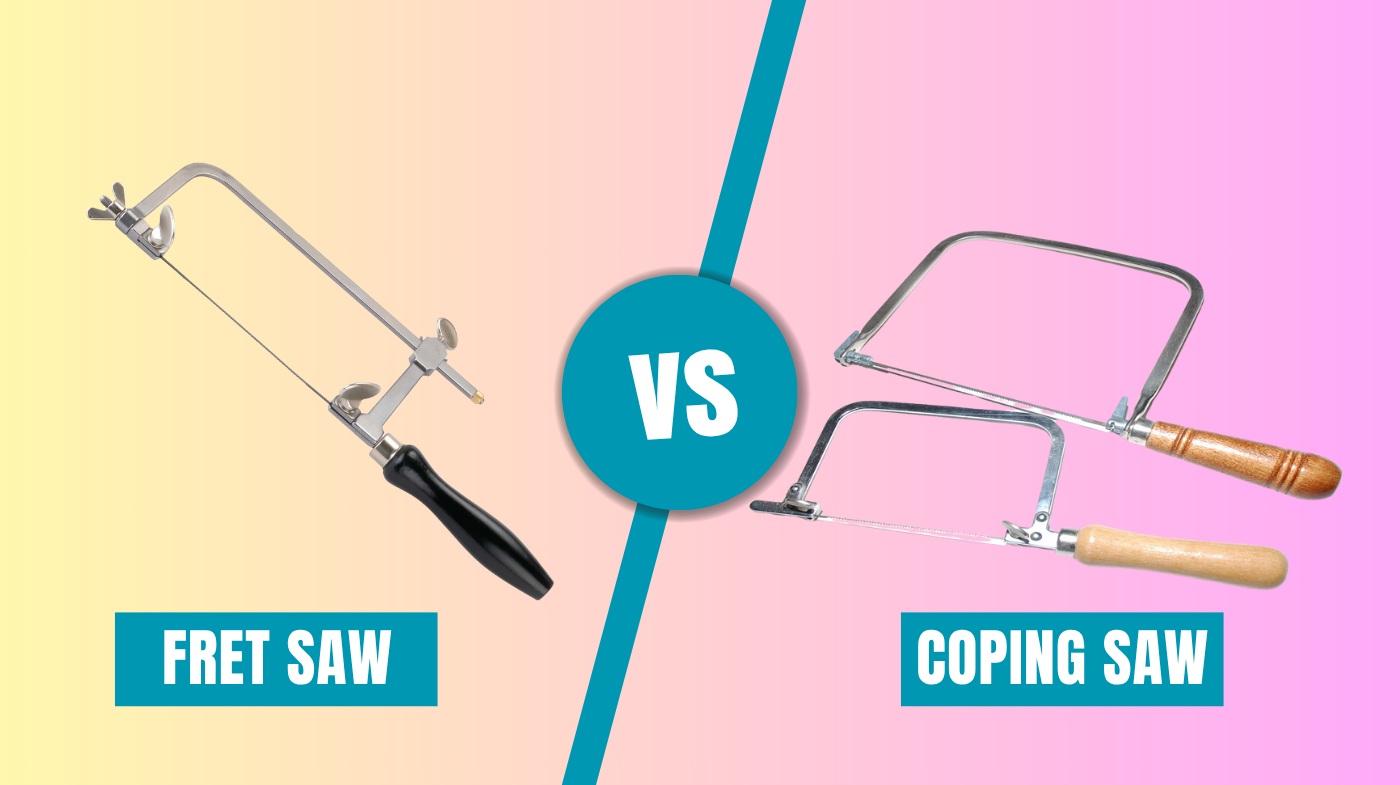

Fret Saw vs Coping Saw: Key Differences You Need to Know

When choosing between a fret saw and a coping saw, consider your project’s needs. Use a fret saw for delicate, precise cuts on thin wood or veneers, it excels at tight curves and intricate interior shapes thanks to its thin blades and deep frame.

