Grizzly Table Saw Review: Key Features and Benefits

If you’re looking for a Grizzly table saw, expect models with powerful 1 to 15 HP motors, durable cast iron tables, and precise 10″ blade cuts up to 3-1/8″ deep.

Safety features include quick-change riving knives and overload protection, though flesh-detection isn’t standard. You’ll find options tailored to portability, heavy-duty cabinet use, and full-sheet ripping.

Maintenance is essential for performance and warranty compliance. Exploring further reveals detailed specs, applications, and how to maximize your saw’s efficiency.

Key Takeaways

- Grizzly table saws offer a variety of models from 1 HP to 15 HP, suitable for different woodworking tasks and power requirements.

- Most models feature durable cast iron tables, 10-inch blades, and rip capacities ranging from 31 to 52 inches for versatile cutting.

- Safety features include quick-change riving knives, anti-kickback devices, thermal overload protection, and large STOP paddles for enhanced user protection.

- Maintenance involves regular V-belt inspection, dust cleaning, and protecting cast iron surfaces with wax or talcum powder for longevity.

Grizzly Table Saw Models Overview

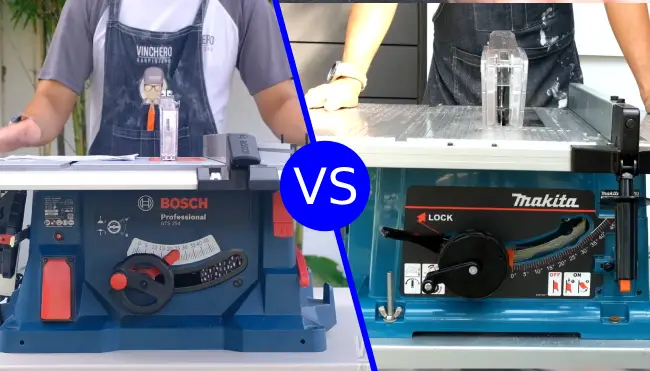

Although Grizzly offers a diverse lineup of table saws, you’ll find each model tailored to specific woodworking tasks through variations in power, design, and functionality.

Their models range from 1 HP to 15 HP, covering cabinet, hybrid, sliding, jobsite, and rip saws. Most use 10-inch blades and operate on 120V or 240V motor power, depending on your workshop setup.

Tables are usually solid cast iron for durability and precision. For example, the G1023RL cabinet saw delivers a 3 HP motor, 40″ x 27″ table size, and a 32″ ripping capacity, which is comparable to the rip capacity found in professional cabinet saws.

Hybrid models like the G0899 balance portability and power, featuring safety elements like riving knives included. Each model’s design optimizes cutting capacity, bevel angle, and dust collection for its intended use.

Key Features and Benefits of the Grizzly Table Saw

There are several standout features that make Grizzly Table Saws an excellent choice for both professionals and hobbyists alike. Below are some key features and benefits:

- Includes full manufacturer warranty

- Includes full manufacturer warranty

- Includes full manufacturer warranty

Motor Power and Performance

You’ll find Grizzly table saws equipped with motors ranging from 2 to 5 horsepower, delivering RPMs between 3450 and 4200 for efficient cutting speeds. These motors provide sufficient power for a variety of cutting tasks, enhancing the saw’s overall versatility in the workshop.

The higher RPM models, like the 3 HP G1023RL, achieve rim speeds up to 11,000 FPM, enhancing cutting precision and power. This level of performance is comparable to that of many cabinet saw motors, which are known for handling substantial wood pieces with ease.

Additionally, thermal overload protection safeguards the motor during heavy-duty use, ensuring consistent performance and longevity. The G0771Z model features a 2 HP motor prewired for 120V, providing versatile power options for various workshop setups.

Motor Horsepower Options

Grizzly offers table saw motors ranging from 1 HP to 15 HP, accommodating everything from light-duty rip cuts to heavy industrial tasks. Cabinet saws, like the G1023RL, typically feature 3 HP motors, ideal for continuous, demanding cuts and ripping up to 32 inches.

The G1023RL is recognized as Best Value by Fine Woodworking Magazine and features a 3 HP motor that rotates the arbor at 4200 RPM. This higher horsepower provides faster cutting speeds and smoother cuts essential for professional use.

Hybrid models often use 2 HP motors, balancing power and efficiency. More horsepower translates to greater cutting capacity, allowing you to handle thicker materials and longer rip cuts without strain.

However, 1.75 HP models may be more suitable for hobbyists with lighter workloads and smaller projects. Keep in mind, higher horsepower motors require appropriate electrical circuits—usually 240V with higher amperage—and may produce more noise and vibration, though designs like TEFC motors mitigate this.

RPM and Cutting Speed

Grizzly table saws offer arbor speeds ranging from 3450 to 4200 RPM, with blade diameters typically at 10 or 12 inches. This combination directly influences cutting speed, where higher RPM paired with appropriate motor horsepower guarantees efficient material removal and clean cuts.

