How Long Should a Bandsaw Blade Last: 7 Influencing Factors

Having a long-lasting bandsaw blade helps you save time, money, and effort in the long run for your woodworking projects. But how long does a bandsaw blade generally last to provide optimal performance?

I researched this topic and found that the lifespan of a bandsaw blade varies widely based on several factors. Operational parameters, material compatibility, and proper maintenance practices all contribute to the overall longevity of your bandsaw blade.

Based on the real user’s opinion, a bandsaw blade typically lasts six months to several years. I will discuss all the factors that affect a bandsaw blade’s lifespan to assist you in getting the most out of your blade.

What Are the Factors That Affect the Lifespan of a Bandsaw Blade?

Several key factors can affect the lifespan of a bandsaw blade, such as:

- Material being cut

- Blade quality

- Blade teeth configuration

- Blade tension and alignment

- Cutting speed and feed rate

- Coolant/Lubrication

- Maintenance practices

1. Material Being Cut

The material being cut is one factor that affects the lifespan of a bandsaw blade. Bandsaw blades are designed for specific materials, and using them for unintended materials can significantly reduce their lifespan.

The hardness of the material plays a significant role in blade wear. Harder materials can accelerate blade wear, leading to a shorter lifespan.

Also, the presence of obstacles like nails can also cause premature blade wear and damage. Cutting synthetic or composite materials with abrasive ingredients can further contribute to blade wear, reducing its lifespan.

2. Blade Quality

Blade quality is another factor contributing to a bandsaw blade’s longevity. Investing in high-quality bandsaw blades made from durable materials is key to extending the blade’s lifespan. High-quality blades, when properly cared for, can last over a year.

On the other hand, blades of poor quality or improper use may experience a significantly shortened lifespan. The quality of the blade is determined by the materials used in its construction.

Blades made from high-quality materials are designed to withstand the rigors of cutting and are less likely to break or wear out quickly. They’re also more heat-resistant, which can cause blade dullness and degradation.

3. Blade Teeth Configuration

Blade teeth configuration is also a crucial factor that can influence the lifespan of a bandsaw blade. The tooth configuration, including pitch and design, determines the blade’s suitability for specific tasks.

Different tooth configurations are available, such as regular, skip, and hook. Regular tooth configuration is ideal for general-purpose cutting, while skip tooth configuration is used for cutting softer materials, as it provides increased chip clearance.

Meanwhile, the hook tooth configuration is designed for cutting harder materials, as it offers aggressive cutting action. Choosing the right tooth configuration for the intended job is essential to maximize the blade’s lifespan.

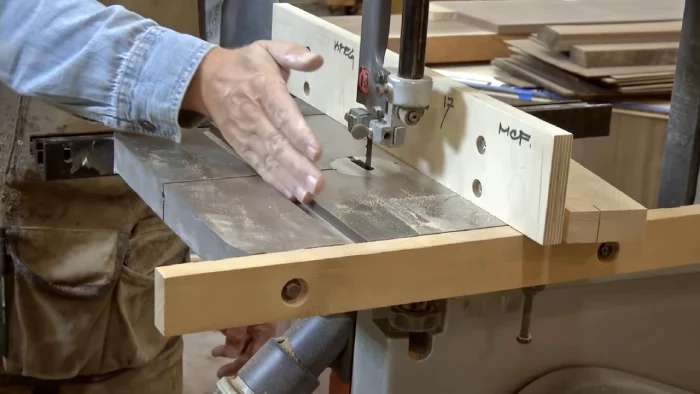

4. Blade Tension and Alignment

Blade tension and alignment greatly impact the lifespan of a bandsaw blade, ensuring optimal performance and longevity. Operating the blade at the correct tension is crucial for its functionality and durability.

When the tension is too loose, the blade can wander and become misaligned, causing it to wear unevenly and prematurely. Conversely, excessive tension can lead to blade distortion and an increased risk of breakage.

Proper alignment is equally important as it ensures that the blade tracks correctly during operation. Misalignment can result in excessive friction, heat, and wear on the blade, reducing its lifespan.

Regularly checking and adjusting the tension and alignment of the bandsaw blade is essential for maximizing its lifespan and maintaining efficient cutting performance.

5. Cutting Speed and Feed Rate

Cutting speed and feed rate play a significant role in determining the lifespan of a bandsaw blade. Adhering to specified feed rates is crucial, as exceeding them can accelerate blade wear.

When the cutting speed is too slow, the blade can become dull and overworked, leading to premature failure. On the other hand, if the cutting speed is too fast, it can cause excessive heat and friction, reducing the blade’s lifespan.

Similarly, the feed rate, or how fast the material is fed into the blade, should be controlled to prevent excessive stress on the teeth.