Opt for a coping saw if you need faster, rougher cuts on thicker materials like molding or plywood, benefiting from its sturdier blade and shallower frame. For a deeper understanding of which saw fits your task best, keep exploring their features and uses.

- Swivel blade clamp model; can rotate the saw blade a full 360, with click stops every 45

- Heavy duty version of Standard Knew Concepts Fret Saw

- Cam Lever Tension is designed for rapid, repetitive blade changes

- High-speed steel coping saw blades cut through most materials with ease

- A Flat-Bar frame and DuraSteel pins on this coping saw provide durable use

- This coping saw has an ergonomic ProTouch handle to give added comfort

Key Takeaways

- Fret saws have deeper frames and thinner blades for precise, delicate cuts in thin materials and intricate internal shapes.

- Coping saws feature shallow frames and thicker blades for faster, rougher cuts in thicker wood and general carpentry.

- Fret saw blades have high teeth per inch (up to 32 TPI) for smooth, detailed cutting but are fragile and require careful tensioning.

- Coping saw blades are more durable with lower TPI (12-18), suitable for aggressive cutting and easier blade replacement.

- Fret saws excel in fine woodworking like marquetry and model-making, while coping saws are versatile for trimming, joints, and thicker material work.

Fret Saw vs Coping Saw Comparison Table

| Feature | Fret Saw | Coping Saw |

|---|---|---|

| Primary Use | Intricate, delicate cuts in thin materials | General woodworking and faster cuts |

| Material Thickness | Up to 1/4 inch (thin materials) | Up to 1/2 inch or more (thicker materials) |

| Blade Characteristics | Thinner blades with up to 32 TPI | Thicker, more robust blades with 12-18 TPI |

| Frame Design | Deep U-shaped frame (10-20 inch throat depth) | Shallow C-shaped frame (4-6 inch throat depth) |

| Cutting Speed | Slower, precise cuts requiring careful handling | Faster, more aggressive cutting |

| Best For | Fine woodworking, marquetry, model-making | Trimming moldings, coping joints, general carpentry |

| Blade Flexibility | Fixed blade orientation | Rotatable blade for varied cutting angles |

| Durability | Fragile blades prone to breaking | Durable blades resistant to breakage |

| Precision Level | High precision for detailed work | Moderate precision for general tasks |

| Ideal Materials | Thin wood veneers, soft plastics, thin metals | Hardwoods, plywood, thicker plastics |

Differences in Blade Thickness and Teeth Per Inch

While both fret saws and coping saws serve cutting purposes, their blade thickness and teeth per inch (TPI) differ considerably, affecting how you use them.

Fret saw blades are much thinner and have a finer tooth count, often up to 32 TPI, which lets you make precise, smooth cuts on thin materials under 1/4 inch.

This thinness allows tight curves and sharp corners but makes the blades fragile and prone to breaking if you apply too much pressure or cut thicker stock. In contrast, coping saw blades are thicker and more robust, with coarser teeth usually between 12 and 18 TPI.

These blades cut more aggressively and handle thicker, tougher materials up to 1/2 inch, sacrificing some precision for durability and speed.

Additionally, fret saws maintain higher blade tension, which is crucial for achieving the detailed and clean cuts required in delicate work.

Frame Design and Throat Depth Comparison

Because the frame design directly influences how you maneuver the saw and access your workpiece, understanding the differences between fret saw and coping saw frames is essential.

Understanding frame design is key to mastering saw maneuverability and workpiece access.

The coping saw features a compact, springy, C-shaped metal frame, letting you twist the blade for varied cuts and insert it through drilled holes. This blade rotation capability is crucial for making interior cuts and coping joints. Its lightweight handle materials, often rubber or plastic, contribute to comfortable grip and reduced vibration during use.

