How to Adjust DeWalt Miter Saw for 45 Degree Angle?

To adjust your DeWalt miter saw for a 45-degree angle, start by loosening the miter angle detent plate screws. Align a square against the blade and fence, then rotate the saw head to lock it at 45 degrees.

For bevel adjustment, loosen the bevel lock knob, set the desired angle, and tighten the knob securely. Always verify alignment with a square after these adjustments. You’ll want to ensure accuracy in your cuts, and there’s more to master.

Key Takeaways

- Loosen the detent plate screws with a Torx bit to allow side-to-side movement for miter angle adjustment.

- Align a square against the blade and fence to ensure perfect 90-degree alignment before rotating to 45 degrees.

- Rotate the saw head to the 45-degree position and securely lock it in place using the detent lever.

- Verify the 45-degree angle with a square or angle finder after making adjustments for accuracy.

- Conduct a test cut to confirm precision before using the miter saw for your projects.

Preparation for Adjustment

Before you begin adjusting your Dewalt miter saw, gather the necessary tools to guarantee a smooth process.

You’ll need a digital angle gauge for precise measurements, a machinist square to ascertain squareness, and a carpenter square to check the table’s flatness.

An Allen key is essential for adjusting bolts, while a screwdriver or wrench will help you loosen and tighten screws. Additionally, securing your miter saw will enhance its overall stability during adjustments, ensuring accurate results.

Start by verifying the table’s flatness and checking that the fence aligns parallel to the blade. Inspect the blade condition to confirm it’s not bent or worn out.

Always unplug the saw for safety, and familiarize yourself with the controls and adjustment bolts. Additionally, keeping hands away from the blade during adjustments is crucial to avoid accidents.

Wearing safety gear and keeping your workspace clear will enhance safety during the process.

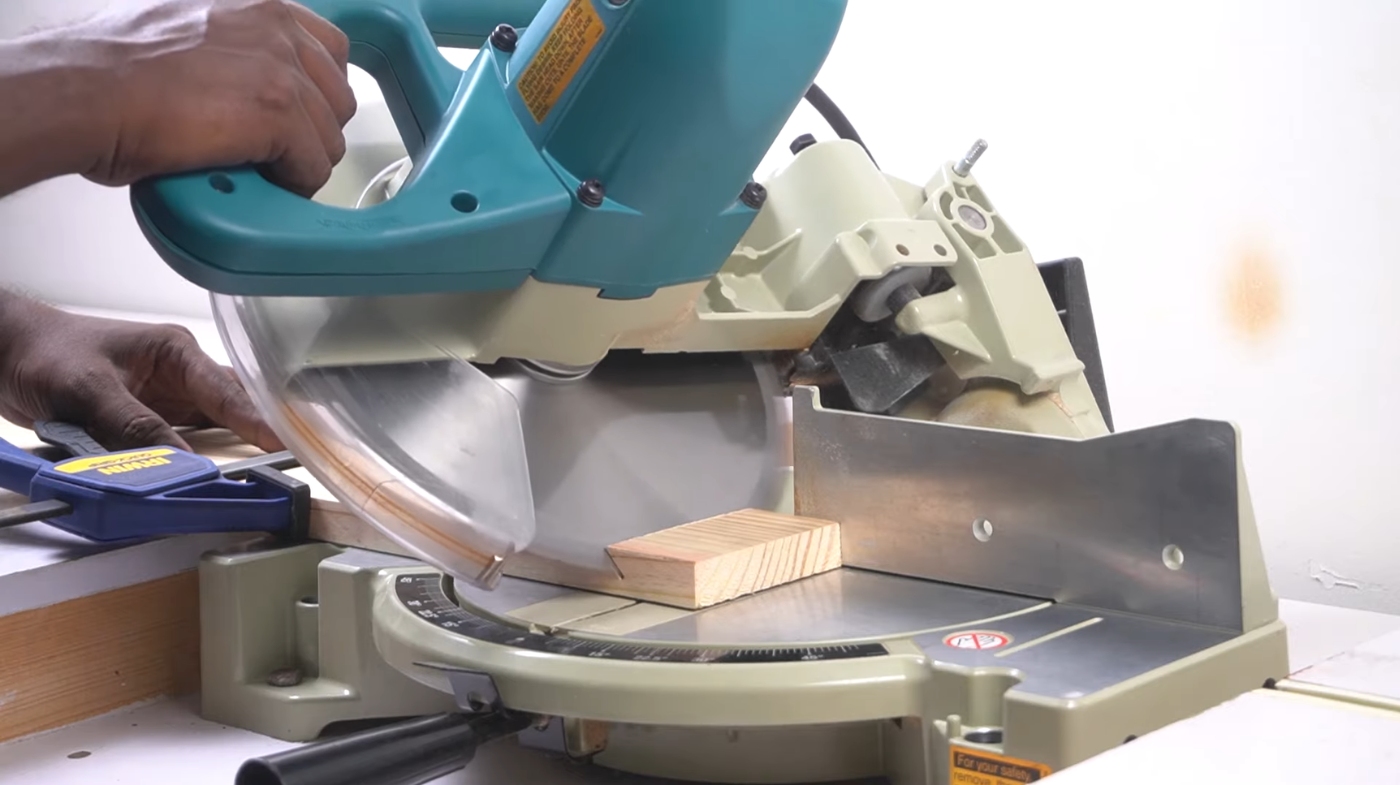

Miter Angle Adjustment

Adjusting the miter angle on your Dewalt miter saw is crucial for achieving accurate cuts. Follow these steps for a precise 45-degree angle adjustment:

