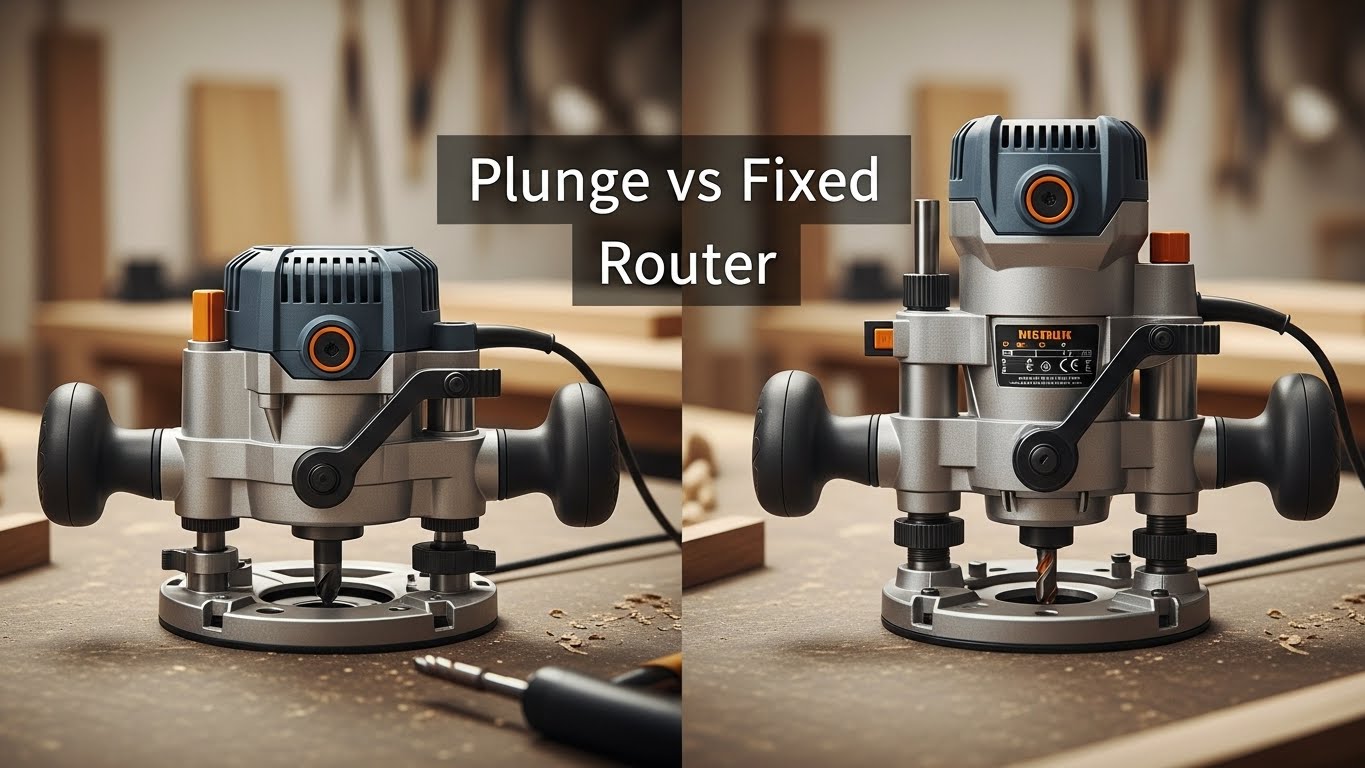

Plunge vs Fixed Router: Core Differences Woodworkers Need

You’ll find fixed-base routers lighter, more compact, and better for precision edgework, thanks to their stable bit position and easy depth control. Plunge routers add weight and complexity with spring-loaded vertical movement, letting you start cuts inside material but requiring more skill and grip strength.

Fixed-base models suit trimming and router tables, while plunge routers handle internal cuts. If you want to optimize your routing setup, exploring these differences further will help you choose wisely.