In contrast, the fretsaw’s frame is deeper, longer, and more delicate, made from forged steel or light alloy, providing rigidity but no blade twisting.

This design gives the fretsaw a throat depth of 10 to 20 inches, allowing cuts well inside large panels. The greater throat depth allows for more versatile cutting angles and enhanced accessibility in larger workpieces.

Meanwhile, the coping saw’s shallow 4 to 6-inch throat confines you to edges or small internal areas.

Primary Uses and Suitable Materials

You’ll find fret saws excel in delicate tasks like model-making and fine woodworking, cutting thin wood and soft materials with high precision. Their design allows for enhanced control during intricate cuts.

Coping saws handle thicker wood, plywood, and tougher plastics, making them better for general carpentry and trim work.

Choosing the right saw depends on the material’s thickness and the detail level your project demands. Additionally, coping saws are favored for their speed and robustness when cutting waste in wider workpieces.

Ideal Applications

When tackling intricate, delicate cuts, fret saws deliver unmatched precision thanks to their thin blades and flexible design, making them perfect for fine fretwork, marquetry, and tight curves in thin wood stock.

You’ll find them ideal for cutting small, complex shapes and detailed interior cutouts where minimal kerf and high accuracy matter.

On the other hand, coping saws suit heavier, more general woodworking tasks like trimming moldings or coping joints. Their thicker, sturdier blades handle thicker wood and faster, rougher cuts without specialized support.

If your project demands fine, artistic detail and thin materials, go with a fret saw. For robust, less intricate cuts in bulkier stock, a coping saw will serve you better.

Choose based on the precision you need and the thickness of your material. For enhanced cutting accuracy and precision in your woodworking projects, consider integrating a miter saw laser guide to reduce waste and improve results.

Material Compatibility

Although fret saws and coping saws might look similar, they serve distinct material compatibility roles that affect your project outcomes. You’ll find fret saws ideal for cutting very thin materials up to 1/4 inch thick, like delicate wood veneers, soft plastics, and thin metals.

Their fine, flexible blades with high teeth per inch let you make intricate cuts without breaking the material. The fret saw’s fixed blade orientation and deep frame also allow for precise control when working on detailed fretwork projects.

Using proper lubrication techniques can further enhance blade performance and lifespan during delicate cuts.

In contrast, coping saws handle thicker stock—up to 1/2 inch or more—such as hardwoods, plywood, and thicker plastics. Their robust blades with lower TPI resist breakage and cut faster but aren’t suited for delicate details.

The deeper fret saw frame lets you cut far from edges on thin materials, while coping saws excel in sturdier, general woodworking tasks where deep access isn’t essential.

Additionally, coping saw blades can be rotated and passed through drilled holes, enabling interior cuts in thicker materials blade rotation.

Blade Attachment Methods and Tensioning Techniques

Since blade attachment and tensioning directly affect cutting performance, understanding their differences in fret and coping saws is essential.

Fret saws clamp thin blades without pins, using thumb screws or levers for tension, allowing delicate, precise cuts. The design of fret saw blades, including their kerf width and tooth arrangement, is crucial for achieving accurate fret slots without damaging the wood.

Coping saws hold pinned, thicker blades, tensioned by twisting the frame, suited for tougher tasks. Proper tension avoids blade wobble or breakage in both saws, but mechanisms differ.

| Aspect | Fret Saw | Coping Saw |

|---|---|---|

| Blade Attachment | Pinless clamps secure blade ends | Pinned blades snap into frame holes |

| Blade Thickness | Thin, fine blades | Thicker, sturdier blades |

| Tensioning Method | Tighten clamps or adjustable screws | Twist frame or adjust screws |

| Blade Change Speed | Quick clamp release | Slightly more involved pin removal |

Cutting Capability and Speed Variations

When choosing between a fret saw and a coping saw, consider how speed and precision affect your project. Proper tool selection, including blade type and maintenance, can greatly influence cutting efficiency and reduce issues like blade gumming.

