How Fast Does a Table Saw Blade Spin: Know the Truth

Table saws are more than just a powerful motor or a fancy blade. What makes them different is the speed at which their blades rotate. However, you might wonder what speed the blade spins that makes this tool so powerful.

Well, I found in my study that most direct drive table saws typically spin their arbors between 3,000 and 4,000 rpm or 130 and 170 Feet/Second based on their size. Yet, some jobsite table saw run at a striking 10,000 RPM with smaller saw blades.

But let me tell you one thing, the rotation speed of a table saw blade is affected by various factors. Throughout this article, I’ll explain what factors affect the speed, why it matters, and the recommended RPMs for different woodworking tasks. So, let’s start.

What Affects Table Saw Blade Speed?

I have found several key points that can affect a table saw blade speed, such as:

- Saw blade size

- Motor power and voltage

- Pulley ratios

- Tooth configuration and blade design

- Drive Type

- Anti-vibration technologies

- Blade sharpness and wear

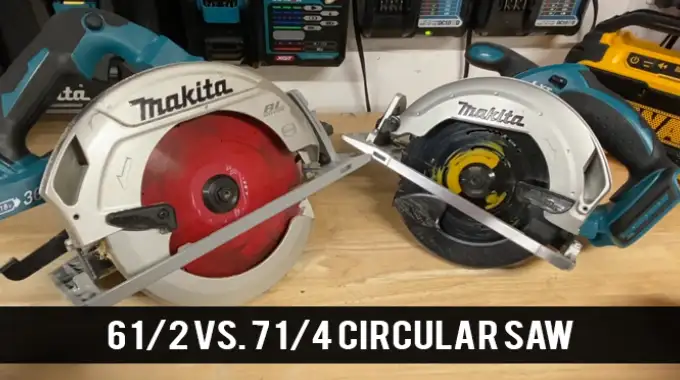

1. Saw Blade Size

The saw blade size is the most critical factor that affects table saw blade speed. As the diameter of the blade increases, the rotational speed decreases. This is because the same motor power is distributed over a larger circumference, resulting in a decrease in RPM (rotations per minute).

For example, a smaller 6 ½-inch blade may spin at approximately 10,000 RPM, while a larger 36-inch blade operates at around 2,000 RPM. Consider the impact of blade size and height on speed, as it directly influences the linear tooth speed and, consequently, the quality of the cut.

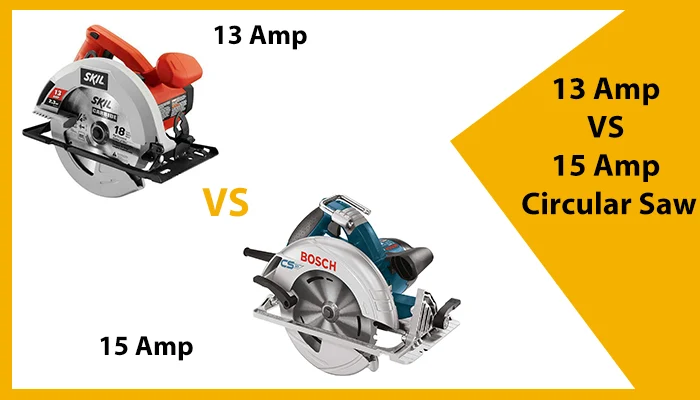

2. Motor Power and Voltage

When determining table saw blade speed, I often think about the motor’s size and power. The saw motor’s size and power directly impact the blade speed. A higher motor horsepower and voltage will result in a higher blade speed.

For instance, the Grizzly G0870 comes with a 20,000 RPM motor, while the Grizzly G0690 operates at a lower speed of 3,450 RPM.

3. Pulley Ratios

The pulley ratios between the motor and blade are crucial in determining the blade speed. By changing the size of the pulleys, you can increase or decrease the speed at which the blade spins.

