Do I Need a Table Saw: Behind the Reasons

The question of whether or not a table saw is essential in a woodworking shop is a common dilemma for both novice and experienced woodworkers. No matter whether miter saws, circular saws, and routers are available, I think you need to understand what a table saw can do.

After extensive research, I realized the table saw’s versatility and accuracy were unmatched. A table saw is considered a cornerstone tool, a workhorse that offers an array of advantages and capabilities that are hard to match.

It brings precision, versatility, and efficiency to woodworking projects, making it an invaluable asset for professionals and hobbyists.

Here, I’ll explain the reasons why a table saw is a must-have for any serious woodworking job. And why it should be part of every woodworker’s arsenal.

Why Do You Need a Table Saw: 10 Reasons

Table saws are a key tool in woodworking, and I believe they are mainly essential for 10 reasons:

- Precision and accuracy

- Speed and efficiency

- Versatile cuts

- Consistency in production

- Handling large workpieces

- Perfect for diverse materials

- Precision joinery

- Versatile blade options

- Resawing

- Safety features and accessories

No 01: Precision and Accuracy

Because of its ability to provide precise and accurate cuts, a table saw is an indispensable tool for any woodworking job. The rip fence and miter gauge systems on a table saw ensure consistent straight cuts, making it ideal for ripping boards or creating square and uniform pieces.

Adjusting the blade height and angle with precision is crucial for creating bevels and various wooden cuts. Additionally, the stability and power of a table saw contribute to its accuracy.

As far as I know, the sturdy tabletop and strong motor allow for smooth and controlled cuts, ensuring accuracy and reducing the risk of errors.

No 02: Speed and Efficiency

According to my findings, to maximize the speed and efficiency of your woodworking projects, a table saw is an essential tool. With the table saw’s fixed blade and sliding fence, it is easy to cut long boards lengthwise on the table saw.

When working with substantial quantities of wood, such as solid lumber or sheet goods, the table saw’s power and precision allow for rapid and accurate cuts. This is especially crucial for professional woodworkers who’ve tight deadlines or need to process materials quickly.

With a table saw you can confidently tackle projects that would otherwise be time-consuming and labor-intensive. Its speed and efficiency make it a valuable asset in any woodworking job, saving you both time and effort.

No 03: Versatile Cuts

With the ability to make cross-cuts, dados, rabbets, and tenons, among other cuts, all on a single machine, you can save both space and money by minimizing the need for multiple specialized tools.

Whether building cabinets, crafting furniture, or constructing intricate woodwork, the table saw provides the accuracy and efficiency you need to achieve professional results. Its versatility and adaptability make the table saw an essential tool for any serious woodworker.

No 04: Consistency in Production

I believe that, for a woodworker, having a table saw is crucial for maintaining consistency in production and achieving professional results.

Table saws that make consistent and precise cuts ensure that each piece is the same size and shape, eliminating variations that can compromise the quality. With a table saw you can easily adjust the settings to achieve the desired dimensions, allowing you to create uniform pieces with ease.

This level of consistency not only enhances the aesthetic appeal of your work but also ensures that the pieces fit together seamlessly. It results in a finished product that’s both visually pleasing and structurally sound.

No 05: Handling Large Workpieces

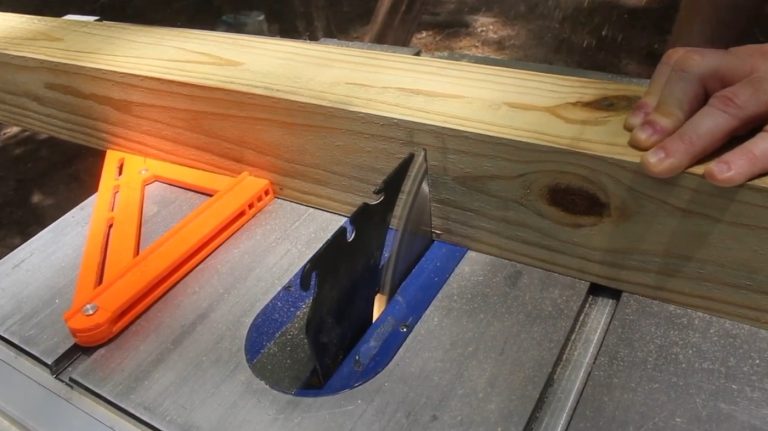

On my side, for handling large workpieces in woodworking projects, a table saw is essential due to its ability to provide stability, control, and ease of cutting.

When working with oversized materials like large slabs, plywood sheets, or hardwood boards, the large table and extensive support surface of a table saw make it easier to manage and cut these unwieldy pieces.

The stability offered by the table saw ensures that the workpiece remains firmly in place, reducing the risk of mishaps or errors during cutting. Additionally, the control provided by the table saw allows for precise and accurate cuts, even with large and cumbersome materials.

No 06: Perfect for Diverse Materials

Table saws aren’t limited to wood; they can also handle p lastics, laminates, and even metals when equipped with the appropriate blades. This makes them invaluable in settings where you must work with different materials for specific projects.

As I know, the table saw’s powerful motor and adjustable blade height allows efficient cutting of diverse materials, ensuring clean and accurate results. Whether working with hardwood, plywood, or non-ferrous metals, a table saw provides the necessary stability and control to make clean and precise cuts.

