and the blade’s lifespan.

Get ready to unlock the secrets because I will unravel the steps to measure bandsaw blade width with utmost accuracy in this discussion. So, tighten your grip on that tape measure and prepare to uncover the secrets of the bandsaw blade width measurement.

How to Measure Bandsaw Blade Width: Steps to Follow

To help you measure, I’ve listed three simple steps to measure your bandsaw blade’s width accurately.

- Gather the necessary tools

- Select the point of measurement

- Utilize the digital caliper for fine measurement

Step 1: Gather the Necessary Tools

Before measuring the bandsaw blade width, I suggest a handy digital caliper for accurate and precise measurements. This tool is essential for obtaining reliable results.

With a digital caliper, you can achieve accurate readings of the blade width, ensuring that your measurements are precise. It’s crucial to have the right equipment to ensure the accuracy of your measurements.

A digital caliper offers the advantage of providing digital readings, allowing for easier interpretation and more precise measurements.

Step 2: Select the Point of Measurement

Start by locating the furthest point of the teeth on the bandsaw blade, as this will serve as the reference point for measuring the width. Focus on the teeth, not the bottom of the gullet.

Proper alignment is crucial for accurate measurements, so the blade is positioned correctly. Aligning the blade properly will help you obtain precise measurements.

By selecting the furthest point of the teeth as the reference point, you can accurately measure the bandsaw blade’s width. This ensures that you have the correct measurements for any adjustments or replacements that may be needed.

Step 3: Utilize the Digital Caliper for Fine Measurement

Now that you have selected the furthest point of the teeth as your reference point, it’s time to utilize the digital caliper to measure the bandsaw blade width accurately.

The digital caliper is a precision instrument that will accurately measure the blade width. Simply place the caliper jaws on either side of the blade, ensuring they’re perpendicular to its edge. Gently close the jaws until they make contact with the blade.

The caliper should register the exact width of the blade, providing you with a precise measurement. For example, if your bandsaw blade has a five-eighths of an inch width, the caliper should display this measurement. The digital caliper is an essential tool for accurately measuring your bandsaw blade width.

Why Should You Measure Bandsaw Blade Width?

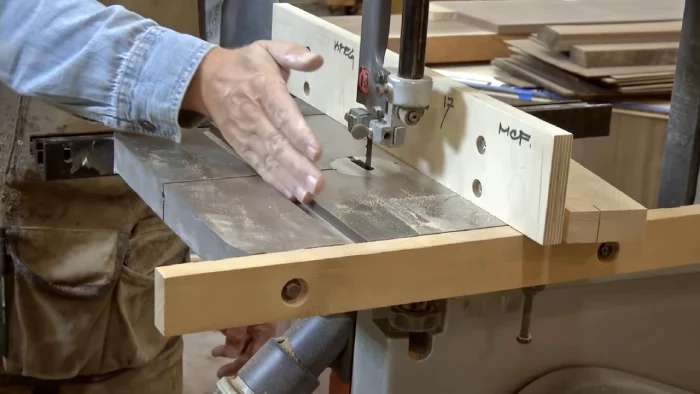

In my thoughtful analysis, a bandsaw is a stalwart tool in the world of woodworking, and measuring the width of your bandsaw blade is crucial for several reasons:

1. Accuracy in Cuts

To achieve precise and accurate cuts on your bandsaw, make sure you measure the width of your blade carefully. The width of your bandsaw blade directly affects the accuracy of your cuts.

By measuring the blade width accurately, you ensure it aligns perfectly with the intended cutting path. This alignment minimizes deviations and allows for clean, straight lines in your cuts.

2. Consistent Curve Cutting

For woodworkers seeking consistent and precise curve cutting, accurately measuring the width of the blade is paramount. The width of the blade plays a crucial role in easily navigating curves.

By measuring from the furthest point of the teeth, you ensure that your blade can handle tight curves without compromising the quality of your cuts. Wider blades provide more beam strength, which promotes stability during curved cuts.

This added stability allows for consistent and precise shaping, reducing the risk of errors and ensuring a smooth and accurate finish.

3. Optimal Machine Performance

From my vantage point, achieving optimal machine performance with your bandsaw requires careful measurement of the blade width. Following the manufacturer guidelines for acceptable minimum and maximum blade widths is essential.

Using the recommended blade width, you ensure your machine operates at its best, preventing strain on the motor and other components.

When the blade width matches the specifications, it contributes to your bandsaw’s overall efficiency and longevity. Not only does this promote smoother and more accurate cuts, but it also reduces the risk of blade damage and premature wear.

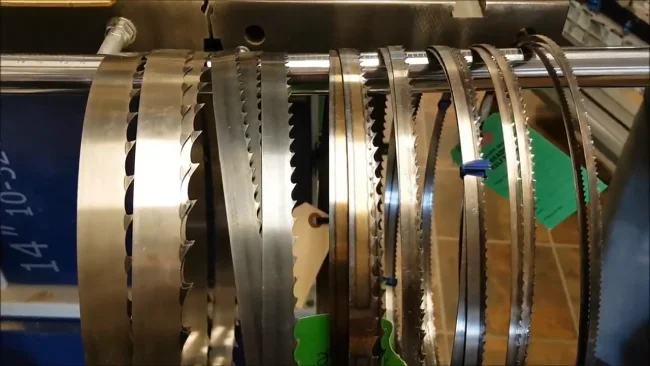

4. Versatility in Cutting Tasks

Measuring your bandsaw blade width allows you to determine the optimal tool for each cutting task, enhancing the versatility of your bandsaw. Different projects require different blade widths; by measuring the width, you can choose the right blade for the job.

