Bowl Gouge vs Spindle Gouge: Key Differences Explained

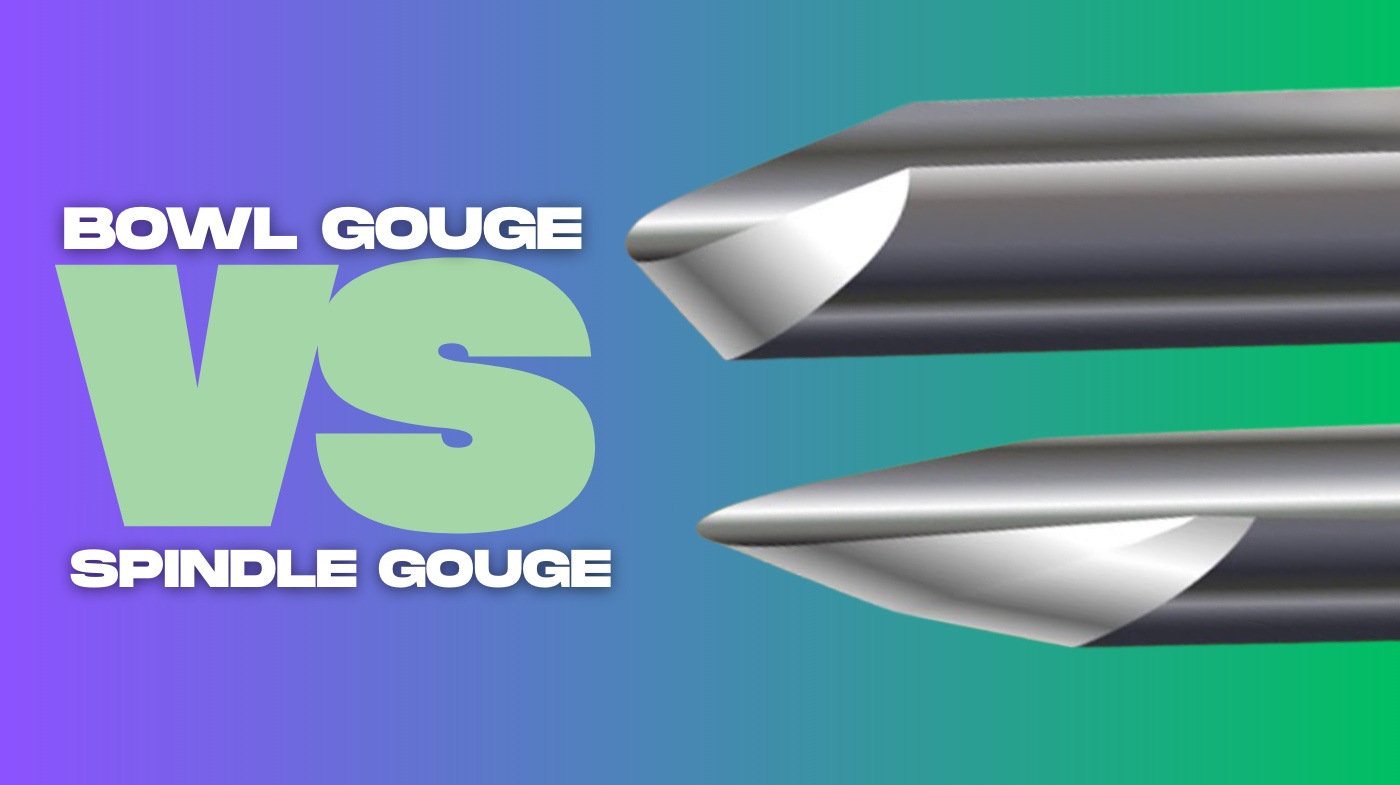

When choosing between a bowl gouge and spindle gouge, know that a bowl gouge’s deep, U-shaped flute excels at fast material removal and shaping large, curved vessels with heavy cuts.

In contrast, a spindle gouge offers a shallower flute and finer bevel angles for delicate, precise spindle detailing like beads and coves.

Each tool’s design affects handling, cutting dynamics, and durability. Understanding these differences will help you match the right gouge to your woodturning needs efficiently.

