How to Cut Door Hinges? A Step-by-Step Guide for Perfect Fit

To cut door hinges, first measure and mark their exact positions on the door edge and frame using a pencil and square.

Use a router with a hinge template or a sharp chisel to carefully create mortises that fit the hinge leaves flush. Score outlines to avoid tear-out, then drill pilot holes for screws, ensuring they’re straight and countersunk.

Gradually fit and tighten screws without overdoing it. For a flawless, professional finish, there’s more to master beyond these basics.

Key Takeaways

- Measure and mark hinge positions on door and frame, using consistent backsets and reference points for accurate alignment.

- Use a router with a hinge template or straight bit to cut precise mortises to the hinge leaf thickness in incremental passes.

- Score hinge outlines with a utility knife and clean mortise edges with sharp chisels, chiseling from center outward for accuracy.

- Drill pilot holes for screws with a bit matching screw diameter and create conical recesses to seat screw heads flush.

- Install screws by hand first, tighten gradually to avoid splitting wood, and ensure hinges are flush and properly aligned.

Tools and Materials Needed for Cutting Door Hinges

When preparing to cut door hinges, you’ll need to take into account both the hinge type and material, as these factors directly influence the tools and techniques you’ll use.

For typical residential hinges like butt, mortise, continuous, or ball-bearing, you’ll select tools based on hinge thickness (1.8–3.2 mm) and metal hardness.

Using proper jigs or guides can help maintain consistent pressure and positioning, similar to how a featherboard stabilizes workpieces in woodworking.

Use a compact router with a straight or hinge-mortising bit for clean, consistent mortises. An oscillating multi-tool helps in tight spots, while saws with metal blades cut hinge barrels carefully.

Hand tools such as sharp chisels (½”–1″), utility knives for scoring, and files for fine-tuning are essential for detail work.

When chiseling, it is important to make firm, shallow cuts spaced no more than approximately 2 mm apart to ensure clean flakes and avoid damaging the wood.

Don’t forget clamps and hinge template jigs to secure parts and guide routing precisely. Use carbide or metal-cutting blades for hardened steel or plated finishes to avoid damage and burrs.

Applying consistent pressure and control as a featherboard does can enhance safety and accuracy when cutting metal hinges.

Measuring and Marking Hinge Positions

Start by accurately measuring and marking hinge positions on both the door and frame to guarantee proper alignment and smooth operation. Correct hinge positioning ensures smooth, long-lasting operation of the door.

Maintaining a comfortable working height based on your ergonomics and user comfort can help reduce fatigue during precise marking.

Measure down 7 inches from the door’s top edge for the top hinge and up 11 inches from the bottom for the bottom hinge.

For a three-hinge door, center the middle hinge evenly between these points. Transfer hinge centerlines to the door edge by measuring a 3/8 to 1/2 inch backset and scribe square lines with a try square.

Repeat these steps on the frame, using the top of the frame or finished floor as reference points. Use a sharp pencil or marking knife for precise lines, and score the hinge perimeter to prevent chipping. Double-check orientation and swing direction before finalizing your marks.

Using a Router Template to Cut Hinge Mortises

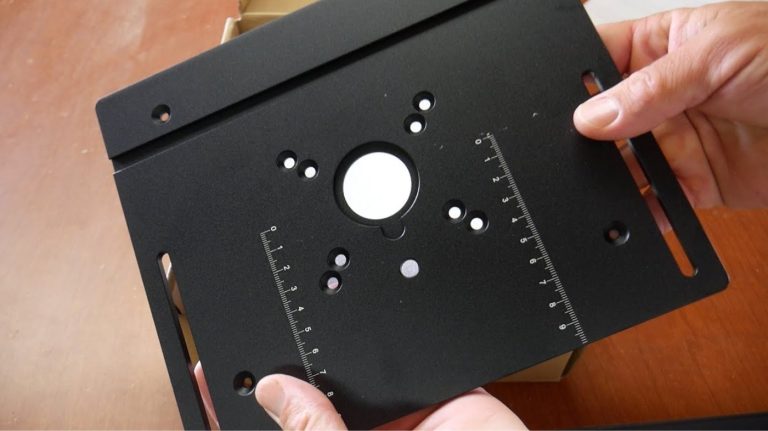

After marking and scoring the hinge positions on your door and frame, you can use a router template to cut accurate mortises quickly and consistently. Choose an MDF or plywood template sized to your hinge, either a full-size single hinge pattern or a multi-hinge strip for repeat cuts.

Attach a hardwood fence to the template plate for firm registration against the door edge. Secure the template with clamps or screws where fasteners will be hidden under the hinge or doorstop.

Use a pattern bit with a bearing or a guide bushing with an adjusted template size to match the hinge shape precisely. Set your router depth to the hinge leaf thickness and make incremental passes to avoid tear-out.