6. Coolant/Lubrication

Applying proper lubrication or coolant can assist in extending the lifespan of a bandsaw blade and ensuring optimal cutting performance.

When operating a bandsaw, use lubricant or coolant to reduce heat and keep the blade from dulling. This is particularly crucial when cutting materials that generate significant heat during the cutting process.

By using lubrication or coolant, the heat is effectively dissipated, allowing the blade to remain in optimal condition for a longer period. The blade can become overheated without proper lubrication, leading to premature dulling and reduced cutting performance.

Therefore, you need to ensure that the bandsaw blade is always adequately lubricated or cooled to maximize its lifespan and maintain its cutting efficiency.

7. Maintenance Practices

Proper maintenance practices play a crucial role in ensuring the longevity of a bandsaw blade. Loosening the tension after each use helps to prevent stress on the blade, reducing the risk of premature wear or breakage.

Cleaning the bandsaw blade properly after each use can help remove debris and buildup that can affect the blade’s performance. Also, storing the blade properly, such as hanging it vertically or using a blade storage rack, prevents damage and warping.

Regular maintenance, including routine inspections and minor repairs, ensures that any issues are addressed promptly, preventing further damage or deterioration.

It’s also important to know when to invest in a new blade versus attempting repairs, as using a worn or damaged blade can compromise both cutting performance and safety.

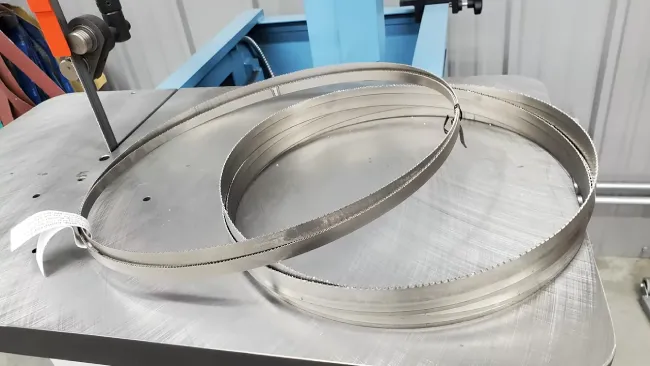

What is the correct method for storing a bandsaw blade to ensure its long-term durability?

For long-term durability, ensure your bandsaw blade remains in optimal condition by properly storing it. One effective method is to fold the bandsaw blades into loops and secure them with blade ties or rubber bands. This prevents tangling and helps maintain their shape.

Another option is to use a dedicated blade storage box, which keeps the blades organized and protected from potential damage.

If space is a concern, you can install wall-mounted brackets or a blade rack for vertical storage. This reduces the risk of harm and makes efficient use of space.

Regardless of the chosen storage method, storing your bandsaw blades in a cool, dry environment is crucial to prevent rust and corrosion.

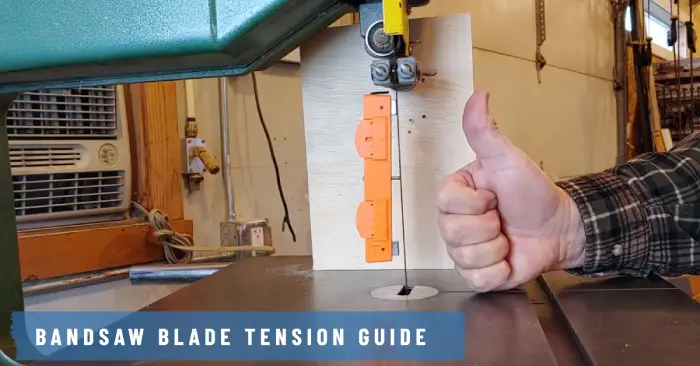

What is the appropriate blade tension for a bandsaw blade to promote long-lasting performance?

The bandsaw blade tension is typically measured in PSI (pounds per square inch) and can range from 15,000 to 30,000 psi for most bandsaw blades. However, you need to consult the manufacturer’s recommendations for your specific bandsaw model, as the ideal tension can vary.

Incorrect blade tension, whether too high or too low, can lead to premature wear and negatively impact the overall performance and lifespan of the bandsaw blade.

Properly Use and Maintain Your Bandsaw Blade for Enhanced Performance and Longevity

It is now clear that the lifespan of a bandsaw blade is a dynamic interplay of various factors. From the material being cut to blade quality, teeth configuration, tension, and maintenance practices, each aspect that I’ve shared with you contributes significantly to the blade’s longevity and performance.

Proper understanding and meticulous attention to these factors will help you maximize your bandsaw blade’s lifespan.

Also, you have to prioritize bandsaw injury prevention and safety. Always follow recommended safety practices, use appropriate protective gear, and ensure your bandsaw is properly working.

Prioritizing safety alongside these factors contributes to a holistic approach to a successful and secure woodworking experience.