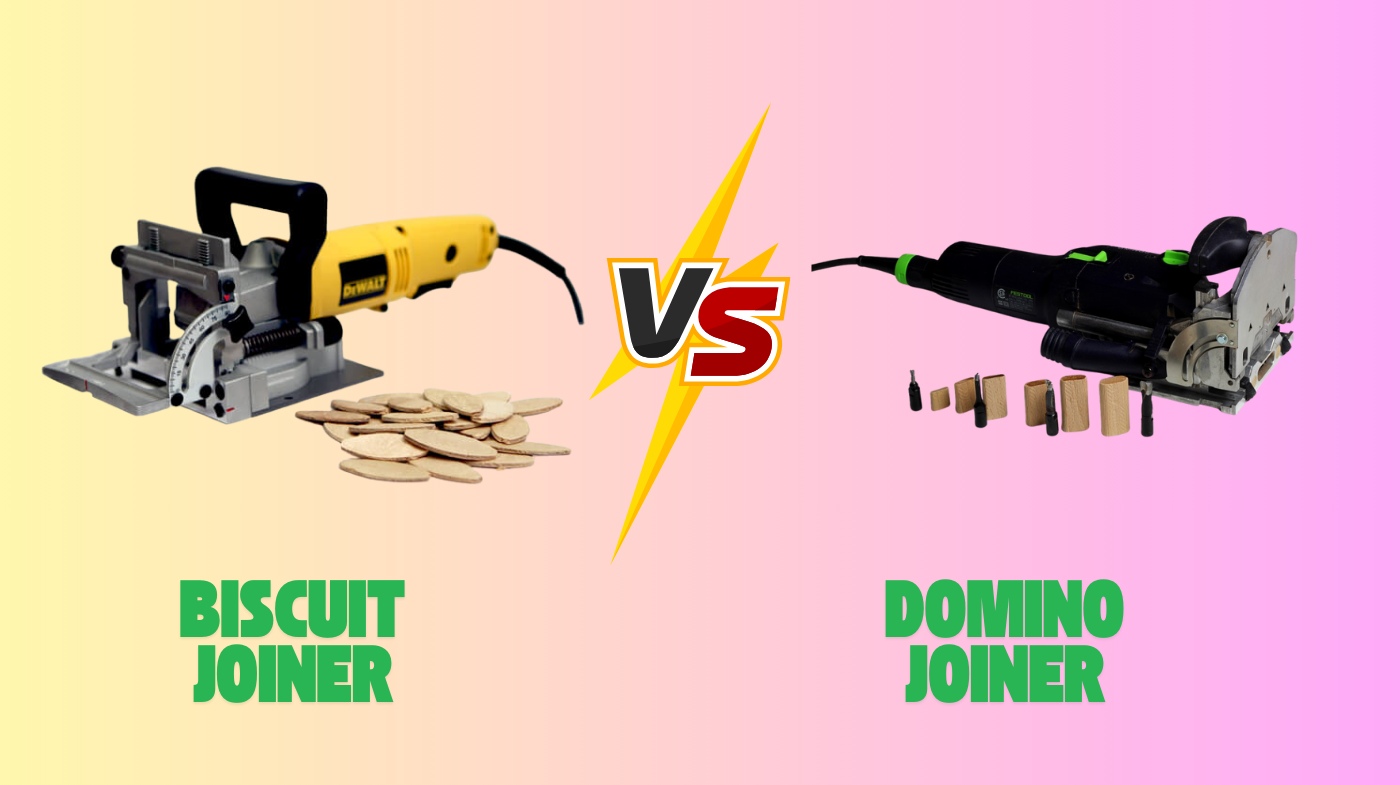

Biscuit Joiner vs Domino: Which Is Stronger for Woodworking?

If you need quick, cost-effective joints for light to medium projects, a biscuit joiner offers ease and consistency with minimal setup. But if you’re working on heavier, thicker stock requiring superior strength and precise, adjustable tenons, the domino joiner outperforms biscuits by creating deeper, stronger joints and handling complex angles.