For example, if you want to increase the blade speed, you can use a smaller pulley on the motor and a larger pulley on the arbor. Conversely, if you want to decrease the blade speed, you can use a larger pulley on the motor and a smaller pulley on the arbor.

4. Tooth Count and Configuration

The arrangement, count, and design of teeth on a blade are crucial in determining its rotational dynamics.

Blades with specialized configurations, such as alternating top bevel (ATB) or high alternate top bevel (HiATB), may have different speed requirements. These configurations affect the cutting action and efficiency of the blade, influencing the overall speed at which it should spin.

Additionally, the number of teeth on a blade can impact its speed. Blades with more teeth typically have a higher rotational speed to maintain optimal cutting performance.

5. Drive Type

The drive mechanism of a table saw, whether direct or belt drive, plays a crucial role in determining the speed at which the blade spins.

The blade speed is directly linked to the motor RPM in direct drive saws. This means that the blade spins at the same speed as the motor. Conversely, belt-driven saws offer more flexibility in adjusting the arbor speed independently from the motor RPM. This allows for achieving a faster arbor speed than the motor RPM.

The drive type is important for users who want to optimize their table saws for specific tasks by adjusting the blade speed accordingly.

6. Anti-Vibration Technologies

Exploring the impact of anti-vibration technologies on table saw blade speed, I’ve found that these advancements can significantly affect the rotation rate.

Blades with anti-vibration technologies are designed to reduce oscillations and enhance cutting precision. By minimizing vibrations, these technologies allow the blade to spin at higher speeds without compromising accuracy.

The construction of the blade plays a crucial role in its ability to resist vibrations. Features such as laser-cut expansion slots and dampening materials help to reduce vibrations and maintain a stable rotation speed.

7. Blade Sharpness and Wear

Blade sharpness and wear are also key factors influencing the speed at which a table saw blade spins. A sharp blade allows for cleaner and faster cuts, reducing the resistance encountered during cutting.

Alternatively, a dull blade can slow the cutting speed and lead to a higher chance of kickback. Over time, the blade can wear down due to the accumulation of sawdust, resin, and other debris. This wear can result in a decrease in blade performance and efficiency.

Why Does Table Saw RPM Matter?

The RPM of a table saw blade is a crucial factor that directly impacts your cuts’ efficiency, quality, and safety.

Efficiency of Cuts

The efficiency of cuts is primarily influenced by the speed at which the blade cuts through the wood. When the blade spins at a higher RPM, it can make quicker and smoother cuts, reducing the time required for each cut. This is especially important when working on large projects or dealing with thicker or harder types of wood.

A higher RPM allows the blade to slice through the wood more effectively, minimizing resistance and preventing the blade from getting bogged down. Additionally, faster cuts reduce the likelihood of tear-out and splintering, resulting in cleaner and more precise cuts.

Material Compatibility

Different materials have different characteristics, such as hardness and density, directly impacting the cutting process. Adjusting the table saw RPM based on the cut material is essential for achieving clean and precise cuts.

Blade Longevity

Matching the table saw RPM to the cut material ensures blade longevity. When the blade spins at the recommended RPM, it reduces the chances of excessive heat buildup and premature dulling or damage.

Operating the blade at higher speeds than recommended can lead to overheating, causing the blade to lose its sharpness faster and potentially warp or crack. Alternatively, operating the blade at lower speeds may result in inadequate cutting performance and increased friction, leading to premature wear.

Quality of Cuts

The RPM of the table saw blade directly affects the smoothness and precision of the cuts. A higher RPM generally produces cleaner cuts with minimal tear-out and a smoother finish.

This is because a faster blade speed reduces the chances of the blade getting caught or dragged through the material, which can lead to rough or uneven cuts.

However, a lower RPM may not provide enough cutting power, resulting in slower and less precise cuts. Therefore, adjusting the RPM based on the cut type and material used is crucial to achieving the desired quality of cuts in woodworking projects.

What Are the Recommended Speeds for Table Saw Blades for Woodworking?