- Powerful 15-amp variable speed soft start motor provides speeds from 8, 000 to 23, 000 RPM

- Plunging base locks in downward position for functionality as both a plunge and a fixed Router

- Accepts both 1/4 and 1/2-inch Router bits with a plunge depth of up to 2-3/8 inches

- 12 AMP ROUTER MOTOR: Combines ample power with adjustable speed settings, allowing users to glide…

- CONSTANT RESPONSE CIRCUITRY STABILIZES START-UP TORQUETry stabilizes start-up torque

- ADJUSTABLE SPEED DIAL (8000-25,000 RPM)

Key Takeaways

- Fixed-base routers are lighter, more compact, and provide stable, constant bit positioning ideal for edgework and precision cuts.

- Plunge routers offer vertical bit movement with springs and arms, enabling internal cuts and safe starting in the middle of workpieces.

- Fixed-base routers generally provide better one-handed control, micro-adjustment depth tuning, and easier router table mounting.

- Plunge routers have a top-heavy feel due to heavier construction, requiring more grip effort and skill to maintain steady control.

- Plunge routers cost more due to complex mechanisms but excel in versatility for mortises, dados, and internal routing tasks.

Router Comparison at a Glance: Plunge and Fixed Base

| Feature | Fixed-Base Router | Plunge Router |

|---|---|---|

| Bit Movement | Constant, locked bit position | Vertical plunge motion with springs |

| Weight & Balance | Lightweight and balanced | Heavier, top-heavy feel |

| Depth Adjustment | Micro-adjustment dials for fine control | Adjustable plunge stops and depth rods |

| Cut Entry Method | Requires edge access | Safe mid-material entry |

| Precision Consistency | Stable, repeatable cuts | Requires steady control for accuracy |

| Mechanical Complexity | Simple design, fewer moving parts | More components due to plunge mechanism |

| Router Table Use | Easy mounting and reliable depth locking | More challenging due to spring tension |

| Handling Effort | Lower fatigue during extended use | Greater grip strength required |

Design and Weight Differences Between Fixed-Base and Plunge Routers

When you pick up a fixed-base router, you’ll notice its lightweight, compact design, made possible by plastic and lightweight metal bases that snap on and off with ease.

Fixed-base routers feature a lightweight, compact design with easy snap-on plastic and metal bases.

This design reduces weight, allowing one-handed operation and easy storage.

In contrast, plunge routers incorporate stainless steel arms and springs enabling vertical movement, which adds mechanical complexity and weight, typically ranging from 8 to 12 pounds.

Their heavier construction creates a top-heavy feel, impacting portability.

Fixed-base models have fewer moving parts, enhancing simplicity and durability, while plunge routers feature multiple durable components designed for repeated compression and extension.

The compact fixed-base router often fits into the palm router category due to its size and weight advantages, making it more practical for tasks requiring maneuverability and ease of use in tight spaces.

Additionally, plunge routers provide plunge depth capacity that allows for precise vertical adjustments, typically between 2 to 3 inches, which fixed-base models do not offer.

Which Router Is More Accurate and Precise?

Although both router types serve essential woodworking functions, fixed-base routers deliver greater accuracy and precision thanks to their stable, constant bit position and micro-adjustment dials that allow you to control depth with fine increments.

You’ll appreciate how the fixed-base’s reduced moving parts and secure clamping minimize bit movement, ensuring consistent, repeatable cuts ideal for tasks requiring tight tolerances like dovetail joinery.

In contrast, plunge routers inherently introduce variability; their spring-loaded mechanisms can cause the bit to push away from the workpiece, demanding more skill to maintain steady control.

While plunge models offer versatility, their vertical movement complicates precision. Ultimately, if your priority is fine, repeatable depth control and stable bit positioning, a fixed-base router provides superior accuracy, making it the practical choice for precision-driven woodworking.

For optimal performance, it’s essential to ensure proper alignment and tension of your cutting tools to maintain smooth and accurate cuts.

When Should You Use a Plunge Router?

