Track Saw vs Circular Saw: 7 Key Differences

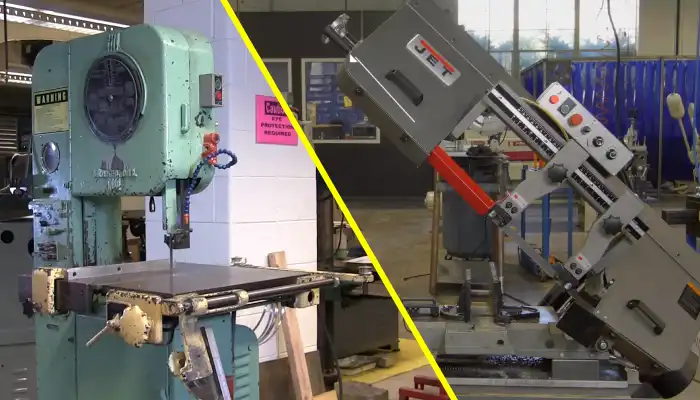

Track saw and circular saw are two essential cutting tools in the woodworking industry. Both saws have unique features that make them ideal for various tasks. But they have significant differences in many aspects.

As a woodworking enthusiast, I conducted research to compare and contrast the two saws. A notable difference I found between track and circular saws is the visibility of their blades.

The track saw features an enclosed blade, providing a safer cutting experience for the user. In contrast, circular saws have more visible blades, requiring users to exercise caution.

I will discuss all the differences between the two saws to help you determine the best fit for your woodworking needs.

- Powerful 10-Amp Motor

- Versatile 45° Bevel Capability

- Plunge Ready for Precision Cuts

- Compatible with WEN Track Accessories

- Dust Collection for Clean Operation

- Powerful 5150 RPM Motor

- Durable Magnesium Shoe

- Optimized Rubber Comfort Grip

- 0-50 Degree Bevel Capacity

- Brushless Technology for Efficiency

7 Differences Between Track Saw and Circular Saw

Exploring the distinctions between track saws and circular saws reveals crucial nuances in functionality, precision, and versatility. Here are the key differences that illuminate the unique characteristics of these two essential woodworking tools.

- Blade visibility

- Material compatibility

- Setup speed

- Precision and control

- Dust collection

- Path control

- Cost considerations

1. Blade Visibility

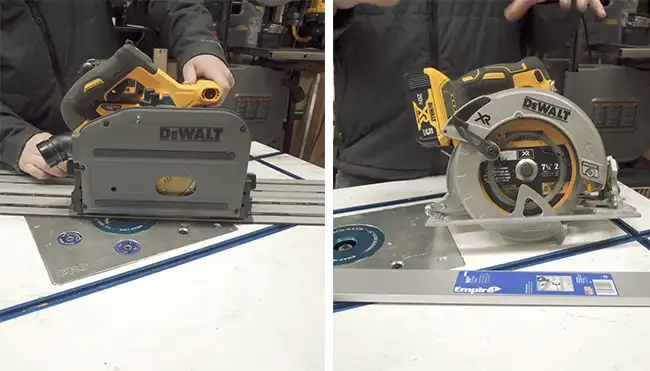

When I compare the blade visibility between a track saw (also known as plunge saw) and a circular saw, I notice a distinct difference in safety.

With a track saw, the blade is often enclosed, ensuring that the user can focus on the cut without worrying about direct exposure to the blade. This design feature greatly enhances safety during cutting operations, especially for those who prioritize safety in their work.

Conversely, circular saw blades are more visible, requiring users to exercise caution. While safety features are present, the direct visibility of the blade might be a consideration.

2. Material Compatibility

With a track saw, you can confidently cut through various materials due to its compatibility with different types of blades. Whether you’re working with plywood, sheet goods, or other materials, the track saw can accommodate the appropriate blade for the task at hand.

This means you can achieve clean and precise cuts without worrying about damaging the material or compromising the quality of your work.

Meanwhile, a circular saw with a guide can also cut different materials, including wood, metal, and tile. The precision may vary, and you may need to switch out blades for specific materials.

3. Setup Speed

According to my findings, setting up a track saw is quicker than a circular one with a guide. With a track saw, all you need to do is align the track with your cut line, secure it in place, and you’re ready to go. This process is fast and efficient, making it ideal for tasks requiring frequent adjustments and high precision.

Conversely, setting up a circular saw can take more time. While some users appreciate the simplicity and familiarity of their homemade guides, the trade-off is a longer setup time.

4. Precision and Control

A track saw, with its integrated track, provides superior precision for fine cuts on sheet goods. The track acts as a guide, ensuring accurate and clean cuts without the need for additional guides. This level of control allows for more intricate and delicate work, such as cutting veneered plywood or melamine.

Conversely, with a guide, a circular saw can provide accurate cuts, but it may require more attention to achieve the same level of precision.

Users emphasize the importance of having a perpendicular piece of wood to ensure square cuts. While precision is achievable, it may not be as consistent or effortless as with a track saw.

5. Dust Collection

In my research, I also discovered that track saws are known for their superior dust collection capabilities due to their enclosed design and integrated dust ports. These features ensure that a larger percentage of the dust generated during cutting is captured and directed into a dust collection system or vacuum.

On the other hand, circular saws with guide systems may not offer the same level of dust collection features. The homemade guide used with circular saws may not effectively contain the dust, leading to a messier working environment.