Dominos demand a higher investment and more calibration but boost workflow efficiency for professionals. Explore further to see which tool fits your project demands best.

- Perfect for edge-joining panels, aligning boards, strengthening joints, and more

- Adjustable fence helps create biscuit slots at any height or angle

- Pre-set stops easily adjust to create slots for standard #0, #10, and #20 biscuits

- NOTE: The DF 500 only come with the 5MM cutter which is installed.

- Unique, patented cutting action that rotates and oscillates to create perfect, clean, and repeatable…

- Mortise width adjustment with the turn of a dial allows for easier alignment when joining panels.

Key Takeaways

- Domino joiners create deeper, larger tenons offering superior joint strength and durability compared to the shallower, oval-shaped biscuit joints.

- Biscuit joiners are faster and easier to use with lower costs, ideal for small to medium projects and quick edge or miter joints.

- Domino joiners handle thicker, denser materials and complex angles, making them suitable for heavy-duty, professional woodworking applications.

- Biscuit joiners provide consistent slot alignment and quick setup, best for repetitive tasks and hobbyist woodworking.

- Domino joiners require higher initial investment and maintenance but offer better precision, versatility, and long-term joint reliability.

Key Differences Between Biscuit Joiners and Domino Joiners

| Feature / Aspect | Biscuit Joiner | Domino Joiner |

|---|---|---|

| Joint Strength | Moderate; relies mostly on glue | Superior; loose mortise and tenon for load-bearing joints |

| Precision & Accuracy | Excellent for slot alignment; easy setup | High precision with adjustable mortise width and depth |

| Material Thickness | Works best up to 1.5 inches | Handles thin to very thick stock efficiently |

| Joint Types Supported | Edge, butt, and miter joints | Corner, frame, miter, end-grain, and complex angles |

| Ease of Use | Beginner-friendly; fast setup | Requires skill; advanced reference points for accuracy |

| Project Size Compatibility | Small to medium projects | Small to large-scale projects, including structural pieces |

| Maintenance & Consumables | Low; standard blades and biscuits | Higher; specialized cutters, calibration, and dust management |

| Versatility | Limited by fixed biscuit sizes | Multiple tenon sizes, adjustable mortises, high adaptability |

| Workflow Efficiency | Quick repetitive tasks | Faster for complex joinery after setup; reduces rework |

| Durability & Longevity | Suitable for non-structural work | High durability; maintains strength under heavy use |

Comparison of Joint Strength and Structural Integrity

When you compare joint strength and structural integrity, domino joiners clearly outperform traditional biscuit joiners due to their loose mortise and tenon design.

Domino joints create rectangular mortises that fit larger, thicker tenons, enabling deeper insertion and superior load distribution. This design reduces localized stress and minimizes joint slop, maintaining integrity under repeated or heavy loads. The precision of the mortise cuts aligns with high-performance cutting tools to ensure accuracy and fit.

In contrast, biscuit joints rely heavily on glue strength and offer less resistance to shear and tensile forces, often degrading faster under mechanical stress. The square-edged slots cut by domino joiners ensure a firmer seating of tenons, limiting rotational movement and increasing durability. Additionally, biscuit joiners are versatile for edge-to-edge joints, making them suitable for lighter woodworking tasks.

Additionally, the denser beech or mahogany material of dominos enhances resilience compared to composite biscuits. For structural applications demanding high stability, domino joinery provides a more robust, reliable connection than traditional biscuit joinery.

Precision and Accuracy in Joinery

Although both biscuit and domino joiners aim to produce strong joints, biscuit joiners excel in precision and accuracy through consistent slot alignment and adjustable depth settings.

Biscuit joiners offer superior precision with consistent slot alignment and adjustable cutting depths.

You rely on uniform, arc-shaped slots and reference edges on the tool base to maintain exact datum points for each cut. Adjustable slot depth matches biscuit thickness, ensuring a snug fit and reducing joint play. Using proper lubrication on the blades can help maintain cutting efficiency and prolong tool life.