You’ll find coping saws cut faster and handle thicker materials, while fret saws excel at detailed, delicate work on thinner stock. The fret saw’s deeper throat and daintier blades make it better suited for intricate and high-detail cuts.

Speed Differences

Because cutting speed depends heavily on blade design, you’ll notice that coping saws and fret saws perform quite differently.

Coping saw blades are thicker and coarser, allowing you to cut faster through thicker materials and moderate curves. Their longer blades with deeper gullets clear waste wood quickly, speeding up your work.

Additionally, coping saw blades are secured with pins requiring larger holes, which influences the blade’s stability during cutting (blade secured with pins). The choice of blade also impacts cutting efficiency and cutting capacity.

In contrast, fret saw blades are thinner and finer-toothed, so you have to cut slower to avoid breaking them. Fret saws excel at tight, intricate curves but require careful, deliberate strokes and more skill.

The coping saw’s robust frame and pinned blade ends let you maintain higher speeds with less fatigue, while the fret saw’s delicate clamping system demands slower, controlled movements.

Precision Vs Power

Although both fret saws and coping saws serve similar purposes, their blade design and frame construction create distinct differences in precision and power.

You’ll find fret saw blades are thinner and finer, allowing tight curves but requiring delicate handling. The blades, often made of high-carbon steel, benefit from heat treatment to maintain sharpness and flexibility.

Coping saw blades, on the other hand, are thicker and coarser, which enables them to cut faster and through denser materials with more power. The frame depth also matters: fret saws have a deeper frame for intricate internal cuts, while coping saws offer robust, shallower frames for stronger cutting strokes.

Additionally, the blade attachment differs, with fret saw blades secured by a thumb screw and coping saw blades pinned at the ends, influencing blade tension and ease of replacement.

Keep these points in mind:

- Fret saws excel at precise, slow cuts with fragile blades.

- Coping saws deliver faster, more aggressive cutting with durable blades.

- Deeper fret saw frames aid detailed cuts; shallower coping frames support power.

- Stroke technique differs: fret saws need control; coping saws favor force.

Material Handling

Understanding the differences in precision and power between fret saws and coping saws sets the stage for examining how each handles materials during cutting.

You’ll find fret saws use thin, fine blades perfect for delicate cuts in materials up to 1/4 inch thick, excelling at intricate curves but requiring slower, careful strokes to avoid breakage. The fret saw’s deep frame allows for intricate detailed work that involves tight curves and sharp corners.

Their blades tend to have less cutting durability compared to more robust saw types, necessitating careful handling.

Coping saws, with thicker, coarser blades, handle thicker woods up to 1/2 inch or more, cutting faster thanks to deeper gullets that clear waste efficiently. Their pinned blades offer stability for aggressive cutting, and their shallower frames limit internal cuts.

While fret saws demand precision and patience, coping saws give you speed and robustness, making them better for general woodworking and longer, less intricate curves.

Handling and Maneuverability Factors

When you pick up a fret saw or coping saw, the frame design immediately influences how you handle and maneuver the tool. Fret saws have a deep U-shaped frame, letting you cut far from edges but making tight spaces tricky.

Coping saws feature a shallow C-shaped frame, which limits reach but excels in confined areas. The choice of frame design is similar to how bandsaw fences use different materials and build quality to enhance stability and usability.

Consider these factors for handling and maneuverability:

- Fret saws are heavier and may cause fatigue during long use.

- Coping saws are lighter, offering better balance and easier control.

- Blade tensioning on fret saws needs careful adjustment to avoid slipping.

- Coping saws allow longer, uninterrupted strokes without frame interference.

- Additionally, the frame space in fret saws is smaller, which allows for finer, more precise cuts.

Your choice depends on the workspace and the precision or speed you need.

