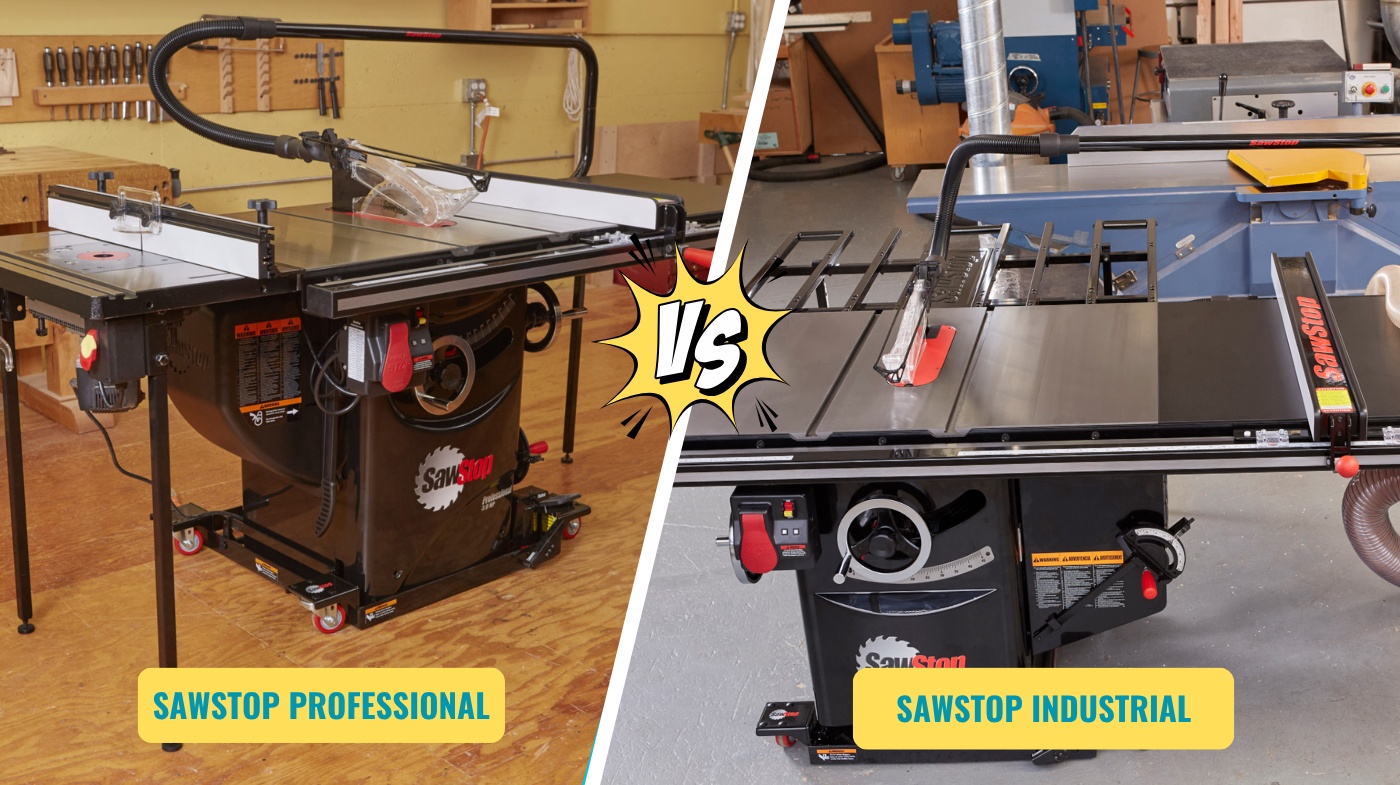

SawStop Professional vs Industrial: Key Features Compared

If you need a saw with heavy-duty power and stability, the SawStop Industrial offers 3 to 7.5 HP motors, a larger cast iron table, and robust construction ideal for demanding shop environments.

The Professional model is lighter, with 1.75 to 3 HP motors, a smaller table, and better dust collection, suited for hobbyists or smaller spaces.

Both prioritize safety, but your choice depends on workload, portability, and space. Explore the key differences to find what fits your needs best.