Proper clamping and clear marking minimize movement and error, while controlled biscuit swelling after glue-up compensates for minor imprecisions without masking poor technique. Biscuit joiners also facilitate fast and visually appealing wood joints, enhancing workflow efficiency.

Versatility and Application Range

When selecting between a biscuit joiner and a domino, consider the joint types you need—biscuits handle edge and miter joints well, while dominos excel in loose tenons for complex angles. Ensuring accurate cuts also depends on the alignment of your tools and workpieces. Your project size also matters; biscuits suit small to medium works, whereas dominos adapt to larger, more demanding assemblies.

Additionally, material thickness affects tool choice, with dominos accommodating thicker stock and denser woods more effectively. Before cutting, it is important to mark alignment lines across wood pieces for precise biscuit placement.

Joint Types Supported

Since joint strength and versatility often dictate the choice of joinery tools, understanding the joint types supported by biscuit and domino joiners is essential.

Biscuit joiners excel at quick edge alignment with shallow, oval biscuits, but their limited depth restricts glue surface and joint strength. Regular maintenance and proper technique ensure optimum performance and durability of biscuit joints.

Domino joiners create deep, adjustable mortises for rectangular tenons, mimicking traditional mortise-and-tenon joints and offering superior strength and precision across various joint types.

Consider these distinctions:

- Domino joiners provide strong corner, frame, and miter joints with adjustable mortise sizes.

- Biscuits mainly support basic edge and butt joints with fixed sizes.

- Domino’s capability for deep end grain joints ensures durability where biscuits fall short.

- Variable tenon sizes on domino joiners adapt precisely to material thickness and joint demands.

- Additionally, domino joiners are compatible with a wide range of cutter sizes and tenon thicknesses, enhancing their versatility and compatibility across different woodworking projects. Proper tool upkeep, similar to sharpening chainsaw chains with correct filing techniques, is crucial for maintaining joint accuracy and tool longevity.

Project Size Compatibility

Understanding the joint types each tool supports naturally leads to contemplating how they perform across different project sizes. Domino joiners accommodate a wide range, from delicate 5/16-inch components to large structural pieces like doors and tables.

Their adjustable tenons enable precise, angled, and strong joints, essential for complex or heavy-duty applications. The Domino offers narrower floating tenons usable on narrower stock, enhancing its flexibility for various project dimensions and materials floating tenons.

In contrast, biscuit joiners offer fixed 4mm-thick biscuits in three sizes, suiting mostly small to medium projects like cabinetry and frames. While biscuits are cost-effective and user-friendly, their limited size and weaker glue area restrict use in large or structural work. Retrofitting safety features like SawStop involves complex structural modifications that are often impractical for standard biscuit joiners.

Domino’s larger models, such as the XL DF700, excel where strength and repeatability are critical. Ultimately, you’ll find biscuits adequate for simpler tasks, but Domino joiners provide unmatched versatility and robustness across the project size spectrum.

Material Thickness Handling

Although both biscuit and Domino joiners serve to create strong joints, their ability to handle varying material thicknesses differs considerably.

Domino joiners excel with a thickness range from 5/16 inch to several inches, offering multiple cutter sizes for precise mortises and deep penetration. Their adjustable mortise width allows fine-tuning the joint fit to accommodate expansion or slight misalignments in material thickness. This versatility is enhanced by maintaining safety precautions when adjusting and operating the tool.

Biscuits, limited by fixed thickness and shallow cuts, suit materials thicker than 1-1/2 inches but falter with thin or heavy stock.

When you need versatility, consider:

- Dominos cut mortises as shallow as 12mm and as deep as 28mm, ideal for thin or thick panels

- Biscuits penetrate only about 12mm, restricting use on very thin or thick materials

- Large Domino cutters enable structural joints in heavy stock beyond biscuit capacity

- Dominos provide superior joint strength and adaptability across diverse thicknesses

Speed and Ease of Use for Woodworkers

When you need to quickly set up for common joint sizes, biscuit joiners require fewer adjustments, letting you start work faster. Their fixed blade size and minor depth tweaks simplify preparation, making them ideal for rapid, repetitive tasks like panel alignment.