Ideal Applications for Fret Saws

You’ll find fret saws excel when working on precision cutting tasks that demand fine detail and accuracy. Their thin blades handle delicate materials with minimal risk of damage, making them ideal for intricate design work.

The fret saw’s thinner, spiral blades allow for cutting very close to the baseline, providing exceptional precision. Whether you’re shaping tight curves or managing thin veneers, fret saws give you the control you need for clean, exact cuts.

However, attempting to retrofit a SawStop system onto a fret saw involves complex structural modifications that can compromise the tool’s integrity.

Precision Cutting Tasks

Although both fret saws and coping saws serve cutting purposes, fret saws excel at precision tasks that demand fine detail and delicate handling.

When you need accuracy for intricate patterns or tiny components, fret saws provide the control and blade finesse you require. Their high teeth-per-inch count and taut, narrow blade let you make tight curves and clean cuts without splintering.

Use a fret saw for:

- Intricate inlay and marquetry work with minimal fiber tear

- Cutting small decorative or craft pieces cleanly

- Model-making tasks requiring detailed, consistent cuts

- Removing waste in tight joinery spaces like dovetails

This precision reduces finishing work and preserves delicate designs better than coping saws. The lightweight design of fret saws enhances maneuverability and user comfort, making them ideal for extended precision work.

Thin Material Handling

Since thin materials demand careful handling to prevent damage, fret saws offer an ideal solution for cutting delicate wood veneers, plastic sheets, and soft metals. Their very thin, fine-toothed blades reduce splintering and minimize material waste by cutting with a narrow kerf.

You can easily make precise interior cuts on fragile stock, like inlay work or trimming veneer, without cracking or warping the substrate. Using proper supports such as a bird’s-mouth V-board stabilizes your workpiece, preventing vibration and ensuring clean, accurate cuts.

Just remember to apply light pressure and select the right blade size to avoid breakage. Fret saws excel in these tasks where delicate handling and fine control are critical, making them your go-to tool for thin-material woodworking projects.

Additionally, using the appropriate saw blades is essential when cutting materials like aluminum to ensure ease and safety.

Intricate Design Work

Handling thin materials with care naturally leads to projects that demand intricate design work, where precision cutting plays a major role. When you choose a fret saw for these tasks, you benefit from its fine, high TPI blades and fixed orientation, allowing you to execute tight curves and sharp corners with accuracy.

The larger frame depth lets you cut far from edges, perfect for complex internal patterns. Using a support tool can further stabilize your workpiece and protect your work surface during delicate cuts.

Consider these advantages when working on:

- Delicate scroll designs and pierced patterns in thin wood

- Intricate ornamental furniture details and musical instrument components

- Precise inlay and marquetry pieces requiring tight curve cuts

- Template-guided joinery and fretwork needing fine, controlled blades

Fret saws excel in detailed craftsmanship, outperforming coping saws for precision in intricate design work.

Versatility and Common Uses of Coping Saws

When you need a reliable tool for cutting a variety of materials, the coping saw proves highly versatile. It handles wood, plywood, plastics, and some metals with ease, thanks to its robust blade and C-shaped frame.

The saw features a thin steel or tungsten blade with 12-15 teeth per inch, allowing for precise cutting in various materials.

You can cut both straight and curved lines efficiently, even interior shapes by threading the blade through drilled holes. This makes it essential for coping joints in molding, fitting dovetails, and trimming waste in joinery.

It’s also great for furniture work, helping you shape curved parts and decorative edges. For DIY and home improvement, its portability and adjustable blade tension let you cut trim and molding quickly and precisely.

Maintenance and Blade Replacement Tips

Though fret saws and coping saws serve different cutting purposes, maintaining them follows similar principles to guarantee longevity and performance.

Keep blades clean by removing wax, oils, and sawdust after each use. Release blade tension when not in use to prevent warping or frame stress. It is important to release blade tension when the saw is not in use to avoid damage to the blade and frame.