- 36-INCH T-GLIDE FENCE ASSEMBLY: The 36-inch T-Glide Fence & Rail are made of heavy-gauge steel for…

- SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less…

- UNMATCHED QUALITY: The trunnion and arbor are built for precision, strength and stability. The gas…

- SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less…

- RELIABILITY: The Control Box houses the on-off switch, power paddle, and on-board computer, and…

- 52-INCH T-GLIDE FENCE ASSEMBLY: The 52-inch T-Glide Fence & Rail are made of heavy-gauge steel for…

Key Takeaways

- The Industrial SawStop is over 200 lbs heavier, offering superior stability, vibration dampening, and noise reduction compared to the lighter Professional model.

- Industrial models have larger, deeper tables and beefier fence systems for enhanced precision and support of bigger workpieces.

- Motor options differ: Industrial saws feature 3-7.5 HP motors requiring dedicated circuits, while Professional saws offer 1.75-3 HP motors suitable for 120V or 220V.

- Both use SawStop’s flesh-sensing safety system, but Industrial models add lock-out switches and faster response for demanding environments.

- Dust collection is more efficient on the Professional due to integrated ports, while Industrial models have full blade shrouds with swinging access for dust capture.

Comparison Table: SawStop Professional vs SawStop Industrial

| Feature | Professional | Industrial |

|---|---|---|

| Weight | ~400 lbs | ~600 lbs (200+ lbs heavier) |

| Motor Power | 1.75-3 HP (120V/220V) | 3-7.5 HP (230V single-phase) |

| Table Size | Smaller, compact design | 3 inches deeper, larger workspace |

| Build Quality | Two-piece trunnion, lighter construction | One-piece cast iron trunnion, superior rigidity |

| Fence System | Lighter, integrated dust collection | 52-inch T-Glide, beefier rails for precision |

| Dust Collection | Superior efficiency, dedicated rear hookup | Full blade shroud, multiple ports |

| Portability | Mobile base option, easier transport | Limited mobility, workshop permanent |

| Electrical Requirements | Standard circuits (120V/220V) | Dedicated circuits required |

| Target User | Hobbyists, smaller shops | Production environments, heavy-duty use |

| Stability | Good for moderate tasks | Superior vibration dampening |

| Safety Features | Core flesh-sensing system | Lock-out switches, faster response |

Build Quality and Weight Differences

While both the SawStop Professional and Industrial models boast solid construction, the Industrial saw clearly outperforms in build quality and weight, thanks to its extensive use of iron and steel components.

You’ll notice the Industrial weighs around 600 pounds, over 200 pounds heavier than the Professional’s 400 pounds, enhancing stability and vibration dampening. This added mass also helps in reducing noise reduction during operation.

Its thicker, deeper cast iron table and one-piece trunnion casting provide robust, rigid support for precise blade movement. The Industrial’s heavier fence rails and larger blade guard improve fence accuracy and safety.

In contrast, the Professional’s lighter weight favors portability but compromises some sturdiness. Additionally, the Industrial’s bolted-down insert and industrial-grade motor parts reflect a design optimized for heavy-duty, prolonged use, while the Professional targets advanced hobbyists with a more compact footprint.

The Industrial’s larger table size also offers more workspace, making it better suited for production or demanding environments.

Comparison of Table Size and Fence Systems

The Industrial saw’s heavier build and larger footprint naturally extend to its table and fence systems, which are designed to handle bigger, more demanding projects.

Its table is 3 inches deeper than the Professional’s, offering enhanced support for large workpieces. This additional depth also allows for better workpiece stability during extended cutting operations.

The 52-inch Industrial T-Glide fence features beefier rails for superior rigidity and mechanical engagement, ideal for precision and durability in industrial settings. In contrast, the Professional model’s smaller table saves weight and space, balancing compactness with robustness.

Its fence system, while lighter and smaller, integrates improved dust collection and smoother adjustments, catering to mixed-use environments.

Both tables have flat, durable surfaces, but the Industrial’s larger size demands more workshop space, whereas the Professional’s design suits moderate-sized shops prioritizing workflow and dust control.