You’ll find plunge routers indispensable for tasks that require starting cuts in the middle of a workpiece or creating intricate internal profiles.

Plunge routers excel when you need to start cuts inside a workpiece or craft detailed internal shapes.

When you need to mill mortises, cut hidden dados, or initiate center cuts safely, a plunge router offers the necessary vertical movement and control.

Its spring-loaded mechanism lets you precisely lower the bit into the material, enabling clean entry without damaging edges.

Use it when your project demands distinct starting and stopping points within the workpiece or when edge access is limited.

Keep in mind that plunge routers weigh more and require firm handling to maintain stability against spring resistance.

However, their versatility in internal routing tasks makes them the ideal choice for complex woodworking operations where fixed-base routers fall short.

For enhanced safety and control during routing, using accessories like featherboards can help maintain consistent pressure and prevent kickback.

Why Fixed-Base Routers Work Best for Edgework and Trimming?

A fixed-base router provides superior control and stability for edgework and trimming tasks, making it the preferred choice for precision cuts along accessible workpiece edges.

You benefit from its lightweight, compact design and micro-adjustment dials that enable fine depth control. This router keeps a constant bit position, reducing the chance of wandering and ensuring cleaner, more accurate cuts when trimming laminates or cabinetry.

The integration of precision cast iron tables in router setups further enhances stability and reduces vibration, contributing to improved accuracy during use.

| Feature | Benefit |

|---|---|

| Lightweight base | Easier one-handed handling |

| Micro-adjustment dials | Precise depth control |

| Constant bit position | Improved cut accuracy |

| Simple design | Reliable, beginner-friendly control |

Comparing Cost and Durability of Fixed-Base and Plunge Routers

When weighing cost against durability, plunge routers generally demand a higher investment due to their complex construction and use of premium materials like stainless steel springs and arms designed for repeated compression and extension.

You’ll find plunge routers incorporate durable components engineered to withstand frequent vertical movement, which justifies their price. In contrast, fixed-base routers have simpler designs with fewer moving parts, relying on lightweight plastic and metal bases that reduce manufacturing costs.

While fixed-base models offer efficient power transfer and ease of maintenance, they may not match the longevity of plunge routers under heavy, repetitive use. If your work involves constant depth adjustments and internal routing, investing in a plunge router guarantees durability.

For basic edgework, a fixed-base router provides reliable performance at a lower cost. Proper locking mechanisms are essential in both router types to ensure stability and safety during operation.

How Ergonomics Affect Comfort and Control With Each Router?

You might’ve noticed that the handle design really impacts how comfortably you can grip and maneuver each router. It’s pretty interesting.

Also, weight distribution plays a big part in this. For instance, plunge routers can feel a bit top-heavy because they’re built heavier, while fixed-base models usually feel more balanced and compact.

These little details are important because they all come together to influence your control and stability when you’re doing precise routing tasks. It’s all about finding that sweet spot for comfort and control, right?

Additionally, maintaining a balanced stance and using proper grip techniques can greatly enhance your comfort and control during tool operation.

Handle Design Impact

Experience with router handles directly influences your control and comfort during operation.

Plunge routers feature ergonomically shaped handles with adjustable resistance and vibration reduction. This allows you to maintain steady pressure while steering complex cuts.

These handles are designed to accommodate the spring-loaded mechanism, giving you precise vertical control but requiring mindful grip to counteract push-back forces.

Fixed-base routers, on the other hand, have simpler, more compact handle designs that promote beginner-friendly control and better heat dissipation.

Their smaller, lighter handles let you maneuver easily for edge work and trimming.

When operating either router, the handle’s shape, size, and material directly affect your grip stability, fatigue level, and cutting accuracy.

Selecting a router with a handle that fits your hand and task guarantees improved performance and reduces strain during extended use.

For enhanced precision and ease of use in woodworking, considering tools with features like integrated cut line systems can significantly improve accuracy and control.

Weight Distribution Effects

Mastering weight distribution is essential to maintaining comfort and control during routing tasks.

