Best Table Saw Ripping Blade: Get Clean Cuts Every Time

If you want precise, smooth cuts with your table saw in 2026, blades like the Freud LU87R010 and Diablo D1024X offer thin kerfs and high-density carbide teeth for fast, clean ripping.

The CMT Orange Tools and Freud LM74R010 give you durability and anti-vibration features, while Amana Tool’s 50-tooth blade handles versatility.

Choosing the right tooth count, kerf, and hook angle matters, and understanding these will help you maximize your saw’s performance and cut quality. Keep exploring to discover the ideal blade for your needs.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Freud LU87R010: 10" Thin Kerf Rip Blade

|

|

|

|

Diablo Ripping Saw Blade for Wood - 10" ...

|

|

|

|

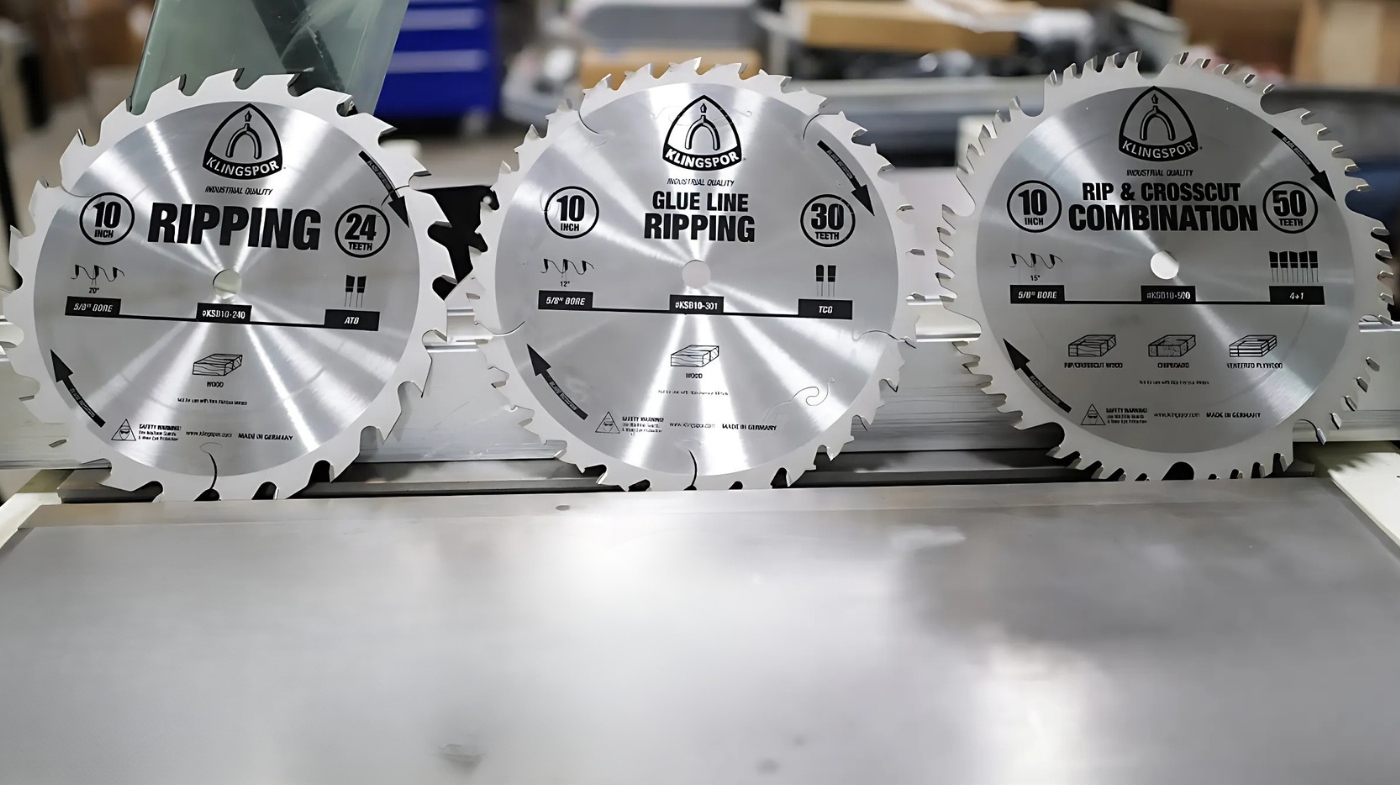

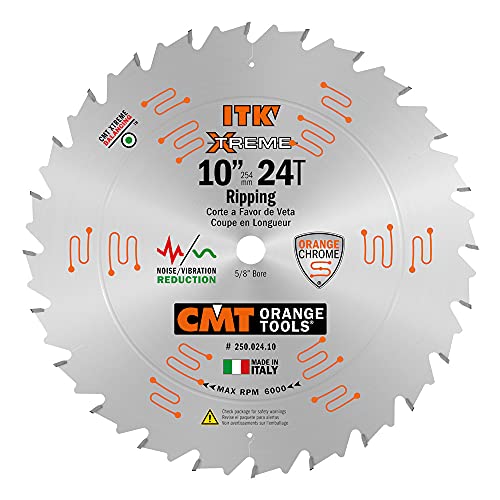

CMT ORANGE TOOLS CMT 250.024.10 ITK Xtre...

|

|

|

|

Freud Industrial Glue Line Ripping Saw B...

|

|

|

|

Amana Tool 610504C Carbide Tipped Presti...

|

|

Key Takeaways

- Choose blades with thin kerf (around .094 inches) for faster feed rates and minimal material waste during ripping cuts.

- Look for premium TiCo HI-Density carbide or micrograin carbide teeth for long-lasting sharpness and heat resistance.

- Blades with 18-30 teeth and flat-top grind are ideal for efficient, smooth ripping with reduced vibration and noise.

- Anti-vibration slots and non-stick coatings enhance cut quality by minimizing noise, friction, and pitch buildup.

- Ensure blade compatibility with your saw’s arbor size (commonly 5/8-inch) and thickness of materials to optimize performance.

Freud LU87R010: 10 Thin Kerf Rip Blade

- Specs: Arbor 5/8", Diameter 10", Grind FLAT, Hook Angle 20°, Kerf .094", Plate .071", Teeth 24

- Premium TiCo HI-Density Carbide Ripping Blend for Maximum Performance

- Thin Kerf allows for faster feed rate and reduced waste