Maintaining consistent arbor speed under load is critical; a high HP motor sustains RPM during demanding cuts, while insufficient power leads to bogging down.

The synergy of RPM and horsepower optimizes performance across wood types and cut angles. The G0696X model, for example, features a 5 HP 220V motor that delivers robust and consistent power for heavy-duty cutting tasks.

Additionally, efficient power transfer systems, such as poly-V belts, enhance speed consistency and reduce noise, further refining cutting precision and operational efficiency.

Thermal Overload Protection

Although powerful motors drive Grizzly table saws to handle demanding cuts, thermal overload protection guarantees these motors operate safely and reliably under heavy loads.

This feature uses magnetic switches paired with thermal sensors to monitor motor temperature continuously, automatically cutting power when overheating occurs.

The 7-1/2 horsepower motor spins the blade at a high speed of 3600 RPM, providing efficient cutting performance. Motor speed This prevents damage and accidental restarts, ensuring user safety and equipment longevity.

You’ll appreciate these key benefits:

- Reliable motor shutdown during thermal stress, avoiding costly repairs

- Lock-out padlock system that secures the power switch, preventing unauthorized use

- CSA and UL certifications confirming compliance with stringent safety standards

Cutting Capacities and Precision

When you need to handle large sheet goods or thick stock with precision, Grizzly table saws deliver exceptional cutting capacities and accuracy.

The G0699 model offers a crosscut capacity up to 126″, while the G0764Z features a sliding table exceeding 10 feet and rip capacity of 51-1/4″.

Both support thick cuts—4-1/8″ max depth at 90° (G0764Z) and 3-5/16″ (G0699).

Capable of handling thick materials with maximum cutting depths of 4-1/8″ on the G0764Z and 3-5/16″ on the G0699.

Precision stems from micro-adjustable rip fences, alloy crosscut fences with 45° mitering, and independent scoring blades that prevent tear-out.

Steel ball guides with heat-treated ways guarantee smooth sliding action. The saws also include a large overhead blade guard with dual dust ports to maintain a clean working environment.

Dual-motor designs separate scoring and main cuts, and blade tilts range 0-45° for bevels. Repeatability enhances with flip stops and precision-ground tables, letting you execute consistent, accurate cuts on oversized, dense materials.

- Motor: 3 HP, 240V, single-phase, 14A, 3450 RPM

- Solid cast iron table is first heat treated for strength then milled perfectly flat and ground to a…

- Extension table: 44″ x 27″

Safety and Dust Management Systems

Because safety is paramount in table saw operation, Grizzly models incorporate essential features like blade guards, splitters, and anti-kickback devices to minimize injury risks during cutting. These guards also help contain wood chips and debris, improving visibility during cutting.

You must also use push sticks for narrow ripping and maintain proper operator positioning to reduce kickback hazards. However, Grizzly lacks advanced flesh-detection systems and automatic blade stops, so vigilance and manual safety protocols are crucial.

In contrast, some saws feature a patented Safety System that stops the blade on skin contact within milliseconds to prevent serious injuries.

Dust management relies on open-base designs and external ventilation; Grizzly doesn’t include integrated extraction, so you’ll need third-party attachments and PPE like dust masks to control airborne particles effectively.

Key safety and dust considerations:

- Rely on guards and anti-kickback devices to prevent contact and ejection

- Use proper ventilation and aftermarket dust collection for cleaner workspaces

- Maintain focus and follow operational protocols to avoid injury risks

Table Saw Types and Their Applications

There are several options available within the Grizzly table saw lineup, each designed to meet specific woodworking needs. Below are the most common types and their ideal applications:

Cabinet Saws Overview

Cabinet saws deliver exceptional power and precision, making them essential for professional woodworking and heavy-duty projects. You’ll benefit from their robust 3 HP motors and cast-iron tables that provide unmatched stability and vibration reduction, ensuring every cut is accurate and smooth.

Their design supports handling large workpieces and dense materials effortlessly, perfect for intricate furniture making or industrial tasks. Most models feature T-square-style rip fences that lock solidly and glide smoothly, enhancing accuracy for rip cuts.

When you choose a cabinet saw, you get:

- Superior dust collection for a cleaner workspace

- Advanced safety features like automatic blade stops

- Durable components built for long-term, heavy-use reliability

These machines demand space and regular maintenance but reward skilled users with precision and efficiency unmatched by other table saw types. They’re an investment in quality and performance.

Hybrid and Portable Options

When you need a balance between power and footprint, hybrid table saws present a compelling option that combines cabinet-style features with contractor saw affordability.

Models like the Grizzly G0771Z deliver 2 HP motors, enclosed cabinet designs, and cast-iron trunnions mounted to the cabinet for enhanced durability. You’ll get precision-ground cast iron tables with 40″+ work surfaces and integrated 4″ dust ports for improved collection.