Inspect blades regularly for burrs, dullness, or binding, sharpening or replacing as needed to maintain cutting precision. Also, check the frame stability and tighten any loose parts on coping saws.

To maintain and replace blades effectively, remember to:

- Use proper clamping or fixtures for safe blade handling.

- Match blade type and size to your cutting needs.

- Lubricate moving parts lightly to reduce wear.

- Store blades in a dry place to avoid rust and damage.

Selecting the Right Saw for Your Project

Since selecting the right saw can make or break your project’s success, you need to contemplate the type of cuts, material thickness, and level of detail required.

Use a fret saw for intricate, delicate cuts and deep interior access. Choose a coping saw for faster, broader cuts on medium-thickness wood and edge work. The fret saw’s fixed blade orientation and deep frame provide excellent control for intricate, detailed work.

| Feature | Fret Saw | Coping Saw |

|---|---|---|

| Blade Thickness | Thin, precise, prone to breakage | Thick, sturdy, reliable |

| Frame Depth | Deep throat (10-20 inches) | Shallow throat (~5 inches) |

| Typical Use | Fine fretwork, marquetry | Carpentry, molding, trim work |

Frequently Asked Questions

Can Fret Saws and Coping Saws Use the Same Blades Interchangeably?

You might think fret saws and coping saws share blades, but you’d be mistaken. Their blades differ in thickness, tooth count, and mounting style.

Using a fret saw blade in a coping saw risks breakage, while coping saw blades often won’t fit or perform well in a fret saw.

To avoid frustration and damage, always match the blade type to the saw designed for it—this guarantees better control and cutting precision.

Are There Ergonomic Differences Affecting Prolonged Use of These Saws?

You might think precision tools are always uncomfortable for long use, but ergonomic design changes that.

Saws with deeper frames allow longer cuts but can strain your wrists, while those with rotating blades reduce hand fatigue by letting you adjust blade angle easily.

Lower blade tension means less wrist stress during extended work. Choosing a saw with a comfortable grip and blade flexibility helps you work longer without discomfort or fatigue.

Which Saw Is Better Suited for Left-Handed Users?

You’ll find coping saws generally better for left-handed use because their open, C-shaped frame offers more flexible handling and easier blade tension adjustments. Their sturdier blades make control simpler, especially during longer projects.

While fret saws provide precision, their deeper frame can hinder comfort and sightlines for lefties. For most woodworking tasks, coping saws give you more forgiving maneuverability and quicker, reliable cuts.

Can Either Saw Be Adapted for Use in Powered Jigs or Machines?

You can adapt both saws for powered use, but they differ. You’ll find fret saw blades fit best in scroll saws, offering precise, fine cuts with adjustable tension.

Coping saw blades, being broader, easily fit into power jigsaws with t-shank mounts, enabling intricate and robust cuts.

Both require compatible machines and blade tension control, but fret saws excel in detailed work, while coping saws provide versatility in common power jig applications.

Choosing the Right Saw Makes All the Difference

When choosing between a fret saw and a coping saw, remember that “measure twice, cut once.” You’ll want the fret saw for intricate, delicate cuts thanks to its thin blade and deeper throat, while the coping saw suits general woodworking with its sturdier blade and versatility.

Understanding their blade thickness, frame design, and tensioning will help you maintain precision and efficiency. Pick the right saw to match your project’s needs, and you’ll save time and frustration.

- Fret saw with frame made of flat, plated steel.

- Orange-lacquered beechwood handle.

- Fitted with a blade for wood working.

- MULTI-PURPOSE COPING SAW. BLADE REPLACEABLE TYPE: An easy-to-use saw with replaceable blades. It…

- DEEP FRAME DESIGN FOR A VARIETY OF TIMBER: Since the frame has a depth of 6.3″ (160 mm), you can cut…

- EASY INTERCHANGEABLE STYLE: No special tools (wrenches or screwdrivers ) are required to replace the…

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API