How Deep Can a Circular Saw Cut: Detailed Explanation

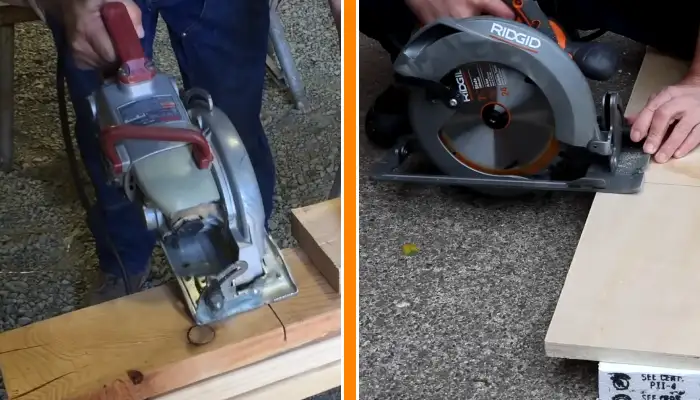

Circular saws are indispensable tools for cutting various materials such as wood, plastic, and metal. Understanding the depth that a circular saw can cut is crucial for ensuring precision and safety in any woodworking project.

According to my research, the size of the blade in a circular saw determines the maximum depth of a cut. For example, a 5 ½ inch circular saw can cut up to 1 ¾ inches at a 90-degree angle, while a 10 ¼ inch circular saw can make impressive single-pass cuts, reaching up to 3 11/16 inches at 90 degrees.

I will explain the variation in the cutting depth of circular saws based on blade size and other factors that affect cutting depth.

How Deep Can a Circular Saw Cut: Variations Depending on the Saw Size

Circular saws come in different sizes, and the cutting depth they can achieve varies accordingly. I listed the common sizes of circular saws and the associated cutting depth variations below:

- 5 ½ Inch Saw

- 6 ½ Inch Saw

- 7 ¼ Inch Saw

- 8 ¼ Inch Saw

- 10 ¼ Inch Saw

Now, explore the cutting depth variations associated with different sizes to understand how deep a circular saw can cut.

5 ½ Inch Saw

Regarding the 5 ½ inch saw, you can achieve a maximum depth of approximately 1 ¾ inches at a 90-degree angle. However, the cutting depth is reduced to about 1 3/16 inches when cutting at a 45-degree angle with a circular saw of this size. This smaller size blade is perfect for precise cuts that don’t require a lot of depth.

6 ½ Inch Saw

With the 6 ½ inch saw, you can cut up to 2 13/32 inches deep at a 90-degree angle, perfect for tackling bigger projects. However, when cutting at a 45-degree angle, the depth decreases to around 1 11/16 inches. This blade size is ideal for intermediate-level projects and balances depth and precision.

7 ¼ Inch Saw

The 7 ¼ inch saw is a common circular saw size that boasts a maximum cutting depth of 2 ½ inches at a 90-degree angle. However, at a 45-degree angle, the depth is slightly reduced to 1 13/16 inches. This versatile blade size can handle a range of projects, from small to medium-sized.

8 ¼ Inch Saw

With a larger blade size of 8 ¼ inches, you can achieve greater depths when cutting at a 90-degree angle, reaching approximately 2 7/8 inches.

Even at a 45-degree angle, you can still achieve a substantial depth of 2 ¼ inches. This blade size is perfect for tackling larger projects that require more depth, like cutting thick pieces of wood.

10 ¼ Inch Saw

For those looking to tackle the biggest projects, the 10 ¼ inch saw equipped with a larger blade is the way to go. This saw can cut impressively deep at approximately 3 11/16 inches when cutting at a 90-degree angle.

At a 45-degree angle, the cutting depth remains substantial at about 2 3/4 inches. This larger blade size is perfect for heavy-duty projects that require cutting thick pieces of lumber or other materials.

Other Factors Contribute to the Variation in the Cutting Depth of a Circular Saw

Beyond blade size, the cutting depth of a circular saw is influenced by various factors, each playing a crucial role in achieving precision and versatility.

1. Blade Design

The blade’s design, including its geometry, tooth configuration, and overall construction, can significantly impact the cutting performance and determine the achievable depth.

