Do You Need an Electric Brake on a Circular Saw: Behind the Reasons

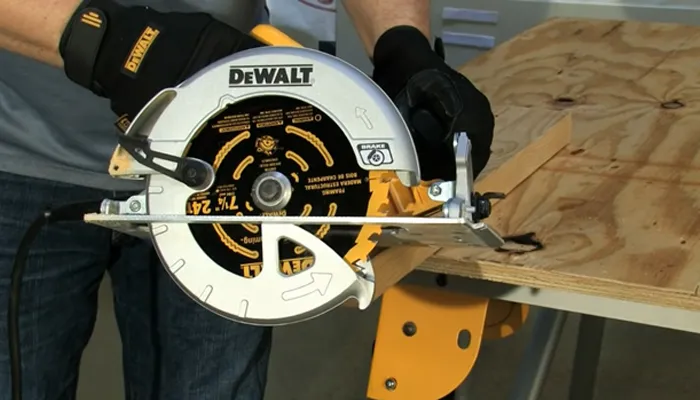

Circular saws are versatile and indispensable tools in the world of construction, woodworking, and DIY projects. However, they come with inherent risks, mainly due to the blade’s spinning nature, which continues even after the trigger is released.

To address this safety concern, electric brakes have become an indispensable feature in modern circular saws. And I believe you also need one.

Electric brakes ensure safety during operation by quickly stopping the blade once you release the trigger, reducing the risk of accidents. Stopping the blade’s rotation instantly prevents kickback, which occurs when the blade catches on material and forcefully jerks the saw back toward the user.

Here, I’ll discuss the reasons for using a circular saw with an electric brake and whether it’s suitable for various applications. I’ll also discuss whether these saws require any special maintenance.

Why Do You Need an Electric Brake on a Circular Saw?

According to my research, electric brakes are one of the most important safety features of left or right hand circular saws. Here are some of the reasons why you should get one:

- Safety during operation

- Overheating prevention

- Enhancing precision and quality

- Noise reduction

- User-friendly and time-saving

- Operator confidence and reduced fatigue

No 01. Safety During Operation

The electric brake in a circular saw is a crucial safety feature that rapidly stops the blade’s rotation when the trigger is released, preventing accidents and injuries. This feature is particularly useful when cutting various materials with powerful saws, as it prevents the blade from continuing to spin after the cut is complete.

In kickback cases, the blade is forced to move backward due to pinching or resistance during cutting. The electric brake can prevent this from happening. By instantly stopping the blade’s rotation, the electric brake minimizes the risk of injuries associated with kickback, helping operators maintain control over the saw.

Additionally, circular saws are safer to use with the electric brake, especially in busy workplaces where distractions and human errors are a possibility. Whether you choose a left handed circular saw or a right-handed one, I recommend investing in a saw that has an electric brake.

No 02. Overheating Prevention

To prevent overheating and maintain optimal cutting performance, an electric brake is necessary on a circular saw. During prolonged use, the friction between the circular saw blade and the material being cut generates heat.

This heat can cause the blade to expand, leading to a decrease in cutting efficiency and potentially damaging the material being cut.

Moreover, an overheated blade increases the risk of accidents due to its reduced effectiveness and the potential for it to cause burns or injuries upon contact. An electric brake quickly stops the blade rotation when the trigger is released, dissipating the heat and preventing further overheating.

I believe this not only ensures that the blade stays at its optimal temperature but also minimizes the risk of accidents caused by a hot and spinning blade.

No 03. Enhancing Precision and Quality

When using a circular saw, having an electric brake enhances the precision and quality of cuts by quickly stopping the blade rotation. It eliminates the risk of after-cut blade rotation that can lead to splintering or uneven edges.

This feature is especially important in carpentry and fine woodworking, where clean and precise cuts are crucial.

The electric brake applies an electric current to the motor, causing it to reverse polarity and rapidly stop the blade’s rotation. This almost instant stop allows for more accurate cuts, as it prevents any movement of the blade after the cut is made.

Using this rapid stopping action keeps the blade from forcefully jerking back, making various circular saws safer to operate.