When considering woodworking, consider the recommended speeds for table saw blades. Different materials require different speeds to achieve optimal results.

Hardwood

I recommend using a table saw blade with a higher tooth count and a finer tooth configuration for cutting hardwood, as it helps achieve smoother and more precise cuts.

The recommended speed range for cutting hardwood with a table saw blade is generally between 3,000 and 4,500 RPM (rotations per minute). This speed range allows the blade to cut through the dense material effectively without causing excessive heat buildup.

Softwood

The recommended speed range for table saw blades for softwood is between 3,000 and 5,000 RPM (rotations per minute). This range allows optimal cutting efficiency and reduces the wood’s risk of burning or chipping.

A general-purpose blade with a moderate tooth count is typically suitable for cutting softwood. Such a blade balances speed and precision, making it ideal for softer materials.

Plywood and Composite Materials

A blade with a high tooth count and alternate top bevel (ATB) or triple-chip grind (TCG) configuration is suitable for Plywood or composite materials.

The recommended speed range for cutting plywood and composite materials is typically between 4,000 to 5,500 revolutions per minute (RPM). This range allows for clean and precise cuts, reducing the chance of splintering or tear-out.

Exotic Woods

Exotic woods, known for their density and brittleness, require a slower blade speed than other materials. The ideal range for table saw blades working with exotic woods is 3,000 to 4,000 RPM (rotations per minute). This slower speed allows for better control and reduces the wood’s risk of chipping or splintering.

Rip Cuts

For woodworkers, the recommended rotation speeds for table saw blades for rip cuts range from 3,000 to 4,500 RPM. Rip cuts involve cutting wood along the length of the grain, requiring a blade with a lower tooth count and a more aggressive tooth configuration.

Crosscuts

For crosscutting across the wood grain, using a table saw blade with a speed ranging from 4,000 to 5,000 RPM (rotations per minute) is recommended. This speed range ensures optimal performance and clean cuts.

A blade with a higher tooth count and an ATB or TCG configuration is ideal. This blade minimizes tear-out and produces cleaner crosscuts by cutting through the wood fibers more effectively.

Dado Cuts

Regarding speed, the recommended range for table saw blades used for dado cuts is between 4,000 and 5,500 RPM (rotations per minute). This speed range ensures that the blade can efficiently cut through a wide portion of material while minimizing the risk of overheating or causing damage to the wood.

What is the average RPM of a standard table saw blade?

The typical RPM of most table saw blades is approximately 3,450. This rotational speed is optimal for cutting through various materials precisely and efficiently. The high RPM ensures that the blade can make clean and accurate cuts, reducing the risk of tear-out and minimizing the need for additional finishing work.

Also, operating at this speed helps to reduce the chances of kickback, a potentially dangerous occurrence where the workpiece is forcefully thrown back toward the operator.

Is blade RPM the same as arbor speed in a table saw?

Blade RPM and arbor speed in a table saw aren’t necessarily the same, especially in belt-driven saws where the arbor speed can be adjusted independently. Unlike blade RPM, arbor speed is the speed at which the arbor, or shaft that holds the blade, spins.

The RPM of the blade and arbor speed are usually the same in direct drive motors. However, in belt-driven saws, the arbor speed can be adjusted by changing the size of the pulleys or belts that connect the motor to the arbor.

Doing this lets you control the blade’s speed based on the cuts you’re making or the materials you’re using.

Optimize Your Woodworking Cuts With the Right Rotation Speed

The rotation speed at which a table saw blade spins is crucial in woodworking. It determines the efficiency and precision of the cuts made.

By considering standard RPM, blade size, and motor power, you can optimize your table saws for efficient, safe, and high-quality woodworking projects. It’s important to follow the recommended RPM for different types of wood and blade sizes to ensure optimal results.

The adage goes, ‘Measure twice, cut once’ – it emphasizes the importance of precision and careful planning in any woodworking project. Always adhere to manufacturer recommendations and safety guidelines to ensure the longevity of your blades and the precision of your cuts.