Can You Cut Wood With a Metal Bandsaw: Find Out The Process

Many woodworkers have wondered whether they can cut wood with a metal bandsaw. It’s obvious that a metal cutting bandsaw is more robust than one designed to cut wood, but can you use these bandsaw blades to cut wood precisely?

Well, let me tell you, metal cutting bandsaws are typically built more solidly than saws designed for cutting wood. This means that the machine itself should be able to handle the task without any issues. However, the blade is where things can get a bit tricky.

Wood fibers can clog the teeth of a metal blade more quickly than metal particles because of the slower FPM. As part of this article, I’ll explain how to cut a wood block with a metal cutting bandsaw. I’ll also discuss what factors to consider when cutting.

How Do You Cut Wood With a Metal Bandsaw?

I have listed 5 key steps you must follow to cut wood successfully with a metal cutting bandsaw.

- Blade selection

- Machine preparation

- Implementing the bandsaw blade

- Execute the cutting technique

- Post-cut cleanup

Step 1: Blade Selection

For cutting wood with a metal bandsaw, I recommend selecting a 6-TPI metal-cutting blade. With its finer teeth, this blade is designed to handle wood fibers without clogging, resulting in cleaner and smoother cuts.

The 6-TPI blade’s teeth-per-inch ratio strikes the right balance between cutting efficiency and wood fiber clearance. With this blade, you can achieve precise and accurate cuts, minimizing the chances of splintering or chipping.

Step 2: Machine Preparation

After selecting the appropriate blade, prepare the machine for cutting wood on a metal bandsaw by following these steps.

First, ensure that the bandsaw is properly adjusted for wood cutting. This includes setting the blade tension, tracking, and guide bearings. The blade tension should be adjusted to the manufacturer’s recommended specifications, ensuring it’s neither lost nor tight.

Next, check the blade’s tracking, ensuring it runs smoothly on the wheels without any wobbling or slipping. Lastly, inspect and adjust the guide bearings, ensuring they’re positioned correctly to support the blade during cutting.

Step 3: Implementing the bandsaw Blade

After properly adjusting the machine for wood cutting, begin by installing the bandsaw blade. With a 6TPI configuration, this specific blade choice balances speed and precision, making it ideal for wood-cutting tasks on a metal bandsaw.

To ensure proper installation, carefully follow the manufacturer’s guidelines for my bandsaw model. This includes securely fastening the blade onto the bandsaw’s wheels and applying appropriate tension.

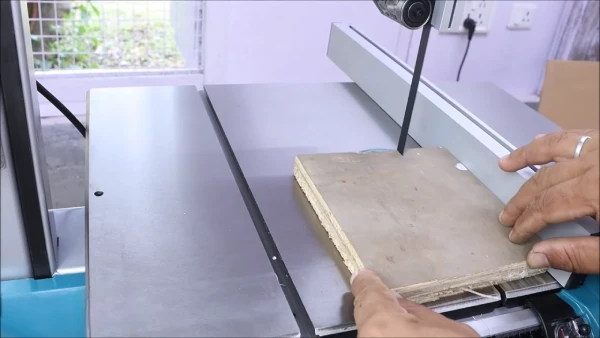

Step 4: Execute the Cutting Technique

A steady and patient cutting technique must be employed to achieve successful wood cutting with a metal cutting bandsaw blade. Maintaining a consistent feed rate is crucial, allowing the blade to cut through the wood smoothly.

Start by positioning the wood securely against the fence and aligning it with the blade. Slowly lower the blade onto the wood, ensuring the teeth engage properly. Apply gentle pressure and let the blade work, avoiding forcing or excessive pushing.

Step 5: Post-Cut Cleanup

Maintaining cleanliness is essential for properly keeping a metal bandsaw when cutting wood. After completing the woodcutting process, conduct a thorough post-cut cleanup to ensure the longevity of your bandsaw and maintain a clean working environment.

Switch off the bandsaw and unplug it from the power source to prevent accidents. Remove any wood chips, sawdust, or debris from the work area using a brush or a vacuum cleaner. Pay close attention to the areas prone to buildup, such as the blade guides, wheels, and table surface.