The weight of these systems varies significantly, with configurations ranging from 635 to 685 lbs, which is critical for setup and mobility considerations.

Motor Power Variations

Because motor power directly affects cutting capacity and operational demands, understanding the variations between SawStop Professional and Industrial cabinet saws is essential.

The Professional line offers 1.75 HP or 3 HP TEFC motors, operable at 120V or 220V, balancing power with typical workshop energy constraints. Proper blade height adjustment ensures optimal cutting performance with these motor options.

In contrast, Industrial models provide 3 HP, 5 HP, and 7.5 HP TEFC motors running at 230V single-phase, designed for continuous heavy-duty use and higher current draws.

This power increase allows Industrial saws to cut thicker, denser materials and handle demanding accessories like dado blades without stalling.

Also, motor power impacts electrical requirements; Industrial motors often need dedicated circuits due to higher amperage.

Choosing between these depends on whether your work demands precision and moderate power or sustained, high-capacity cutting performance.

Additionally, SawStop saws incorporate a patented SawStop Safety System that instantly halts the blade on skin contact, ensuring user protection across both Professional and Industrial models.

Safety Features and Dust Collection Efficiency

You’ll find both SawStop models share the core flesh-sensing safety system, but the Industrial saw adds advanced features like lock-out switches for maintenance security.

Additionally, the Industrial model’s safety system can stop the blade within 5/1000 of a second, offering rapid response to potential injuries safety system speed. This enhanced safety is complemented by SawStop’s patented technology, which is unique among cabinet saws.

When it comes to dust collection, the Professional model outperforms with its dedicated rear dust hookup and superior fine dust capture. Its design also includes considerations for workshop space and layout, making it easier to maintain a clean and efficient workspace.

Safety System Comparison

Although both SawStop Professional and Industrial saws incorporate the company’s patented flesh-sensing safety system that halts the blade instantly upon skin contact, they differ especially in design and dust collection features.

The Industrial model boasts a one-piece, solid cast trunnion offering superior rigidity and durability, reducing maintenance and alignment issues after brake activation.

In contrast, the Professional uses a two-piece trunnion connected by a rod, raising concerns about long-term mechanical stability under repeated stress. The Industrial also tends to be heavier, contributing to greater stability and durability during operation.

Both feature automatic brake cartridges and integrated electrical interlocks to prevent restart post-activation.

While the Professional’s blade guard includes a built-in dust port enhancing containment, the Industrial’s larger table and fence improve stability and safety.

You should weigh the Industrial’s robustness against the Professional’s compact, user-friendly design when prioritizing safety system reliability.

Dust Collection Performance

Beyond safety mechanisms, dust collection performance plays a significant role in maintaining both a clean workspace and operator health. When comparing the Sawstop Professional and Industrial models, dust containment and efficiency hinge on shroud design and port configuration. You’ll notice:

- The Industrial model’s full blade-enclosing shroud with a swinging access piece enhances dust capture but may lag in efficiency. Higher tooth count blades tend to produce less debris, which can positively affect dust collection systems.

- The Professional’s partial shroud and integrated back dust port yield superior dust extraction in practical use.

- Industrial’s multiple ports support versatile setups, ideal for larger shops. The ability to customize dust collection setups helps maintain clean work environments.

- The Professional’s compact design eases dust collection integration and visibility.

- Overall, the Professional model demonstrates higher dust collection efficiency despite Industrial’s robust build prioritizing durability over dust control.

- It is important to note that dust collection performance depends more on the overall setup than just the size of the shroud.

Portability and Convenience Considerations

When evaluating portability and convenience between the SawStop Professional and Industrial models, weight and size differences play a crucial role.

The Industrial model is about 200 pounds heavier and features a larger, deeper table, making it less portable but more stable. The Professional model’s lighter weight and smaller table enhance mobility, especially with its integrated mobile base option.

This portability makes it ideal for professionals who need to transport their saw frequently. Dust collection is more efficient on the Professional saw, aiding convenience in smaller shops.

Fence design and blade insert mechanisms also favor easier adjustments and maintenance on the Professional model. Additionally, the Professional model includes a hydraulic lift assist, which helps reduce operator effort during blade height adjustments.