Hybrid saws have trunnions bolted to the bottom of the cast iron table, which can lead to slight sagging over time but maintain good overall stability. They also feature safety systems such as blade guards and riving knives to protect users during operation.

Compared to contractor saws, hybrids offer greater rip capacity—up to 31″—and cleaner motor enclosures that reduce dust buildup. However, hybrids weigh more (over 320 lbs) and lack the portability of lighter contractor saws.

While their fence systems and horsepower don’t match premium cabinet saws, hybrids excel in small-shop woodworking, dado cutting, and dust-sensitive environments, all on standard 120V circuits with professional-level accuracy.

Frequently Asked Questions

Can Grizzly Table Saws Be Used for Metal Cutting?

You might wonder if your table saw can handle metal cutting, but hold on—it’s not straightforward. Most standard saws spin blades at around 4,000 RPM, ideal for wood but risky for metals needing slower speeds to avoid overheating.

Plus, without specialized blades, coolant systems, or reinforced fences, you risk damaging your machine and facing safety hazards.

Are Replacement Blades Compatible Across All Grizzly Models?

You can’t assume replacement blades fit all Grizzly models because each has specific blade sizes and arbor configurations. For example, the 3-1/8″ scoring blade only suits the G0623 series. Arbor sizes vary, and discontinued models may lack parts, complicating compatibility.

To guarantee peak performance, match blades precisely to your model’s specifications. Sometimes, custom adapters or machine-shop modifications become necessary when parts are obsolete.

What Accessories Are Recommended for Beginner Users?

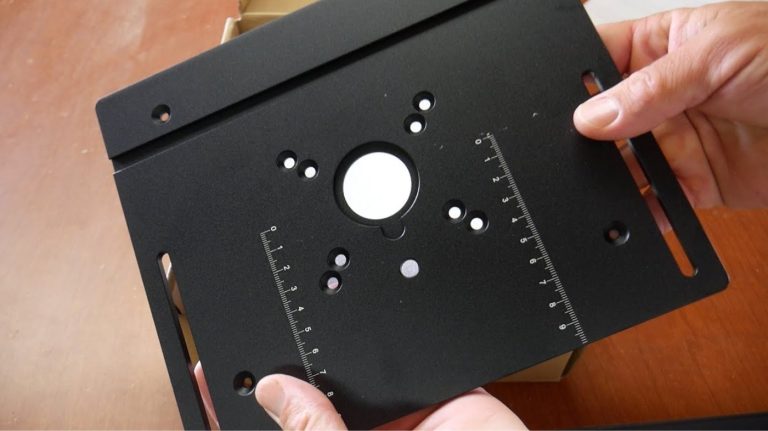

Before you even cut, safety’s key. You’ll want a riving knife and anti-kickback pawls to prevent kickback surprises. Don’t forget push sticks or blocks to handle narrow stock safely. Magnetic featherboards keep your workpiece steady, while zero-clearance inserts minimize tearout for cleaner cuts.

For beginners, these accessories enhance control and precision, making your first cuts safer and more accurate without overwhelming complexity.

Do Grizzly Table Saws Support Remote or Smart Controls?

You won’t find remote or smart controls on this saw. It lacks wireless connectivity or smartphone app integration, so you’ll rely entirely on its onboard digital interface.

Adjustments like blade height, angle, and scoring blade position require manual input through physical keypad buttons. There’s no IoT, API support, or preset memory for settings, so all controls are localized and must be made directly at the machine’s control panel.

How Noisy Are Grizzly Table Saws During Operation?

Grizzly table saws run as quietly as a whisper compared to portable saws with universal motors. You’ll notice their induction motors produce lower noise levels, especially in stationary models with heavy bases and well-insulated motors.

Proper blade and fence alignment further reduces any loud, repetitive noise. While benchtop units may be louder than stationary ones, they still operate quieter than most jobsite alternatives, creating a more pleasant, less disruptive workspace environment.

Grizzly Table Saws: The Ultimate Choice for Precision and Power

You’ll find Grizzly table saws deliver dependable, dynamic performance with powerful motors and precise, professional-grade cutting capacities. Their safety systems and smart dust management make maintenance manageable and your workspace more welcoming.

Whether you’re tackling tough tasks or trimming tiny details, these table saws combine technical tenacity with thoughtful design. With solid warranties and supportive customer service, Grizzly stands as a strong, savvy solution for serious saw users seeking superior strength and sharp, seamless results.

- Get all of the benefits of a Sliding Table Saw in a size that will fit any shop

- Large size panels are fully supported by the sliding table making ripping and cross cutting almost…

- The scoring blade eliminates tear-out for factory fresh edges every time and dust control is handled…

Last update on 2026-03-06 / Affiliate links / Images from Amazon Product Advertising API