No 07: Precision Joinery

Because a table saw enables you to create precise and strong joinery, it’s an essential tool for any woodworking job.

The accuracy and control provided by a table saw allow the ability to achieve tight-fitting joints crucial for the structural integrity and the visual appeal of my projects. Whether you’re working on dovetails, box joints, or mortise-and-tenon connections, I am sure the table saw ensures that each cut is made precisely.

No 08: Versatile Blade Options

With its ability to accommodate a wide range of circular blade options, a table saw becomes an indispensable tool for a woodworking job. The versatility in blade options allows for precise customization, ensuring you have the right tool for every task.

Cross-cutting blades with numerous teeth are ideal for making smooth, clean cuts across the grain while ripping blades with fewer teeth excel at cutting along the grain. By swapping out blades based on your project’s requirements, you can achieve cleaner cuts and improved results.

Additionally, table saws offer options for specialty tools, such as dado blades for making grooves and rabbeting blades for creating precise joinery. For any woodworker, the ability to choose different blades for a table saw is essential.

No 09: Resawing

Another reason I prefer a table saw for your woodworking project because it’s excellent at resawing thick boards into thinner ones. Resawing is a technique that involves cutting a board along its thickness, resulting in two or more thinner pieces.

This process is crucial for obtaining thinner lumber or creating book-matched panels, where two identical pieces are joined together to form a symmetrical pattern.

A table saw with a high-quality fence is ideal for this task because it provides stability and precision during the cutting process. The fence ensures the board remains parallel to the blade, resulting in accurate and consistent cuts.

No 10: Safety Features and Accessories

While table saws provide numerous safety features and accessories, one can’t overlook their importance for a woodworking job. These safety features are designed to minimize the risk of accidents and ensure the user’s well-being.

One such feature is the riving knife, which prevents kickback by keeping the wood from pinching the blade. Blade guards are another important accessory that protects the user’s fingers from accidental contact with the spinning blade.

Additionally, accessories like feather boards help to maintain consistent pressure on the workpiece, reducing the likelihood of kickback. Push sticks are also commonly used to keep hands safe from the blade while guiding the wood through the cut.

What Are the Main Types of Table Saws?

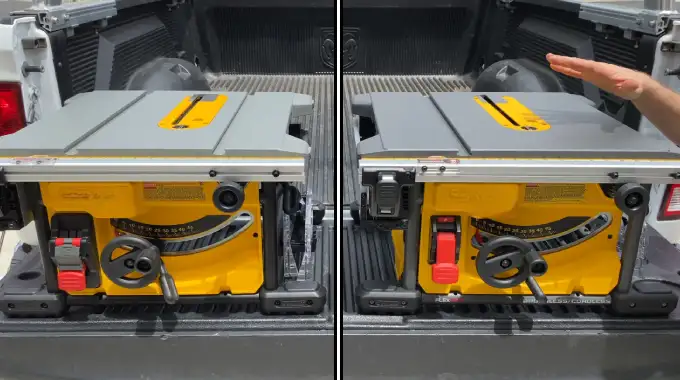

As an individual considering the purchase of a table saw, I recommend understanding the main types of table saws available on the market. There are three basic types: contractor, hybrid, and cabinet table saws.

Contractor table saws are the most affordable option and are designed for on-site use. They typically have a motor that hangs off the back of the saw, making them more portable. However, they may lack some of the features and power of other types.

Hybrid table saws combine the best features of contractor and cabinet saws. They’re more powerful and accurate than contractor saws but also more expensive. Hybrid saws often have a fully enclosed base, improving dust collection and reducing noise.

Cabinet table saws are the top-of-the-line option. They’re heavy-duty, powerful, and highly accurate. The motor is enclosed within the cabinet, resulting in improved dust collection and quieter operation. Cabinet saws are typically found in professional woodworking shops.

Do I need a table saw if I have a miter saw?

While a miter saw is great for cross-cutting and making miter and bevel cuts, a table saw offers a whole new level of versatility.

I found that one of the main advantages of a table saw is its ability to rip cut. With a miter saw, you’re limited to the width of the blade, but with a table saw, you can easily rip boards to any desired width.

Additionally, a table saw can handle various joinery tasks, such as making dado cuts, rabbets, and tenons, which aren’t possible with a miter saw alone.

What size are most table saws?

As far as I know, most table saws commonly use a 10′ blade diameter. This is the industry standard blade size for table saws and is preferred by many professionals and hobbyists. The 10′ blade allows for a good balance between cutting capacity and maneuverability.

It can make precise and accurate cuts while being versatile enough to handle various materials and project sizes without resulting in serious injury. Additionally, a 10′ blade diameter provides a good compromise between cutting depth and portability.

The Table Saw: Unleash Your Woodworking Potential

I hope you now understand that a table saw is an essential tool for any woodworking job. Its versatility and precision make it indispensable for cutting various types of wood and creating precise joints.

While a miter saw can handle some cutting tasks, it lacks the versatility and accuracy of a table saw. As for the size, most table saws are designed to accommodate standard-sized materials.

So, if you want to take your woodworking skills to the next level, investing in a table saw is a must. Trust me, it will revolutionize your woodworking experience like nothing else.