Why Does My Circular Saw Keep Stopping: Potential Reasons and Solutions

When working with a circular saw, one common issue that I found that many woodworkers encounter is the saw stopping frequently. As a woodworking enthusiast, I researched why a circular saw keeps stopping and discovered that it could be due to several reasons.

An improperly connected or damaged power cord is one of the top reasons why your circular saw keeps stopping. Another cause of power cuts and stops is a buildup of sawdust in the motor, which can cause overheating. Dull blades also make cutting more difficult and can lead to your circular saw stopping.

I will discuss all the reasons why the circular saw keeps stopping and possible solutions in light of my research.

Why Does My Circular Saw Keep Stopping: Causes and Solutions

My research found several reasons why your circular saw stops, including:

- Improperly connected or damaged power cords

- Sawdust accumulation in the motor

- Insufficient power or stalled/Worn motor

- Inadequate or weak battery (For cordless circular saw)

- Incorrect blade for the job

- Dull blades

- Resin accumulation

- Curved blade due to heat

- Pinching of the saw blade

- Non-straight cuts or shifting wood

- Incorrect blade depth settings

- Damaged or loose arbor

1. Improperly Connected or Damaged Power Cords

Improperly connected or damaged power cords can disrupt the flow of electricity, causing the circular saw’s motor to stop functioning.

Start by visually inspecting the power cord for any signs of wear or damage. Look for frayed areas, exposed wires, or loose connections. If you notice any of these issues, it’s important to replace the power cord immediately. Damaged cords can pose a safety hazard and may lead to electrical shock or fire.

Additionally, ensure that the power cord is securely connected to both the saw and the power source. A loose connection can result in intermittent power cuts and the saw stopping unexpectedly.

2. Sawdust Accumulation in the Motor

Sawdust accumulation in the motor can lead to overheating, which can cause the saw to stop working. Over time, sawdust can clog the motor and hinder its performance.

It’s important to clean the motor regularly to ensure optimal functionality and prevent any potential issues. To clean the motor, use compressed air or an appropriate cleaning tool to remove the sawdust. Be thorough in your cleaning, reaching all areas where sawdust may have accumulated.

3. Insufficient Power or Stalled/Worn Motor

Insufficient power or a stalled/worn motor can also cause your circular saw to stop unexpectedly. If the power supply isn’t delivering enough voltage or amperage, the motor may not receive the necessary power to maintain consistent operation.

Check the power cord for any damage or loose connections, and make sure it’s plugged into a reliable outlet. If the saw continues to stop, it may indicate a more serious issue with the motor.

A worn or damaged motor can struggle to maintain its rotational speed, resulting in frequent stops. In such cases, seeking professional repairs or considering replacing the motor is advisable to ensure uninterrupted cutting performance.

4. Inadequate or Weak Battery (For Cordless Circular Saw)

If you’re using a cordless circular saw and experiencing frequent stops, it may be due to an inadequate or weak battery. The battery powers cordless circular saws, so if the battery isn’t fully charged or hasn’t enough capacity, it won’t be able to provide the power needed to run the saw.

When the battery is unable to supply enough power, the motor may stall, or the saw may stop altogether. To resolve this issue, make sure you’re using an appropriately sized and charged battery for your circular saw.

If needed, consider upgrading to a higher-capacity battery that can provide more power and longer operating time. This will help ensure uninterrupted performance and prevent the saw from stopping unexpectedly.

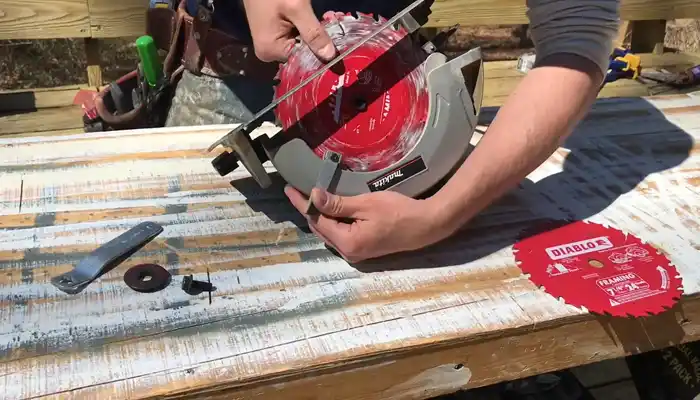

5. Incorrect Blade for the Job

Using an improper blade for your circular saw can result in frequent stops, causing frustration and inefficiency. When the blade isn’t suitable for the material or task, it becomes easily overwhelmed, leading to frequent interruptions and potential damage to both the blade and the saw itself.

To prevent this issue, it’s paramount to always use the correct blade tailored for the specific material you’re cutting. Blades are designed for various materials like wood, metal, or masonry, and employing the wrong blade can compromise cutting performance and put undue strain on the saw.

For instance, when using a circular saw for cutting bamboo or other materials, follow the manufacturer’s blade recommendations. This ensures a smooth and uninterrupted operation of your circular saw, optimizing both performance and longevity.

6. Dull Blades

Dull blades hinder the saw’s ability to cut through materials effectively, causing it to struggle and stop. This occurs because the blade’s dull edges cannot make clean, smooth cuts. Instead, they tear and push through the material, exerting more force and causing the saw to stop.

To prevent this issue, regularly sharpen your blades using a blade sharpener or replace them if they’re beyond sharpening. A well-maintained, sharp blade enhances cutting performance, allowing for smooth and uninterrupted cuts.

7. Resin Accumulation

Resins can build up on the blade over time, impeding its rotation and causing the saw to stop unexpectedly. To resolve this issue, regular cleaning of the blade is necessary to remove the resin buildup.