What to Consider When Cutting Wood With a Metal Bandsaw?

Several important factors must be considered when cutting wood with a bandsaw for metal cutting.

1. Machine Cleanliness

I always advise ensuring the metal bandsaw is clean before cutting wood, as wood particles can mix with the oils and lubricants used in metalwork. There are a few key considerations to keep in mind when it comes to machine cleanliness.

After each cut, clean the bandsaw’s work surface and remove any wood debris that may have accumulated. This can be done using a brush or vacuum cleaner designed for woodworking equipment.

Additionally, inspect and clean the blade guides and the blade itself to prevent any buildup of wood particles or sawdust.

2. Machine Speed

To ensure optimal performance when cutting wood with a metal bandsaw, it’s important to consider the machine’s speed. Adjusting the bandsaw’s speed (1000 FPM) to match the wood-cutting requirements is crucial. Slower speeds are often preferable for wood as they help achieve smoother cuts.

To determine the appropriate speed, consult the bandsaw’s manual, which guides adjusting the speed based on the wood’s type and thickness. The manual will also specify the range of speeds available on the bandsaw and the corresponding cutting applications.

3. Blade Lubrication

Consider blade lubrication with a metal bandsaw to ensure smooth and efficient wood cutting. Using a lubricant specifically designed for wood cutting on metal bandsaws can greatly improve the saw’s performance and extend the blade’s life.

The lubricant helps reduce friction between the blade and wood, resulting in less heat generated during cutting. However, remove excess lubricant as it can cause the blade to become clogged and prevent it from working properly.

4. Material Clamping

Material clamping is a critical aspect of the cutting process as it ensures the wood remains stable and secure during the operation. To achieve this, there are several factors to consider.

- The clamping device should be strong enough to hold the material firmly in place, preventing any movement that could result in inaccurate cuts.

- The clamping pressure should be evenly distributed across the wood surface to minimize the risk of warping or bending.

- The clamping mechanism should be easily adjusted to accommodate different wood sizes and shapes.

- Regularly inspect and maintain the clamping device to ensure its effectiveness and prevent potential safety hazards.

How thick of wood can a metal bandsaw cut?

A metal bandsaw can cut wood to a certain thickness, depending on its size and power. Many smaller bandsaws can cut through lumber up to 4 inches thick, while larger saws can handle cuts up to 6 inches thick. The maximum cutting capacity may vary depending on the specific model and manufacturer.

The type of wood being cut can also affect the cutting thickness. Harder woods may require more power and a slower cutting speed to achieve clean and accurate cuts. Therefore, consider the specifications and capabilities of the metal bandsaw before attempting to cut thicker pieces of wood.

What speed do you need to cut wood on a metal bandsaw?

While a common speed for a bandsaw is around 1,000 feet per minute, cutting wood at higher speeds, up to and over 5,000 feet per minute is possible.

However, metal bandsaws are generally safer when you’re cutting wood slowly. Cutting wood at higher speeds can increase the risk of accidents or damage to the wood.

Keeping the speed slower can ensure better control over the cutting process and reduce the likelihood of mistakes or mishaps.

Will cutting wood on a metal bandsaw damage the machine?

Cutting wood on a metal bandsaw can damage the machine if proper precautions aren’t taken. While metal bandsaws are designed to handle the rigors of cutting metal, they can also be used to cut wood effectively.

However, note that wood particles and sawdust can accumulate in the machine if not cleaned promptly. These particles can clog the blade, affect the machine’s performance, and even cause damage to the internal components.

Unleash the Power of Your Metal Bandsaw for Wood Cutting

Cutting wood with a metal bandsaw is possible and can be done effectively. However, I recommended considering the thickness of the wood and adjusting the speed accordingly to ensure clean and precise cuts.

While it may seem daunting, cutting wood on a metal bandsaw won’t damage the machine if proper precautions are taken. So, unleash the power of your metal bandsaw and witness its remarkable versatility in tackling wood-cutting tasks.

It’s like having a lumberjack’s dream tool at your fingertips.