- SHARPENED CHISEL HEADS – Accurately pre-sharpened by machine for all turning tools

- BLADE – 9-Inches High Speed Steel blades outlast high carbon steel and will give you years of use

- HANDLE – 15.3-Inches teak wood handle is harder and comfortable for using

- High speed steel resists “blued” softening from overheating

- Sharpened edge lasts 6 times longer than carbon steel

- Fingernail medium grind

Key Takeaways

- Bowl gouges have deep, U-shaped flutes ideal for aggressive hollowing and shaping large, curved facegrain vessels.

- Spindle gouges feature shallower, broader flutes designed for detailed, controlled cuts on spindles and small-diameter projects.

- Bowl gouges prioritize durability and impact resistance with heavier steel and robust tangs for heavy material removal.

- Spindle gouges offer lighter handles and slimmer tangs for agility and precision in fine detailing and spindle work.

- Sharpening angles differ: bowl gouges use 40–55° bevels for smooth curves, while spindle gouges maintain 40–45° for delicate cuts.

At a Glance: Understanding Gouge Differences

| Feature | Bowl Gouge | Spindle Gouge |

|---|---|---|

| Flute Design | Deep, U-shaped flute for heavy cuts and smooth curves | Shallow, wide flute for delicate shaping |

| Primary Use | Hollowing bowls, shaping large curved vessels | Spindle work, beads, coves, and fine details |

| Cutting Strength | Handles aggressive, high-pressure cuts with ease | Optimized for light, precise slicing cuts |

| Bevel Angle | 40–55° with option for micro bevels (60–65°) | 40–45° with longer bevel for precision |

| Handle Length | Longer (10–12″) for leverage and hip support | Shorter (7–10″) for agility and control |

| Material & Durability | Made from heavy-duty HSS, strong tang, resists stress | Slimmer tang, lighter build, less robust |

| Best Grain Orientation | Facegrain turning (bowls, platters, curved stock) | Long-grain turning (legs, spindles, finials) |

| Maintenance Needs | Requires frequent sharpening due to tough cuts | Less frequent sharpening, but delicate tip care needed |

Flute Design and Shape Differences

While both bowl and spindle gouges serve distinct turning purposes, their flute designs differ markedly to optimize performance. Bowl gouges feature a deep, U-shaped flute that allows aggressive material removal and smooth cutting on curved surfaces. This deep flute creates a robust, rounded cutting edge, which is essential for controlling tool behavior during bowl hollowing and avoiding catches.

In contrast, spindle gouges have a shallow, broader flute dividing the shaft nearly in half, producing a thinner, finer cutting edge. This design favors precision over robustness, enabling delicate detail work. The flute’s shape also influences tool stiffness: bowl gouges sacrifice some metal under the flute for strength in heavy cuts, while spindle gouges retain more material for stiffness but handle lighter cuts.

Flute orientation further directs each gouge’s cutting techniques and control. The spindle gouge’s tip is typically ground to a fingernail shape, which is ideal for making fine, controlled cuts on spindle work. Additionally, selecting proper tool design considerations can significantly affect control and user comfort during turning.

Primary Uses and Applications of Each Gouge

When you choose between a bowl gouge and a spindle gouge, understanding their distinct functions is vital.

The bowl gouge excels at heavy material removal and hollowing, making it ideal for shaping large vessels. Its shank size and flute profile provide the leverage and cutting capacity needed for these tasks. This tool is often favored for projects requiring cutting capacity similar to the demands met by double bevel miter saws.

In contrast, the spindle gouge focuses on detailed, controlled cuts specifically for spindle work. Matching each tool’s strengths to your project guarantees efficient and precise woodturning results.

Bowl Gouge Functions

Because the bowl gouge is specifically engineered for hollowing and shaping large, curved wooden objects, it excels at creating smooth, rounded interiors and exteriors of bowls and platters. You’ll find it indispensable for efficiently hollowing deep cavities and shaping outer surfaces with precision.

While primarily designed for these tasks, the bowl gouge also enables you to achieve a fine, polished finish on curved wood. Its robust, fluted U-shaped edge allows for supported cuts that follow the wood grain, minimizing catches.

The bowl gouge is typically made from high-speed steel (HSS), providing durability and maintaining sharpness during prolonged use. Proper maintenance, including regular sharpening and careful handling, ensures the gouge’s cutting precision and longevity. Although it’s not primarily a detail tool, with careful control, you can execute subtle detailing.