Therefore, if dust collection is a priority for you, opting for a track saw with its specialized dust collection features would be the better choice.

6. Path Control

If you’re looking for precise and controlled cutting, a track saw offers superior path control compared to a circular saw. With its integrated guide rail system, a track saw ensures straight and accurate cuts every time.

The guide rail acts as a dedicated path for the saw, eliminating the need for manual adjustments or the use of homemade guides. This results in cleaner and smoother cuts with minimal tear-out.

On the other hand, a circular saw with a guide relies on the quality and design of the homemade guide, which may not always provide the same level of control as a track saw.

While users may achieve satisfactory results with a circular saw and guide, the path control isn’t as precise and consistent as with a track saw.

7. Cost Considerations

For those comparing a track saw and a circular saw, cost plays a significant role in the decision-making process. Track saws are generally considered more expensive than a circular saw setup.

However, many users argue that the tool’s efficiency and precision justify the initial higher cost. With a track saw, you get a dedicated system that ensures straight cuts with minimal effort.

In contrast, a circular saw with a homemade guide can be a more cost-effective solution. If you already own a circular saw and find DIY solutions sufficient for your needs, investing in a track saw may not be necessary.

Ultimately, the decision depends on your budget and the level of precision and convenience you require.

Chart Comparing Track Saws and Circular Saws

| Aspects | Track Saw | Circular Saw with Guide |

| Blade Visibility | Enclosed blade for safety. | Visible blades, exercise caution. |

| Material Compatibility | Excel in cutting various materials. | Versatile but may need different blades. |

| Setup Speed | Generally faster setup. | Longer setup time, DIY simplicity. |

| Precision and Control | Superior precision with integrated track. | Accurate with a DIY guide, needs attention. |

| Dust Collection | Benefits from improved dust collection. | Homemade guides may be less efficient. |

| Path Control | Excellent path control for straight cuts. | Path control depends on guide quality. |

| Cost Considerations | Generally more expensive. | Cost-effective with existing circular saws. |

How do track saws stay in place during cuts?

To ensure stability and control during cuts, track saws use a pair of anti-slip strips on the underside of the track. These strips are made from a high-friction material that grips the surface of the workpiece, preventing any movement or slipping as you guide the saw along the track.

The anti-slip strips are strategically positioned to distribute the force evenly across the track, ensuring a secure connection between the saw and the workpiece. This design feature is especially useful when making long, straight cuts or when working with large and heavy materials.

As a result of the anti-slip strips, you will be able to focus on the precision of your cuts without worrying about the track shifting.

Can you use a circular saw blade on a track saw?

You can attach a circular saw blade to a track saw if it has the appropriate size and specifications. While track saws are designed to work optimally with their own blades, using a circular saw blade can provide flexibility if you already have a collection of such blades.

To ensure compatibility, the circular saw blade should match the size and specifications the track saw manufacturer recommends. It’s important to note that while this makeshift solution may work for some tasks, it may not deliver the same level of precision and performance as a dedicated track saw blade.

The decision to use a circular saw blade on a track saw depends on your specific needs and the level of precision required for your woodworking projects. Additionally, when considering the use of a circular saw blade on a track saw, it’s essential to maintain the sharpness of the blade for optimal performance.

Regularly check for blade wear, and if necessary, use a high-quality circular saw blade sharpener to maintain sharp cutting edges. A sharp blade not only enhances the efficiency of the cutting process but also contributes to cleaner and more accurate cuts.

Can a circular saw be utilized for making miter cuts?

Using a circular saw, you can achieve precise miter cuts by employing a guide and adjusting the blade angle as needed. The guide serves as a reliable reference, ensuring that your cuts align with the desired angle.

To make miter cuts, start by securing the guide to the workpiece, allowing the circular saw to glide smoothly along its edge.

Next, adjust the blade angle to match the desired miter angle. Most circular saws have a bevel adjustment feature that allows you to tilt the blade to the desired angle.

Combining the guide and adjustable blade angle allows you to create miter cuts in your woodworking projects accurately.

It’s important to note that using a miter saw or a track saw may provide even greater precision and ease for making miter cuts, but a circular saw can still be a viable option if used correctly.

Compare the Track Saw and Circular Saw and Make the Right Choice

When you decide between a track saw and a circular saw, weigh the differences that I’ve shared to align with your woodworking priorities. Consider the enhanced safety of an enclosed blade in a track saw versus the visible blade of a circular saw.

Assess the speed of setup, precision, and dust collection features to match the demands of your projects. Recognize that while track saws come with a higher initial cost, they offer efficiency and precision.

On the other hand, a circular saw with a guide provides a cost-effective alternative. Your choice ultimately hinges on budget, preferences, and the level of precision you seek.

- Precise Plunge Cuts: Clean, splinter-free cuts up to 2-1/3 inches.

- Versatile Track System: (2) 50-inch tracks for straight cuts over 8 ft.

- Wide Bevel Capability: Cuts bevels up to 45 degrees.

- Powerful 10A Motor: Easily cuts boards and sheet goods.

- Adaptable Compatibility: Fits Evolution, Makita, and Festool tracks.

- Powerful 15-Amp Motor, 5,300 RPM

- Single-Beam Laser for Accurate Cuts

- 51° Bevel with Positive Stops

- Integrated Dust Blower for Visibility

- Spindle Lock for Easy Blade Changes

Last update on 2026-02-22 / Affiliate links / Images from Amazon Product Advertising API