With a fixed-base router, you’ll notice its lighter, compact design concentrates weight near the motor and base. This allows easier one-handed use and reduces fatigue.

This balanced center of gravity lets you maintain steady pressure on the workpiece without compensating for top-heaviness.

In contrast, plunge routers incorporate springs and stainless steel arms, adding 8 to 12 pounds and shifting weight upward.

This top-heavy feel demands more from your grip and forearms to stabilize vertical movement, especially during prolonged use.

Understanding these ergonomic differences helps you select the right router for your project, ensuring efficient handling and reduced strain.

Proper weight distribution directly influences your precision and endurance when routing.

Regular maintenance and proper setup of your tools can also improve overall control and reduce fatigue during extended use, as seen in power tools like the Ryobi miter saw.

Control and Stability

Although both fixed-base and plunge routers serve critical functions, their ergonomic designs distinctly influence your control and stability during operation.

Fixed-base routers, being lighter and more compact, enable better one-handed control and constant bit positioning, which enhances stability and precision. Their micro-adjustment dials allow you to fine-tune depth accurately without interrupting your workflow.

In contrast, plunge routers incorporate springs and heavy stainless steel arms, increasing weight and top-heaviness, which demands more effort to maintain steady pressure. While ergonomic handles and vibration reduction improve comfort, the spring resistance can push the tool away from the work surface, challenging your control.

Ultimately, your choice depends on balancing maneuverability with the need for vertical movement. However, fixed-base routers generally offer superior stability for detailed edge work. For woodworking professionals, integrating tools with advanced safety features like the SawStop Contractor Saw can further enhance control and confidence during precise cuts.

Using Fixed-Base and Plunge Routers on Router Tables and Projects

When you’re looking to mount your router on a table, it’s good to know that fixed-base models have some advantages. They usually offer simpler depth locking, and their compact size helps create stable setups. On the other hand, plunge routers can be a bit bulkier and might be trickier to secure, which can be frustrating at times.

Now, if you’re working on projects that need precise and consistent bit depth, fixed-base routers really shine—just think about tasks like edge trimming. They provide that accuracy you need.

But when it comes to internal cuts and mortises, plunge routers bring a lot of versatility to the table. Ensuring your router setup has stable positioning and secure attachment points can significantly improve both safety and precision during use.

Router Table Compatibility

How do fixed-base and plunge routers differ in compatibility with router tables?

Fixed-base routers are generally more compatible due to their lightweight, compact design and stable bit positioning. They easily mount on router tables, allowing you to lock depth precisely with micro-adjustment dials, guaranteeing consistent cuts.

Plunge routers, on the other hand, pose challenges because of their heavier weight and spring-loaded mechanisms, making secure mounting trickier and potentially less stable. Their vertical movement can complicate depth locking when used on tables.

However, some multi-base systems let you interchange fixed and plunge bases on the same motor, offering flexibility.

When working with router tables, fixed-base routers give you practical advantages in ease of setup, stability, and precision. Plunge routers require additional consideration to guarantee safe and accurate operation.

Project Application Differences

Because each router type offers distinct mechanisms and handling characteristics, selecting between fixed-base and plunge routers markedly impacts your project execution and router table use.

You’ll find that fixed-base routers excel in tasks requiring consistent bit depth and stable edge routing, while plunge routers shine in internal cuts and complex mortising.

Consider these practical differences:

- Fixed-base routers offer superior precision on edges and are ideal for trimming and laminate work.

- Plunge routers enable safe starting and stopping cuts inside workpieces, perfect for hidden dados and mortises.

- Fixed-base models mount easily on router tables, providing reliable depth locking for repetitive cuts.

- Plunge routers’ size and spring mechanisms make router table mounting challenging but enhance versatility for freehand tasks.

Choose based on your project needs and workspace setup for peak performance.

Depth Adjustment Control

Although depth adjustment control varies between fixed-base and plunge routers, mastering both is essential for achieving precise cuts in your projects and router table setups.