Spindle Gouge Roles

Shaping spindles demands a different approach than hollowing bowls, and the spindle gouge is tailored specifically for this task. You’ll use it primarily for long-grain turning, shaping chair legs, stair balusters, and similar pieces. These applications benefit greatly from woodworking techniques that enhance precision and finish.

Its design—with a shallower flute and steeper grind—lets you craft smooth beads, coves, and ogee curves efficiently. This minimizes catches compared to a skew chisel. The tool’s tip performs slicing cuts, enabling precise control and near-finish surfaces, especially when detailing smaller diameters.

The spindle gouge typically features a fingernail profile grind, providing excellent maneuverability for intricate shapes.

Beyond spindles, you can employ it for shallow hollowing and light drilling on delicate projects like finials. Different sizes serve complementary roles: larger gouges shape broad curves, while smaller ones refine intricate details. Keep in mind its grind and flute design make it unsuitable for bowl turning.

Application Suitability

Although both bowl and spindle gouges serve essential roles in woodturning, their application suitability hinges on the specific demands of your project.

You’ll rely on bowl gouges primarily to shape and hollow large, curved facegrain objects like bowls and platters, benefiting from their stout design and ability to handle heavy wood removal with downward pressure. Their deep, oval flutes and micro-bevel grinds enable controlled, smooth cuts, even in challenging woods. The rod and flute design provides strength and efficient chip removal, which is key for faceplate work.

Conversely, spindle gouges excel at detailed spindle work—turning slender forms and hollowing end-grain projects such as boxes and goblets—where finesse outweighs brute strength.

Choosing between them depends on your wood’s grain orientation, piece size, and required cut type: bowl gouges for robust, aggressive shaping on faceplate work; spindle gouges for precise, intricate detail on spindles and smaller components.

Construction and Durability Comparison

You’ll find that bowl gouges use heavier, high-carbon steel and robust tangs to withstand the stresses of deep hollowing. This is similar to how chainsaws designed for heavy-duty tasks incorporate durable materials to enhance resilience.

In contrast, spindle gouges favor lighter construction and slimmer handles optimized for precision control. These differences in material strength and handle design directly impact each tool’s durability and performance under varying cutting conditions.

The shape and depth of the flute also play a crucial role, with spindle gouges having a shallower flute compared to bowl gouges, influencing their specific applications.

Tool Material Strength

When comparing bowl and spindle gouges, their tool material strength substantially impacts performance and durability under different cutting conditions. Bowl gouges typically use high-speed steel (HSS), often cryogenically treated M2, which enhances edge retention and resistance to wear during heavy end-grain cutting.

Their deep U- or V-shaped flutes maintain steel thickness near the tip, bolstering structural strength and durability. In contrast, spindle gouges employ lighter-grade HSS with shallower, wider flutes that thin the steel at the tip, prioritizing maneuverability but reducing robustness.

Bowl gouges’ robust, swept-back tips withstand aggressive cuts and resist chipping. Meanwhile, spindle gouges’ finer tips suit precise detail work but are prone to damage under heavy loads.

Additionally, the bowl gouge’s larger cutting edge allows it to efficiently remove large amounts of wood, particularly in roughing and hollowing stages, whereas the spindle gouge is designed primarily for fine detail work. The choice of tool also depends on ergonomic factors such as balanced weight distribution, which can affect user comfort during extended use.

Handle and Tang Design

The strength of a gouge’s steel is only part of what determines its effectiveness. Handle and tang design substantially influence control and durability during use.

Bowl gouge handles are longer (10–12 inches) and sturdier, offering leverage and a robust grip for heavy cuts and hollowing. Their tangs embed deeply and feature reinforced construction to resist twisting and lateral forces.

In contrast, spindle gouge handles are shorter (7–10 inches), designed for agile, precise movements. They’ve slimmer, lighter tangs that reduce handle weight without compromising stability.

Both types utilize dense hardwoods and protective finishes. However, bowl gouges prioritize impact resistance, while spindle gouges focus on smoothness for quick hand adjustments.

This tailored design ensures each gouge meets the specific mechanical demands of its intended turning tasks effectively and durably. For woodworking tools, motor power and voltage, such as the motor options from 1.75 HP to 7.5 HP, can significantly affect performance and efficiency.

Cutting Edge Geometry and Sharpening Techniques

Although bowl and spindle gouges serve distinct turning purposes, understanding their cutting edge geometry and sharpening nuances is essential for mastering control and achieving clean, efficient cuts.