If you need a blade that delivers fast, efficient ripping with minimal waste, the Freud LU87R010: 10 Thin Kerf Rip Blade is an excellent choice.

With its thin kerf design, you’ll enjoy faster feed rates and less material waste, especially on low-horsepower saws.

The 24 large teeth boost cutting efficiency and make sharpening easier, while the premium TiCo HI-Density Carbide guarantees long life and heat resistance.

Its Perma-Shield coating reduces drag and prevents corrosion. You’ll get cleaner cuts, less noise, and reduced vibration—perfect for ripping hardwoods, plywood, and laminates between 3/4” and 2-3/4” thick.

Best For: woodworking enthusiasts and professionals seeking fast, efficient ripping cuts on low-horsepower saws with minimal material waste.

Pros:

- Thin kerf design enables faster feed rates and reduces waste.

- Large 24-tooth design improves cutting efficiency and allows easier sharpening.

- Perma-Shield coating reduces drag, corrosion, and pitch build-up for longer blade life.

Cons:

- Primarily optimized for ripping; crosscutting may result in some surface finish loss outside ideal thickness.

Diablo D1024X 10 24-Tooth ATB Ripping Saw Blade 5/8 Arbor

- High performance TiCo - With Hi-Density carbide specifically designed for each application. Ideal...

- Perma - SHIELD Non-Stick Coating - It provides protection from heat, gumming, & corrosion.

- Super Thin Laser Cut Kerf - For fast, durable, and clean cuts, good for your Remodeling and...

The Diablo D1024X 10-Inch 24-Tooth ATB Ripping Saw Blade is perfect for woodworkers who need a durable, fast, and precise blade for both ripping and crosscutting.

Its super-thin 0.98-inch kerf and alternate-top bevel teeth give you smooth, accurate cuts with less effort. Made from Tico high-density carbide and hardened steel, this blade withstands extreme impacts and heat.

The Perma-Shield coating prevents gumming and corrosion, while laser-cut vents reduce noise and warping. With a 5/8-inch arbor and 7,000 RPM rating, it fits most table saws.