Choosing the Right SawStop for Your Workshop

How do you determine which SawStop model suits your workshop needs? Assess your workspace size, workload intensity, and mobility requirements.

Industrial models offer superior stability with over 200 pounds more weight, a one-piece cast iron trunnion, and larger tables for heavy-duty precision. Professional models favor portability and moderate tasks with lighter weight and a two-piece trunnion design.

Additionally, the Industrial model supports an Industrial Mobile Base option that enables precise positioning and handles heavier weights, further enhancing its stability and suitability for demanding environments.

Consider how handle design and ergonomics impact your comfort and control during extended use when making your choice.

| Feature | Professional | Industrial |

|---|---|---|

| Weight & Mobility | Lighter, easier to move | Heavier, more stable |

| Table Size | Smaller, fits moderate shops | Larger, supports bigger stock |

| Motor Power | Suitable for moderate use | Robust for heavy workloads |

Choose Industrial for rigorous, continuous tasks; pick Professional if flexibility and space-saving matter.

Frequently Asked Questions

Can the Professional Model Handle Cutting Hardwoods Effectively?

You can depend on the professional model to handle hardwood cutting effectively. Its 3 hp motor delivers consistent power without bogging down, making it ideal for dense hardwoods.

The robust rip fence and precise crosscut fence ensure accuracy and stability, while ergonomic adjustments let you fine-tune blade height and angle easily.

Plus, the dust collection system keeps your workspace clean, supporting smooth, professional-grade cuts every time you work with hardwood.

Are Replacement Parts Readily Available for Both Models?

You’ll find replacement parts readily available through SawStop’s official online store and authorized dealers. Both models’ parts include blades, brake cartridges, belts, and guards. Manuals help you identify the right components by model number.

Though newer Industrial models have updated electronics, upgrade kits let you modernize older Professional units.

Third-party resellers like Woodcraft and Rockler also stock parts, often with free shipping, ensuring you can maintain your saw efficiently.

How Noisy Are the Professional and Industrial Saws During Operation?

Imagine the steady hum of a powerful motor blending with the clean slice of a spinning blade. You’ll find both saws produce typical cabinet saw noise—balanced, controlled, and not overly loud.

Their sturdy cabinets and heavy cast iron components dampen vibrations, so noise stays stable. The Industrial’s heavier build might slightly soften the sound, but in your workshop, the difference won’t be striking.

Do Both Models Support Dado Blade Sets?

You can use dado blade sets on both saw models, but only with the proper SawStop dado brake cartridge. They support 8” stacked dado sets up to 29/32” thick, excluding wobble or dial-a-width types.

Non-conductive blades and those with solid-plate chippers aren’t compatible. The Professional line uses the SawStop Premium Dado Set, while Industrial models allow quick cartridge swaps for dado use, ensuring safety and precision during cuts.

What Is the Average Lifespan of the Sawstop Braking Cartridge?

Imagine a safety system that lasts indefinitely unless triggered—SawStop’s braking cartridge works just like that. You won’t find an official lifespan because it doesn’t wear out over time; it only needs replacement if it activates on skin contact.

Your Saw, Your Shield: Choose with Purpose

Choosing between the SawStop Professional and Industrial is like selecting the right armor for your craft—both protect, but one offers heavier, fortified defense while the other balances strength with agility.

Your workshop’s heartbeat depends on this choice: the Industrial’s raw power and size or the Professional’s sleek precision.

Weigh your priorities carefully—safety, space, and workflow—to guarantee your saw becomes not just a tool, but a steadfast guardian of your passion and skill.

- 36-INCH T-GLIDE FENCE ASSEMBLY: The 36-inch T-Glide Fence & Rail are made of heavy-gauge steel for…

- SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less…

- UNMATCHED QUALITY: The trunnion and arbor are built for precision, strength and stability. The gas…

- SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less…

- RELIABILITY: The Control Box houses the on-off switch, power paddle, and on-board computer, and…

- 36-INCH T-GLIDE FENCE ASSEMBLY: The 36-inch T-Glide Fence & Rail are made of heavy-gauge steel for…

Last update on 2026-01-10 / Affiliate links / Images from Amazon Product Advertising API