Proper maintenance practices such as regular honing and cleaning contribute significantly to the longevity and performance of these tools, preventing premature wear from frequent use.

Mastering gouge geometry and sharpening nuances is key to precise control and clean, efficient woodturning cuts.

Bowl gouges feature a continuous curved cutting edge with a bevel angle between 40–55°, often finished with a micro bevel for fine detail. The micro bevels (60-65°) enable reaching tight curves and the bottom of deep bowls without heel rubbing.

Spindle gouges have a shallower flute and longer bevel optimized for precise slicing, with bevel angles around 40–45°. Selecting the appropriate bevel angle and maintaining proper cutting speed and feed rate help prevent blade dullness and extend tool life.

Sharpening demands consistent bevel angles and smooth progressions to maintain cutting efficiency and edge durability.

Bowl gouges rely on bevel riding for smooth cuts; spindle gouges require precise tilt and flute orientation. Micro bevels enhance edge retention on bowls; spindle gouges balance sharpness and durability.

Use jigs or steady hands to maintain consistent bevels. Regular honing reduces friction and guarantees clean, controlled cuts.

Handling and Safety Considerations

Mastering cutting edge geometry and sharpening sets the stage for safe and effective tool handling. You must recognize that bowl gouges, with their robust design and optimized bevel angles, safely endure heavy end-grain cuts. Bowl gouges typically feature a parabolic flute profile, which provides better control and smoother cuts during bowl shaping.

In contrast, spindle gouges, especially roughing types, have weaker tangs unsuitable for bowl work and risk breakage if misapplied. Always anchor your tool firmly on the rest and maintain bevel rubbing to stabilize the cut and minimize catches.

Use smooth, controlled motions from bowl edge toward center, and ensure your gouge is razor-sharp to prevent sudden tool grabs. Adjust tool rest height and lathe speed to maintain proper bevel contact and manageable forces.

Performance in Material Removal and Precision

When you prioritize rapid material removal, bowl gouges excel with their deep, U-shaped flute that delivers smooth, efficient cuts ideal for hollowing bowls and shaping large curves. Their robust design reduces vibration and effort during heavy cuts, making them less suitable for fine detail. The side wings on the bowl gouge provide structural strength that supports the flute and prevents it from folding under pressure.

In contrast, spindle gouges offer precision and control with a shallow, wide flute and a rounded, fingernail-shaped tip. This design allows you to create intricate beads, coves, and delicate spindle features without removing excess material.

Key points to contemplate:

- Bowl gouges remove large volumes quickly, ideal for broad shaping.

- Spindle gouges provide finesse for detailed, precise cuts.

- Bowl gouges’ bulkier tips reduce maneuverability in tight spaces.

- Spindle gouges excel at controlled light cuts, preserving intricate details.

Tool Selection for Woodturning Projects

Since each woodturning project demands specific techniques and outcomes, selecting the right gouge is essential for efficiency and safety.

Use bowl gouges for roughing out and shaping large, curved stock like bowls. Their deep flute and long handles let you apply controlled, powerful cuts with better chip clearance. The longer handle of the bowl gouge also allows it to be rested on the hip during use, providing greater control and comfort. Maintaining proper tool control is crucial to prevent accidents and ensure smooth cuts.

For detailed spindle work—tenons, beads, coves—opt for spindle gouges with shallower flutes and steeper grind angles. This allows delicate manipulation without hip support.

Avoid using spindle gouges for heavy bowl cuts to prevent catches and unsafe tool behavior. A well-rounded toolkit includes multiple bowl gouges for rough shaping and at least one spindle gouge for fine detail.

Impact of Flute Design on Cutting Dynamics

Although both bowl and spindle gouges share the fundamental purpose of shaping wood, their distinct flute designs critically influence cutting dynamics.

The deep, U-shaped flute of a bowl gouge enables rapid, controlled removal of large wood volumes with smooth slicing actions. This design enhances tool rigidity and reduces vibration, making it ideal for robust cutting tasks. Additionally, bowl gouges often feature a swept-back bevel that facilitates both roughing out and finishing bowl interiors and exteriors.

Proper dust management during use is essential to maintain cutting performance and air quality, as seen in tools with dust collection systems.