For large templates, mount the router on a plate or sled to maintain control and consistent mortise depth. Ensure your router setup is stable and aligned properly to maintain smooth cutting and avoid errors during the mortising process.

Hand-Chiseling Techniques for Hinge Mortises

Position the hinge carefully on the door edge with the knuckles pointing toward the door’s opening direction. Then trace its perimeter sharply with a pencil.

Score the outline deeply with a utility knife to prevent fiber tearing. Mark the mortise depth on your chisel using tape.

Begin by tapping the chisel along the scored lines with the flat back facing away from the mortise. Set points at both ends and drag a marking gauge for a depth line.

Make shallow cuts across the mortise, bevel down, chipping from center toward edges to protect grain. Use a wide chisel bevel up in a skew motion to level the base, supporting the chisel for even cuts.

Test-fit often, paring thin slices to achieve a flush, precise mortise. For enhanced accuracy and efficiency in woodworking projects, consider using tools with LED cut line indication to guide your cuts.

Drilling and Installing Hinge Screws Properly

Once you’ve chiseled the hinge mortise to a perfect fit, securing the hinge with screws requires careful attention to prevent wood splitting and guarantee proper alignment.

Start by marking screw locations with the hinge held flush, using a bradawl to punch centers. Drill pilot holes with a bit matching screw diameter, ideally 3/8 inch, using a self-centering bit if available.

Proper pilot holes prevent wood splitting and help screws go in straight. Ensuring you use the right pilot hole size also reduces increased vibration during screw installation.

Create a conical recess in the holes for screw heads. Install screws by hand initially, then tighten snugly without overtightening. Make sure screws enter perpendicular to keep the door level.

| Step | Tool/Material | Tip |

|---|---|---|

| Mark screw centers | Bradawl or nail | Align hinge flush |

| Drill pilot holes | 3/8″ drill bit | Use self-centering bit |

| Install screws | Phillips screwdriver | Tighten gradually |

Frequently Asked Questions

Can I Reuse Old Hinges After Cutting New Mortises?

Yes, you can reuse old hinges after cutting new mortises if their dimensions and screw patterns align with the new cuts.

Make sure to transfer hinge locations accurately and test-fit before final installation.

If the old hinges are warped, corroded, or don’t fit flush, minor adjustments or shims might help.

Fill any old mortises with epoxy or wood plugs to guarantee a stable surface.

Otherwise, consider replacing hinges for better reliability.

What Type of Wood Filler Works Best for Hinge Mortise Repairs?

Think of it like repairing a knight’s armor; you want something strong and reliable.

For hinge mortise repairs, use two-part epoxy wood repair compounds.

They provide exceptional strength and long-term stability, vital for load-bearing areas.

If you’re in a hurry, auto-body filler (Bondo) cures fast and sands smooth, ideal for painted jambs.

Avoid water-based fillers alone; they shrink and crumble.

For deep fills, combine wood plugs with epoxy for the best durability.

How Do I Prevent Door Sagging After Hinge Installation?

To prevent door sagging after hinge installation, use longer, high-grade screws, especially a 2½” screw in the top hinge that anchors into the jamb stud.

Shim hinge leaves precisely with thin, non-compressible shims to keep alignment without bending plates. Install three properly sized hinges to distribute weight evenly.

Reinforce weak jambs by filling stripped holes and adding metal plates or structural screws. Always pre-drill pilot holes to avoid splitting and make certain screws hold firmly.

Are There Special Hinges for Heavy or Exterior Doors?

Yes, you’ll want heavy duty hinges specifically designed for heavy or exterior doors.

These hinges support loads from 400 lbs up to 40,000 lbs, made from materials like stainless steel or reinforced steel for durability and corrosion resistance.

Look for ball bearing hinges with thick leaves and sizes up to 14″ x 12″.

Plus, choose mounting options like weld-on or mortised inserts to guarantee strong, long-lasting installation that handles the door’s weight and weather exposure.

How Do Temperature and Humidity Affect Hinge Fit Over Time?

Temperature and humidity cause wood around hinges to expand and contract, making fits tighter or looser over time.

You’ll notice swollen wood in humid conditions, which can bind hinges. Dry air shrinks wood, loosening screws and causing sagging.

Metal hinges can rust in moist environments, leading to noisy, stiff operation.

To keep your door fitting well, you’ll need to adjust screws and hinges seasonally to counter these natural shifts.

Put Your Skills to Work: Apply These Door Hinge Cutting Techniques

Cutting door hinges might seem like carving a puzzle, but with the right tools and steady hands, you’ll fit each piece perfectly.

Measure twice, mark clearly, and choose your method, either router or chisel, to carve clean mortises that let your door swing smoothly.

Drill screws carefully to secure your work.

Mastering these steps guarantees your door doesn’t just hang; it performs flawlessly, like a well-rehearsed dance every time you open or close it.