This makes biscuit joiners particularly cost-effective tools for hobbyists and casual woodworkers. Additionally, biscuit joiners can be paired with simple jigs to further enhance cutting consistency without complex setup.

Domino joiners, however, offer adjustable mortise width and depth, plus multiple cutter sizes, adding setup time but enabling precise joint customization. While Domino tools demand a steeper learning curve and careful placement, they reward you with stronger, more accurate joints and reduced clamping time. Their versatility can be likened to the adjustable miter saw, providing the ability to handle complex angles and precise adjustments in woodworking.

Biscuit joiners excel in straightforward edge alignment with minimal measurement, making them more forgiving for beginners. In contrast, Domino joiners speed workflow on complex or varied joinery once you’ve mastered their advanced settings and setup requirements.

Tool Features and Adjustability Differences

When comparing biscuit joiners and dominoes, you’ll notice key differences in mortise width adjustability and depth ranges that affect joint strength and versatility. Proper tool maintenance, including blade tension management, is essential to ensure consistent and accurate cuts with either tool.

Biscuit joiners accommodate multiple biscuit sizes with fixed cutter widths. Domino joiners, on the other hand, offer variable mortise dimensions tailored to different domino sizes. Additionally, biscuit joiners often feature an adjustable depth setting to ensure precise joinery for various project needs.

Mortise Width Adjustability

Although both biscuit joiners and DOMINO tools create mortises for joinery, the DOMINO offers superior mortise width adjustability that directly enhances joint fit and flexibility. You’ll find DOMINO mortises adjustable via a rotary switch, letting you select preset widths (13, 19, 23 mm) plus cutter diameter, and fine-tune width up to +6 mm per side.

Biscuit joiners, however, cut fixed-width slots matched only to biscuit sizes (#0, #10, #20), lacking this nuanced control.

With DOMINO, you gain:

- Precise mortise width control for ideal joint tightness

- Multiple width presets plus incremental adjustments

- Digital display feedback for repeatable settings

- Flexibility to match loose tenon thickness and clearance needs

This adjustability gives DOMINO a clear edge in adaptable, precise joinery. Proper tool maintenance, including cleaning and lubrication, ensures consistent mortise quality and tool longevity, which is critical for reliable joinery performance and avoiding bandsaw maintenance issues.

Depth Adjustment Range

While biscuit joiners typically rely on preset depth stops calibrated for standard biscuit sizes, their adjustability remains limited compared to Domino joiners. You’ll find three main preset depth settings aligned with common biscuit sizes (#0, #10, #20), selectable via a rotating knob that clicks into place for repeatability.

Fine tuning beyond these stops is possible on some models using jam nuts or screws, allowing adjustments of roughly ±2-3 mm. Advanced biscuit joiners like the DeWalt DW682 offer fine depth screws for incremental control around 1 mm per turn, accessed by raising the fence.

It is important to note that the depth of cut should be slightly deeper than half the width of the biscuit for a proper fit, typically around 10mm for #10 biscuits and 13mm for #20 biscuits, ensuring optimal joint strength.

Depth markings are clear and controls ergonomically placed for ease during operation. This setup suits typical material thicknesses, balancing joint strength and fit, but lacks the micrometer-level precision and digital scales found on Domino joiners.

Cutter and Biscuit Sizes

Because the cutter size directly influences joint strength and application scope, understanding the differences between Domino and biscuit joiner cutters is essential.

Domino cutters range from 4 to 14 mm thick tenons, offering greater lateral strength with a consistent 25 mm mortise width. Biscuit joiners cut shallower slots for smaller biscuits, typically 4–7 mm wide, limiting joint robustness.

When choosing between them, consider:

- Domino’s adjustable cutters suit fine craft to heavy furniture, enhancing joint durability.

- Biscuit joiners offer quick, simple size swaps between biscuits 0, 10, and 20.