In contrast, spindle gouges have shallower, wider flutes optimized for fine, intricate cuts. This requires careful handling to avoid catches due to the reduced metal support around the cutting edge.

- Bowl gouge flutes provide a full cutting edge with robust engagement.

- Shallow spindle gouge flutes enable delicate, precise detailing.

- Detail spindle gouges balance shallow flutes with increased stiffness to minimize chatter.

- Flute shape affects bevel consistency, influencing cutting precision and user control.

Maintenance and Edge Retention Strategies

Mastering maintenance and edge retention strategies is essential to maximize the performance and lifespan of both bowl and spindle gouges.

For bowl gouges, frequent sharpening is necessary due to aggressive material removal. Maintain the swept-back grind using sharpening jigs or angled grinding wheels.

Regular honing preserves sharpness and smooth cutting, while light oil or wax prevents rust. Inspect flutes and bevels for nicks to ensure safety.

Spindle gouges require less frequent sharpening but demand careful grinding to preserve the delicate fingernail-shaped tip. The depth of the flute affects how the gouge performs and should be considered during maintenance.

Frequent honing and careful storage prevent damage and maintain precision. Use stropping for both tools to extend edge life.

Frequently Asked Questions

Can Bowl Gouges Be Used Effectively on Spindle Projects?

Yes, you can use bowl gouges on spindle projects, especially for roughing larger stock where their strength and material removal excel.

However, for detailed shaping and fine cuts, you’ll find spindle gouges offer better control and precision.

To use bowl gouges effectively on spindles, maintain sharp edges, use proper tool rest positioning, and adapt your technique to avoid catches.

It demands skill but can be done safely and efficiently with practice.

What Is the Typical Cost Difference Between Bowl and Spindle Gouges?

Back in the days of knights and castles, you’d find bowl gouges generally cost a bit less than spindle gouges, especially at entry-level.

You’ll pay around $80-$120 for quality bowl gouges, while spindle gouges hover near $100-$120, thanks to specialized steels like M42.

The price gap narrows with premium models using advanced steels and features.

Are There Specific Wood Types Better Suited for Each Gouge?

Yes, you’ll want to match your gouge to the wood type. Use bowl gouges for dense hardwoods like walnut, maple, cherry, and oak because they handle end grain and complex grains well.

For softer woods with straight grain, like pine, cedar, poplar, or basswood, spindle gouges deliver finer detail and smoother cuts.

Avoid spindle gouges on hard, interlocked grains to prevent chipping and catches during turning.

How Do Handle Lengths Affect Control for Each Gouge Type?

You’ll find shorter handles give you finer control and quicker response, perfect for detailed spindle work where precision matters.

Longer handles provide better leverage and balance, helping you manage heavier cuts smoothly.

Using a handle that’s too long on detailed cuts can reduce tactile feedback, while a handle that’s too short for power cuts limits your control.

Match handle length to the task to optimize comfort, control, and effectiveness.

Can Beginners Start With Spindle Gouges Before Using Bowl Gouges?

Think of starting with spindle gouges as learning to dance before performing acrobatics. Yes, you can absolutely begin with spindle gouges—they’re safer and more forgiving, letting you develop precise control and basic cutting skills.

This foundation builds your confidence and dexterity, making the shift to bowl gouges smoother. By mastering the spindle gouge first, you reduce the risk of catches and improve your technique for more aggressive, complex bowl work later.

Make the Right Choice for Your Woodturning Journey

You’ll find the bowl gouge excels in sweeping curves and heavy material removal, while the spindle gouge thrives on detailed shaping and fine cuts.

Though their flute designs and edge geometries differ, both demand precise sharpening and careful handling. Choosing between them means balancing power with finesse, durability with control.

By understanding these contrasts, you’ll optimize your tool selection, maximize performance, and maintain sharpness for every woodturning challenge you face.

- Bar Diameter: 5/8″ | Flute Width: 1/2″

- Flute Length: 6″ | Handle Length: 15″ | Overall Length: 24″

- Made from High Speed Steel with solid beech handle

- Includes: 1/2″, 1″4, and 3/8″ Spindle Gouges

- HurricaneTools_HSG14, HurricaneTools_HSG38, HurricaneTools_HSG12

- Used to create details such as beads and coves on long grain pieces

Last update on 2026-01-12 / Affiliate links / Images from Amazon Product Advertising API