Use appropriate cleaning agents and follow safety precautions when cleaning the blade. Make sure to disconnect the saw from the power source before cleaning, and wear protective gloves to avoid any potential injuries.

8. Curved Blade Due to Heat

If your circular saw keeps stopping, it may be due to a curved blade caused by excessive heat. Continuous operation, especially on tough materials, can cause the blade to overheat and become curved, leading to potential stops and kickbacks.

To prevent this issue, allowing the blade to cool periodically during prolonged use is important. Simply stopping the saw and giving it a few minutes to cool down can do this.

Investing in high-quality blades designed for heat resistance can help mitigate the problem. These blades are specifically engineered to withstand the heat generated during heavy-duty cutting tasks, reducing the likelihood of blade curvature and frequent stops.

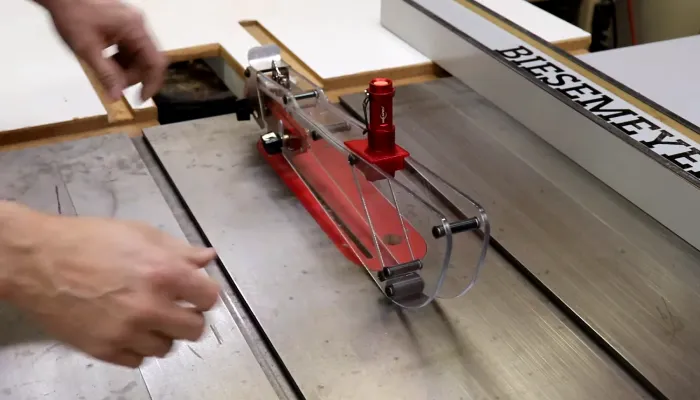

9. Pinching of the Saw Blade

Pinching occurs when the cut material closes in on the blade, causing it to bind and stop. This can happen if the material isn’t adequately supported or if it shifts during the cutting process.

To prevent pinching, ensure the material is firmly secured before starting the cut. Use clamps or a workbench to hold the material steady.

Additionally, consider using a circular saw guide for straight cuts. This tool helps to keep the saw blade aligned and prevents the material from shifting, reducing the risk of pinching.

10. Non-straight Cuts or Shifting Wood

When making non-straight cuts or allowing the wood to shift during cutting, you may experience frequent stops with your circular saw. These stops occur because the blade encounters resistance or the material moves unexpectedly, causing the saw to stop for safety reasons.

To prevent this issue, operating the circular saw correctly is essential. Ensure that your cuts are straight by using a guide or marking the line accurately. This will help maintain a consistent cutting path and prevent the blade from binding.

Make sure the material is securely positioned before starting the cut. Use clamps or other methods to hold the wood in place, reducing the risk of shifting during the cutting process.

11. Incorrect Blade Depth Settings

When the blade depth is set too shallow, it may not cut through the material completely, causing the saw to stall. On the other hand, if the blade depth is set too deep, it can put excessive strain on the motor, leading to overheating and frequent stops.

To avoid these issues, determine the thickness of the material you’re cutting. Then, adjust the blade depth accordingly, ensuring that it protrudes enough to make a clean cut without going too deep.

12. Damaged or Loose Arbor

Inspect the arbor of your circular saw for any damage or looseness to determine if it’s the cause of the frequent stops. The arbor, which is the shaft that holds the blade, plays a crucial role in the proper functioning of the saw.

Over time, the arbor can become damaged due to wear and tear or improper usage. This can lead to the saw stopping unexpectedly during operation. A loose arbor can also cause the blade to wobble, resulting in a loss of cutting precision and potential hazards.

To address this issue, regularly inspect the arbor for any signs of damage or looseness. If any issues are detected, it’s important to replace the arbor following the manufacturer’s guidelines to ensure your circular saw’s safe and efficient operation.

How often should you sharpen your circular saw blade to prevent unexpected stops?

A general guideline is to sharpen the circular saw blade after 20 to 50 hours of use. However, this can vary depending on the type of blade and the materials you’re cutting.

For standard-width, carbide-tipped blades can typically be sharpened 2-3 times before reaching their limit. On the other hand, thin kerf blades may need to be sharpened more frequently, perhaps after just two uses.

You should use a high-quality circular saw blade sharpener to ensure proper sharpening and maintain the blade’s performance.

What should you do if your circular saw overheats and keeps stopping?

If your circular saw overheats and stops, you must take swift action. Start by giving the saw a break and allowing it to cool down. Check for sawdust buildup in the motor and make sure the tool is properly ventilated.

Avoid aggressive cutting and ensure you are using a reliable power source. Additionally, regularly lubricating the saw’s moving parts can help prevent friction and reduce heat. If the issue persists, consult the user manual or seek professional assistance.

Properly addressing overheating will help maintain the tool’s performance and prevent interruptions during operation. Don’t wait until it’s too late, take care of your circular saw to ensure it’s always ready when you need it.

Identify and Fix Your Circular Saw Problems for a Smooth Woodworking Experience

When you face the problem of your circular saw frequently stopping, check out each potential cause meticulously and apply the appropriate solutions I’ve shared. Fixing problems like damaged power cords, sawdust accumulation, or incorrect blade usage will make your woodworking experience smoother and more efficient.

Regular maintenance, such as sharpening your blade using a quality sharpener, will enhance the saw’s longevity. Furthermore, it’s essential to wear a mask during woodworking activities, as sawdust can lead to respiratory issues such as bronchitis.

By prioritizing safety measures and maintaining your circular saw, you can prevent unexpected stops and ensure precise and safe cutting for all your woodworking projects. Keep your tools in top condition, and your circular saw will prove to be a reliable partner for a long time.