Wider blades are ideal for straight cuts, providing enhanced beam strength and allowing for more precise and stable cuts. Conversely, narrower blades excel in intricate work, delivering smoother finishes and allowing for more intricate and detailed cuts.

5. Precision in Contour Cuts

Wondering why measuring bandsaw blade width is essential for achieving precision in contour cuts? Well, it all comes down to accuracy. You need a bandsaw blade that fits snugly into the desired path when cutting intricate contours.

A well-measured blade width ensures that your cuts stay true to the intended design without any deviations or errors. Imagine trying to create a delicate curve or a detailed pattern, only to have the blade wander off course due to an ill-fitting width.

6. Material Optimization

To optimize material usage, accurately measuring the saw blade width is essential. With the right blade width, you can minimize waste and make each cut more efficient, resulting in more usable material. This is especially important when working with expensive or limited resources.

By accurately measuring the bandsaw blade width, you can ensure that you’re making the most out of each piece of material, reducing the amount of scrap or leftover pieces. This not only saves you money by maximizing material utilization, but it also helps to reduce environmental impact by minimizing waste.

7. Enhanced Blade Lifespan

Accurately measuring the bandsaw blade width contributes to an enhanced blade lifespan and optimal cutting performance. Using the correct blade width, as the manufacturer recommends, is crucial for ensuring the longevity of the blade.

When the blade width is incorrect, it can result in premature wear and tear, leading to decreased cutting performance and the need for more frequent replacements. By measuring the blade width accurately, you can minimize the stress on the blade, allowing it to last longer.

This not only saves you money on frequent blade replacements but also ensures that you get consistent and efficient cutting results.

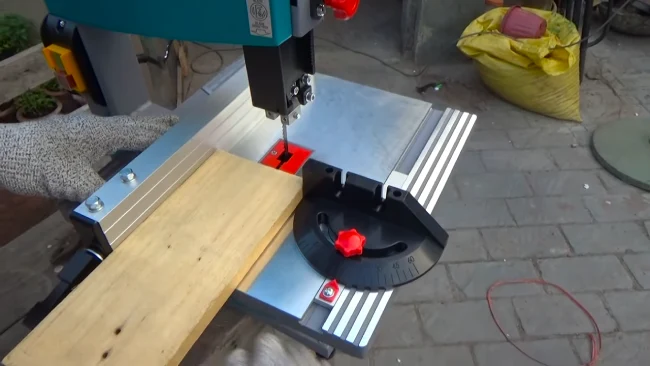

8. Efficient Resawing

For woodworkers engaged in resawing, accurately measuring the bandsaw blade width is crucial for achieving efficient and precise results. Resawing involves cutting a board into thinner sections, and the blade width plays a significant role in determining the quality of the cuts.

By measuring the blade width correctly, you can ensure that your bandsaw is equipped to handle the resawing task effectively. A correctly sized blade will deliver smooth and uniform results without compromising on the thickness of the cut sections.

If the blade is too wide, it can cause excessive waste and strain on the motor. On the other hand, a blade that’s too narrow may result in uneven cuts and a slower cutting process.

Does bandsaw blade width matter?

The width of a bandsaw blade can significantly impact its performance and the quality of your cuts. When dealing with bandsaw blades, size matters. The width of the blade affects the stability, flexibility, and accuracy of the cuts you make.

A wider blade provides more stability, reducing the chances of blade deflection during cutting. This is particularly important when resawing or making long, straight cuts. A wider blade also offers more teeth, resulting in a smoother cut and less chance of chip-out.

What are wider band saw blades mainly used for?

Wider bandsaw blades excel in applications requiring stability and a fast feed rate, making them ideal for high-horsepower sawmills.

These blades are mainly used for heavy-duty cutting tasks, such as resawing large logs or slicing thick boards. The width of the blade provides added rigidity, allowing for straighter and more precise cuts.

With their increased surface area, wider blades can withstand higher feed rates without compromising stability. This makes them perfect for cutting through dense and hard materials like hardwoods or frozen lumber.

The wider blade also helps dissipate heat more efficiently, reducing the risk of the blade overheating and extending its lifespan.

Know the Impact of Bandsaw Blade Width on Your Project’s Success

So, now you know how to measure bandsaw blade width. Woodworking and metalworking projects require precision measurements to ensure perfect cuts. But let’s be real here, does it matter? I mean, who cares about the width of a bandsaw blade? It’s just a tool, right?

Well, think again. The width of a bandsaw blade plays a crucial role in determining its performance and the types of cuts it can make. Wrong blade width can cause damage and compromise quality. Ensure your bandsaw blade is accurately measured before cutting to prevent these setbacks.

So, next time you choose a bandsaw blade, don’t underestimate the importance of its width. You might just be cutting yourself short.