- Domino’s deeper cuts enable stronger tenon engagement, ideal for cabinetry. The Domino DF700 model can cut mortises up to 70mm depth, allowing for more substantial joinery in demanding projects.

- Biscuit joiners prioritize speed and alignment over structural strength.

Performance on End Grain and Difficult Materials

When working with end grain or challenging materials, you’ll find that Domino joiners deliver superior joint strength and precision compared to biscuit joiners.

Domino’s mortise and tenon joints engage wood fibers deeply, creating stronger bonds on end grain where biscuits fail due to their flat, oval shape. The Domino’s adjustable mortise depth and smaller tenon sizes enhance versatility, especially for narrow or dense hardwood pieces.

When handling hardwoods, plywood, or MDF, the Domino cuts clean, precise mortises with consistent sizing, minimizing tear-out and ensuring stronger joints. The strength of joints depends heavily on glue application, joint design, and proper technique rather than solely on the tool used, reinforcing the importance of glue and technique.

Biscuits work well for alignment on veneered or less dense materials but offer weaker mechanical strength and less reliable fit in stress applications.

Impact on Project Efficiency and Workflow

Although both biscuit and Domino joiners serve to align and strengthen joints, you’ll find that Domino joiners considerably enhance project efficiency through faster setup, fewer adjustments, and streamlined workflow. Their variable mortise sizes and precision reduce the need for multiple passes, while guided placement eliminates tedious manual marking.

Biscuit joiners suit quick, simple tasks but can slow you down with extra measurements and limited joint options. They are also cost-effective and accessible, making them popular for casual or budget-conscious woodworkers.

Choosing Domino joiners means you benefit from:

- Reduced setup and alignment time, accelerating project completion

- Versatility in joint types and timber thicknesses for complex assemblies

- Stronger joints minimizing rework and downstream delays

- Tool consolidation, simplifying workflow and reducing equipment changes

Suitability for Hobbyists vs Professional Woodworkers

You’ll find biscuit joiners easier to operate with minimal setup, making them ideal for hobbyists who prioritize simplicity and lower investment.

On the other hand, Domino joiners demand a higher upfront cost and more skill but offer superior durability and precision suited for professional workflows.

Ease of Use

Since ease of use directly affects workflow efficiency and learning curve, selecting between a biscuit joiner and a Domino joiner hinges on your woodworking experience and project demands.

Biscuit joiners feature minimal setup with straightforward depth and fence adjustments, ideal if you want quick, reliable results without complexity.

Domino joiners, however, offer advanced reference points and customizable settings, demanding more familiarity but rewarding you with precision and repeatability ideal for professionals.

Consider this when choosing:

- Minimal setup and simpler operation for immediate use

- Advanced indexing and slot customization for complex joints

- Faster blade changes on biscuit joiners versus nuanced cutter swaps on Domino

- Enhanced workflow speed in volume tasks with Domino’s guided systems

Investment and Durability

When evaluating investment and durability, you must weigh the upfront costs against long-term value and tool longevity. Biscuit joiners offer a lower entry price and simpler maintenance, ideal for hobbyists focused on occasional, alignment-based tasks. Their composite wood biscuits provide sufficient strength for non-structural applications but lack longevity under heavy use.

Conversely, Domino joiners demand a higher initial outlay and ongoing investment in varied cutters but deliver superior precision and robust tenon joints crafted from hardwood. Professionals benefit from Domino’s durable build, designed for continuous workshop demands, and its ability to reduce labor and material waste over time.

If your work requires structural integrity and repeatability, Domino’s advanced features justify the cost. For casual or infrequent projects, biscuit joiners remain cost-effective without compromising basic functionality.

Maintenance and Consumable Costs

Although both biscuit and domino joiners require regular maintenance and consumable replacements, their costs and complexities differ markedly. Biscuit joiners boast simpler upkeep with fewer moving parts and readily available, affordable blades. Biscuit joiners typically use carbide-tipped blades that are heat-resistant and durable, contributing to their lower maintenance needs.