A blade’s geometry, such as the shape and angle of the teeth, affects how efficiently it can penetrate through different materials. Blades with larger gullets and more aggressive tooth profiles tend to have a greater cutting depth.

Additionally, the number of teeth on the blade can influence the cutting depth, with blades having fewer teeth generally cutting deeper.

Furthermore, the quality of the materials used and the manufacturing techniques employed can affect the performance and longevity of the blade, ultimately affecting the cutting depth.

Investing in a good quality circular saw blade ensures optimal performance and extends the life of your tool, contributing to precise and efficient cuts.

2. Footplate Adjustment

You can control the cutting depth of a circular saw by adjusting the height of the footplate using its adjustable features.

The footplate, also known as the base shoe, is an essential component of the circular saw that determines the depth of the cut. Raising or lowering the footplate lets you adjust the cutting depth based on the material thickness.

This adjustment feature allows you to precision- and control-over the saw’s performance, achieving accurate and consistent cuts.

It’s important to note that the footplate should be securely locked in place after making the necessary adjustments to ensure safety and optimal cutting results.

3. Bevel Capacity

The bevel capacity of a circular saw not only affects the angle of the cut but also contributes to the variation in the cutting depth. When you tilt the saw blade for bevel cuts, the effective cutting diameter changes, directly impacting the cut’s depth.

In degrees, bevel capacity refers to the maximum angle at which the saw can make bevel cuts. This angle affects how the blade enters the material and the resulting depth of the cut. A higher bevel capacity allows for steeper angled cuts, but it also reduces the cutting depth.

Conversely, a lower bevel capacity limits the angle of the cut but increases the cutting depth. Understanding and adjusting the bevel capacity is crucial for achieving accurate and consistent cuts at different angles while considering the impact on cutting depth.

4. Theoretical Depth Calculation

Calculating the theoretical depth of a circular saw cut involves considering various factors contributing to the cutting depth variation. The blade’s radius is a crucial element in this calculation. A larger blade radius results in a deeper cut, while a smaller radius yields a shallower cut.

Additionally, the flange nut or arbor diameter affects the cutting depth. A wider nut or arbor allows for a greater depth, whereas a narrower nut or arbor limits the depth.

Another consideration is the thickness of the footplate. A thicker footplate reduces the cutting depth, while a thinner footplate increases it. Lastly, safe distances must be taken into account to avoid damaging the saw or compromising safety.

How do I adjust a circular saw’s cutting depth?

To adjust the depth of cutting on a circular saw, start by powering off the tool and locating the depth adjustment knob usually found near the blade on the saw’s body. Make sure the saw is unplugged, and then loosen the adjustment knob.

Next, slide the footplate or base shoe up or down, depending on whether you want to increase or decrease the cutting depth. Follow the same steps for a 6 ½ inch or a 7 ¼ inch circular saw. Carefully measure the desired depth, considering the thickness of the material you’re cutting.

Once set, securely tighten the adjustment knob to lock the chosen depth in place. To ensure accuracy, perform a test cut on a scrap piece of material before making any real cuts.

Can you cut through 4×4 lumber in a single pass with a circular saw?

Cutting 4×4 lumber with a circular saw in a single pass is possible, particularly with a larger blade size such as a 10 ¼ inch circular saw. These larger blades offer significant cutting depth, facilitating efficient and effective cuts in one pass, thereby saving considerable time and effort.

However, it is crucial to adjust the saw appropriately for specific material thickness and adhere to recommended guidelines for optimal performance and safety. To achieve accurate and safe results, consider the capabilities of your circular saw, ensure a sharp blade, and take necessary safety precautions when tackling such tasks.

Use the Appropriate Blade Size for the Required Cutting Depth

You now understand how blade size affects cutting depth, exploring variations based on common blade sizes I’ve explained. Each size caters to specific project requirements, from the versatile 5 ½ inch saw to the robust 10 ¼ inch saw.

Additionally, you’ve investigated other factors that shape cutting depth, such as blade design, footplate adjustment, bevel capacity, and theoretical depth calculation. As a result, adjusting the cutting depth on your circular saw becomes a precise task, ensuring safety and accuracy in your woodworking endeavors.

Embrace the versatility of your circular saw, knowing its capabilities and optimizing your cutting depth for every project.