- Loosen Detent Plate: Use a Torx bit to loosen the screws on the miter detent plate, allowing side-to-side movement.

- Align with Square: Position a square against the blade and fence to guarantee a perfect 90-degree alignment at zero miter angle. Regularly check and align saw components to ensure continued accuracy, as regular calibration of miter and bevel angles is essential for optimal cutting performance.

- Adjust for 45 Degrees: Rotate the saw head to 45 degrees, using the detent lever to lock it in place.

After making these adjustments, always verify the angle with a square or angle finder and conduct a test cut to confirm precision before proceeding with your project.

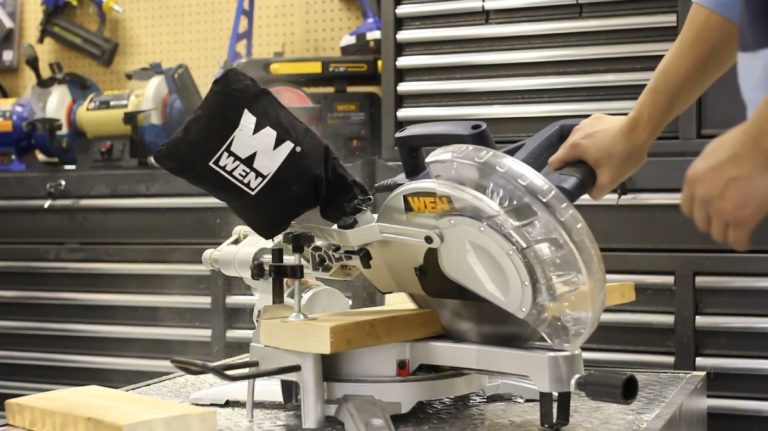

Bevel Angle Adjustment

To adjust the bevel angle, follow these simple steps:

Loosen Bevel Lock

Loosen the bevel lock knob to enable smooth adjustments of the bevel angle on your Dewalt miter saw. This step is essential for achieving accurate cuts at a 45° angle.

- Locate the bevel lock knob, usually on the back or side of the saw.

- Turn the knob counterclockwise to loosen it, allowing the saw head to pivot freely.

- Confirm the knob is fully loosened before moving the saw head to the desired angle. Regularly ensuring proper alignment of your miter saw can significantly enhance cutting accuracy. Proper setup and safety measures are crucial for ensuring successful cuts.

Remember to re-tighten the bevel lock knob once you’ve set your angle for secure operation.

Adjust Bevel Bolts

Once the bevel lock is loosened, you can proceed to adjust the bevel bolts for precise angle settings on your Dewalt miter saw.

Locate the bevel adjustment screws on either side of the bevel hub. Use an Allen key to loosen the bolts for the right 45-degree angle, then align the blade with the bevel pointer to guarantee it reads exactly 45 degrees.

Tighten the screws securely once the correct angle is achieved. Repeat this process for the left 45-degree angle, guaranteeing the bevel pointer also indicates 45 degrees.

After adjustments, verify accuracy with a digital gauge or machinist square. Additionally, ensure that you understand the difference between single vs double bevel saws to select the appropriate tool for your projects.

Finally, check that the blade aligns properly with the fence before making cuts.

Ensuring Accuracy

To ensure precise cuts with your DeWalt miter saw, follow these steps:

Check Blade Alignment

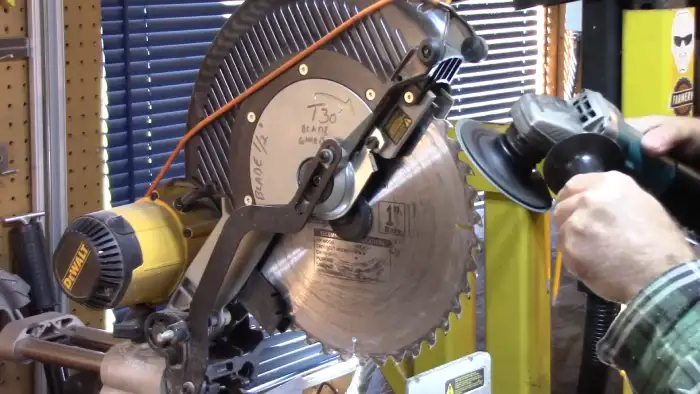

Before making any adjustments, it’s vital to guarantee your blade is accurately aligned, as even minor misalignments can lead to imprecise cuts.