Domino joiners demand precise calibration and use specialized, pricier cutters, raising consumable costs. Both tools need blade cleaning and replacement, but domino’s quick-change system offsets some complexity.

Consider these factors:

- Biscuit joiner blades last hundreds of cuts and fit standard sizes, easing budgeting.

- Domino cutters, although costly, provide versatile mortise dimensions.

- Maintenance on biscuit joiners can involve stuck arbor screws needing specialty lubricants.

- Domino joiners require routine calibration and dust removal to preserve precision.

Frequently Asked Questions

Can Biscuit or Domino Joiners Be Used for Outdoor Furniture Projects?

You can use both joiners for outdoor furniture, but you’ll want to be cautious. Standard wood biscuits absorb moisture, swell, and rot over time, making them unreliable for structural joints outside.

Domino joiners create stronger mortise-and-tenon joints that withstand environmental stresses better.

If you choose biscuits, use waterproof glue and sealants, but for durability and strength, especially under load, Domino joinery with proper adhesives and weather-resistant wood is your best bet.

Are There Safety Concerns Unique to Biscuit or Domino Joiners?

You’ll face similar core safety concerns with both tools: electrical risks, sharp cutter blades, and dust inhalation hazards.

However, domino joiners often have larger, more powerful motors and deeper cuts, increasing kickback potential and requiring firmer workpiece securing. You must examine cords, wear proper PPE, and control blade depth before starting.

Always keep hands clear of blades, maintain stable material positioning, and ensure proper ventilation to minimize vibration and dust-related injuries.

How Do Biscuit and Domino Joiners Affect Wood Finishing Processes?

You know what they say: “Measure twice, cut once.” When finishing wood, precise joinery matters. Biscuit joints create slight surface tension needing light sanding, while domino joints cut cleaner mortises, minimizing prep.

Domino’s superior alignment means smoother grain flow and less finishing hassle. Both rely on glue for tight fits, but dominos offer stronger, more durable surfaces that resist cracking.

You’ll find domino joints often require less filler and sanding, streamlining your finishing workflow.

Can Either Joiner Be Used Effectively on Reclaimed or Warped Wood?

You can use joiners on reclaimed or warped wood, but each has limits. Biscuit joints align edges but struggle with irregular moisture and warping, reducing tightness and strength.

Domino joiners handle irregularities better, offering stronger mechanical interlocks and more surface area for glue, which helps stabilize warped wood.

For durable, reliable joints on compromised wood, prepare surfaces carefully and favor domino joiners despite their higher cost and skill requirements.

What Are the Noise Levels During Operation for Biscuit Versus Domino Joiners?

When you run a DeWalt biscuit joiner, expect noise up to 106 decibels—like a loud rock concert.

In contrast, a Festool Domino joiner hums quieter, around 80-90 decibels, thanks to superior motor design and better vibration control.

This difference means you’ll definitely want hearing protection with biscuit joiners for prolonged use, while Domino’s gentler noise might let you work a bit longer with less ear fatigue.

Choose Between Biscuit Joiner vs Domino for Your Projects

Choosing between a biscuit joiner and a domino ultimately depends on your project needs and budget. Do you want speed and versatility with a professional edge, or a reliable, cost-effective tool for simpler tasks?

Both offer strong joints and accuracy, but the domino excels in precision and efficiency, especially on complex or end-grain work. Consider your workflow, investment, and maintenance to make the smartest choice—after all, your tool should work as hard as you do.

- 6.5 amp, 10,000 rpm motor provides power for working in the hardest woods

- Dual rack and pinion fence ensure blade and fence are always parallel for accurate joints every time

- Integral one-piece fence is adjustable and tilts 0-90°

- NOTE: The DF 500 only come with the 5MM cutter which is installed.

- Unique, patented cutting action that rotates and oscillates to create perfect, clean, and repeatable…

- Mortise width adjustment with the turn of a dial allows for easier alignment when joining panels.

Last update on 2026-02-21 / Affiliate links / Images from Amazon Product Advertising API