Fixed-base routers provide micro-adjustment dials and locking clamps, allowing you to set depth accurately and maintain bit stability. Plunge routers rely on spring tension and adjustable stops, which let you plunge to varying depths but require steady control to avoid drift.

| Feature | Fixed-Base Router |

|---|---|

| Adjustment Mechanism | Micro-adjustment dial & clamp |

| Stability | Constant bit position |

| Use | Precise edge and laminate trimming |

| Ease of Locking | Quick, firm locking |

| Skill Required | Beginner-friendly |

Understanding these differences helps you select the right adjustment technique for your project needs.

Frequently Asked Questions

Can I Convert a Fixed-Base Router to a Plunge Router?

You generally can’t convert a fixed-base router into a plunge router directly because their designs differ markedly.

Fixed-base routers lack the necessary internal springs and vertical movement mechanisms found in plunge models.

However, some manufacturers offer multi-base systems where one motor accepts interchangeable fixed and plunge bases.

If your router supports that, you can switch bases, but otherwise, you’d need to purchase a dedicated plunge router for true plunge functionality.

What Safety Gear Is Recommended for Using Each Router Type?

Imagine you’re a knight facing a dragon. Your safety gear is your armor.

Always wear eye protection to shield from flying debris and ear protection against loud noise.

Use a dust mask or respirator to avoid inhaling fine particles.

Gloves protect your hands but keep them tight-fitting to avoid snags.

For plunge routers, add firm grip gloves to counter spring resistance.

Secure your workspace to prevent slips and ensure steady control.

How Do Router Bit Types Differ Between Fixed and Plunge Routers?

You can use most router bit types interchangeably between fixed and plunge routers, but plunge routers handle longer bits better due to their vertical travel and spring mechanism.

Fixed-base routers excel with shorter bits for edge trimming and fine detail work, giving you superior control.

When choosing bits, consider your router’s stability and depth control to make certain precise cuts.

Plunge routers suit internal cuts, while fixed-base routers are best for consistent edge profiling.

Which Router Is Better for Beginners Learning Woodworking?

You’ll find fixed-base routers better for beginners because their simpler design coincides with easier control and precision.

They offer micro-adjustment dials for fine depth settings, making your cuts more accurate without battling spring resistance.

Their lightweight, compact build lets you handle them confidently, while straightforward locking mechanisms reduce setup complexity.

This combination guarantees you focus on mastering your woodworking skills efficiently and safely right from the start.

Are There Multi-Base Routers Combining Fixed and Plunge Features?

Yes, you can get multi-base routers that combine fixed and plunge features.

These models let you swap between a fixed base and a plunge base using the same motor unit.

This versatility saves space and cost while offering you both precise depth control and plunge capability.

You’ll appreciate the ergonomic handles and adjustable resistance on plunge mode plus the micro-adjustments and heat dissipation when using the fixed base.

It’s a practical setup for versatile woodworking.

Fixed Base or Plunge Router: Decide with Confidence

Choosing between a plunge and fixed-base router is like picking the right tool from a craftsman’s belt. Each fits a specific purpose.

You’ll want a plunge router when depth adjustments mid-cut are essential, while a fixed-base router excels at edgework and trimming with precision.

Consider your project’s demands, ergonomics, and budget to make the smartest choice.

In the end, mastering both gives you the versatility to tackle any routing challenge with confidence and control.

- Our most powerful 20V MAX* cordless router** – take on tough applications without the hassle of a…

- Help maximize productivity – complete up to 256 linear feet routing 5/8 in. roundovers in pine on a…

- Integrated dust collection with AIRLOCK compatibility – collects up to 97% of dust cutting grooves…

- 10 AMP FIXED BASE ROUTER TOOL—Powerful 10 Amp, 2.0 HP motor provides smooth and accurate routing…

- SPEED CONTROL—Lets you adjust speed based on the material.

- SOFT START—Provides a safe and controlled start to routing.

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API