Follow these steps to assure your blade’s accuracy:

- Inspect the Blade: Check for visible signs of wear, damage, or dullness. A fresh, sharp blade is critical for precise cuts, as blade sharpness greatly impacts cutting efficiency.

- Clear Debris: Remove any dust or particles from the saw table to prevent misalignment during your adjustments.

- Measure Squareness: Use a machinist square or digital gauge to confirm the blade’s squareness to the fence. Regularly checking the blade alignment ensures that your cuts remain accurate and professional.

Verify Table Leveling

Accurate table leveling is vital for achieving precise cuts with your Dewalt miter saw.

Begin by using a carpenter square and a straightedge to guarantee that the miter table and wings are on the same plane. Check for even alignment of the left and right fences, confirming no gaps between table sections. Fence alignment is crucial for preventing inaccuracies during cutting.

Prevent sagging by securely mounting the table and avoiding uneven surfaces that can cause binding. For adjustments, utilize shims or threaded inserts, and remember to tighten bolts without over-tightening.

Additionally, checking for flushness ensures that misalignment does not affect your cuts. After making adjustments, re-check with a straightedge to confirm levelness.

Troubleshooting Common Issues

When using a Dewalt miter saw, you might encounter several common issues that can affect its performance and accuracy.

Here are three troubleshooting tips to help you resolve these problems:

- Blade Alignment: If cuts aren’t straight, check the blade alignment. Use a square to adjust the bevel and miter settings accurately.

- Dust Collection: Inadequate dust collection can hinder performance. Regularly clean dust ports and consider using a shop vacuum for better control.

- Motor Overheating: If the motor overheats, allow it to cool down and check ventilation ports for debris. Verify you’re using quality blades to minimize heat buildup. Additionally, ensure that the saw is regularly maintained to prevent improper saw maintenance, which can lead to performance issues.

Maintenance and Verification

To keep your Dewalt miter saw performing at its best, regular maintenance and verification are essential. Follow this schedule to guarantee longevity and accuracy:

| Maintenance Task | Frequency |

|---|---|

| Regular Inspection | Every few months |

| Cleaning | After each use |

| Tightening Bolts | Monthly |

| Angle Verification | After adjustments |

Use a carpenter’s square to check flatness and alignment of the table and fence, and a digital angle gauge for bevel angles.

Confirm adjustments by loosening the detent plate screws and using a machinist square for precise measurements. Consistently verify alignments at various angles to maintain cutting performance.

Frequently Asked Questions

What Tools Are Needed for Adjusting the Miter Saw?

When tackling miter saw adjustments, think of your toolkit as a well-prepared chef’s knife set—vital and sharp. You’ll need a carpenter’s square for checking flatness, a digital angle gauge for precise readings, and a machinist square for those fine measurements.

An Allen key is important for loosening screws, while a speed square can help with quick alignments. Make sure you have everything on hand to make your adjustments smooth and efficient.

How Often Should I Calibrate My Miter Saw?

You should calibrate your miter saw regularly to maintain accuracy, especially after long-term use or transport. Check calibration every few months or whenever you notice accuracy issues. If you’ve moved the saw or if it’s been subjected to impacts, recalibrate immediately.

Additionally, keep an eye on the blade condition and verify your table and fence are clean and flat to support effective calibration.

Can I Adjust the Miter Saw Without a Manual?

You might think adjusting a miter saw requires a manual, but it doesn’t. Just grab a carpenter square or digital angle gauge for precision. Start by loosening the necessary screws to set your desired angle. Check that the table and fence are level.

With the miter lock engaged, you’ll secure your adjustments. Regular calibration guarantees your saw remains accurate and ready for any project, all without needing that manual.

Is It Safe to Adjust the Saw While Plugged In?

No, it isn’t safe to adjust the saw while it’s plugged in. Doing so poses serious electrical hazards and increases the risk of accidents due to unexpected movements.

Always unplug the saw before making any adjustments to guarantee your safety. Clearing the workspace and wearing personal protective equipment is essential, too.

What Should I Do if the Saw Blade Is Damaged?

If your saw blade’s damaged, start by inspecting it for dents or excessive wear. If you find any damage, replace it with a high-quality blade.

Always unplug the saw before you begin any work to guarantee safety. Use a blade wrench designed for your DeWalt miter saw to remove the old blade and install the new one. If you’re unsure about this process, consult a professional for assistance.

Set the 45-Degree Angle for Precise Cuts with Your DeWalt Miter Saw

In summary, adjusting your DeWalt miter saw for a 45-degree angle is like fine-tuning a musical instrument; precision is key for a harmonious cut.

By carefully following the preparation steps, making accurate angle adjustments, and consistently verifying your settings, you’ll achieve flawless results every time.

Remember, just as musicians practice to maintain their skill, regular maintenance of your saw will guarantee it performs at its best, making your projects not only easier but more enjoyable.