No 04. Noise Reduction

When the operator releases the trigger, the electric brake rapidly stops the spinning blade, minimizing residual noise. This feature is particularly beneficial when working in enclosed or noise-sensitive spaces where excessive noise can be disruptive or even damaging to hearing.

A circular saw with an electric brake reduces the noise generated by the saw, improving the operator’s overall comfort and productivity.

Additionally, the electric brake creates a quieter working environment, providing a more pleasant and conducive environment for you.

No 05. User-Friendly and Time-Saving

An electric brake on a circular saw improves user-friendliness and saves valuable time. When using a circular saw without an electric brake, it can take up to 12 seconds for the blade to stop completely after releasing the trigger.

This can be frustrating and time-consuming, especially for professionals who rely on efficient and productive work processes.

However, with the addition of an electric brake, the blade stops within a few seconds, typically around 2 seconds. This significant reduction in stopping time allows users to quickly move on to the next cut, increasing overall productivity.

Additionally, the user-friendly nature of an electric brake makes it easier for operators to control the saw and ensures a safer working environment.

No 06. Operator Confidence and Reduced Fatigue

Adding an electric brake on a circular saw significantly boosts your confidence as an operator, reducing fatigue and ensuring a safer work experience. With the ability to stop the blade instantly, you no longer have to worry about the blade spinning out of control or accidentally cutting into something you didn’t intend to.

This increased level of control and safety allows you to focus more on the task at hand and less on potential hazards.

Additionally, the electric brake helps to reduce fatigue by eliminating the need to stop the blade manually after each cut. This not only saves time but also reduces strain on body muscles, allowing you to work for longer periods without feeling as tired.

Are circular saws with electric brakes suitable for various applications?

I realized that circular saws with electric brakes are versatile and can be used for cutting plywood, framing walls, exterior finishing, and more. This makes them adaptable to a wide range of construction and woodworking tasks.

Do circular saws with electric brakes need maintenance?

Regarding maintenance, circular saws with electric brakes require regular attention to ensure optimal performance and safety. While electric brakes don’t need as much maintenance as their traditional counterparts, they still require some care to keep them in good working condition.

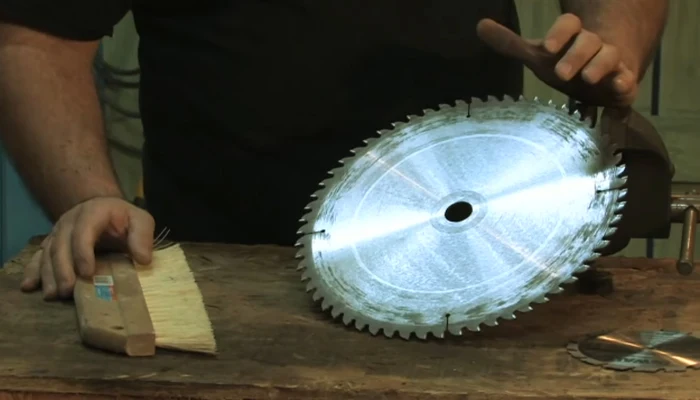

One important maintenance aspect is regularly checking the brake pads for wear and tear. Over time, the brake pads can become worn and less effective, which can compromise the safety of the saw.

If the brake pads are worn, I recommend replacing them promptly to maintain the saw’s braking ability to prevent accidents and injuries.

Make sure your blades are sharpened as well. Keep your circular saw blades sharp by using a circular saw blade sharpener.

Circular Saws with Electric Brakes: Stay Safe and Efficient

Having an electric brake on a circular saw is essential for safety and efficiency. It allows for quick stopping of the blade, reducing the risk of accidents. Circular saws with electric brakes are versatile and suitable for various applications, making them a valuable tool for professionals and DIY enthusiasts alike.

While these saws may require maintenance, their benefits outweigh any extra effort. It is important to check the brake pads regularly for wear and tear, as worn brake pads can reduce the braking ability of the saw. So, invest in a circular saw with an electric brake to enhance your woodworking experience.