Best For: Woodworkers and construction professionals seeking a reliable, precise, and durable saw blade for ripping and crosscutting various types of lumber and sheet materials.

Pros:

- Super-thin 0.98-inch kerf and ATB tooth design ensure smooth, accurate cuts with less effort.

- Durable construction with Tico high-density carbide and hardened steel withstands extreme impacts and heat.

- Protective Perma-Shield coating and laser-cut vents reduce gumming, corrosion, noise, warping, and maintain blade performance.

Cons:

- 24 teeth may not be ideal for ultra-fine finish cuts compared to blades with higher tooth counts.

CMT ORANGE TOOLS 250.024.10 ITK RIPPING BLADE 10x24x5/8

- For fast rip cuts on soft/hardwood thanks to the thin kerf design.

- To be used on radial arm saws, miter saws, table saws for cutting soft/hardwood. Good on plywood.

- 0.098 kerf thickness, 0.071 plate thickness, 20° Hook Angle, 1 Flat + 2/15° alternate teeth Grind.

Woodworkers seeking fast, precise rip cuts will appreciate the CMT Orange Tools 250.024.10 ITK Ripping Blade’s thin kerf and durable micrograin carbide teeth.

Its 10° hook angle and alternate tooth grind deliver smooth, efficient cuts on both soft and hardwood, including plywood.

The blade’s laser-cut, hardened plate with expansion slots minimizes noise and vibration while resisting heat build-up.

Designed for radial arm, miter, and table saws, it features an anti-kickback design and precision balancing for stability.

Best For: Woodworkers and professionals needing fast, precise rip cuts on soft and hardwood using radial arm, miter, or table saws.

Pros:

- Thin kerf and micrograin carbide teeth provide smooth, efficient cuts with minimal material waste.

- Laser-cut hardened plate with expansion slots reduces noise, vibration, and heat build-up.

- Durable design with anti-kickback features, precision balancing, and multiple resharpening capability.

Cons:

- Requires regular cleaning to maintain cutting efficiency, which may add maintenance time.

Freud LM74R010: 10 Industrial Glue Line Ripping Blade

- Heavy-Duty Construction - Thick kerf and reinforced plate deliver maximum stability and flatness,...

- Premium TiCo Carbide Blend - Features a high-density TiCo ripping blend that maximizes cutting...

- Triple Chip Tooth Design - Specially engineered to deliver exceptionally smooth, true-cut surfaces....

Professionals seeking a reliable ripping blade that delivers both durability and precision will appreciate the Freud LM74R010.

This 10-inch industrial glue line ripping blade features 30 teeth with a 12° hook angle and a thick .118 kerf, ensuring stability and long life.

Its premium TiCo HI-Density Carbide blend maximizes cutting performance, while laser-cut anti-vibration slots minimize vibration for smoother cuts.

You’ll benefit from a crisp, splinter-free finish thanks to the Perma-Shield non-stick coating, which also reduces drag and resists pitch build-up. Designed for industrial efficiency, this blade offers longevity and precise ripping every time.

Best For: Professionals and industrial users seeking a durable, high-performance ripping blade for precise, splinter-free cuts in glue line applications.

Pros:

- Premium TiCo HI-Density Carbide blend ensures maximum cutting performance and longevity.

- Laser-cut anti-vibration slots reduce vibration and blade movement for smoother, precise cuts.

- Perma-Shield non-stick coating minimizes drag, pitch build-up, and corrosion for easier maintenance.

Cons:

- Thicker .118 kerf may result in more material waste compared to thinner blades.

- Specialized design primarily suited for ripping applications, limiting versatility for other cutting tasks.

Amana Tool 610504C Carbide Tipped Circular Saw Blade, 10 Inch, 50 Teeth

- (D) diameter: 10 (250mm)

- Teeth: 50

- (D) Bore: 5/8

If you need a versatile blade that handles both ripping and crosscutting hardwoods with precision, Amana Tool 610504C fits the bill.

This 10-inch, 50-tooth blade features a 15° hook angle and a durable non-stick coating, ensuring smooth cuts with minimal tear-out.

Its combination of flat-top and alternate bevel teeth, along with large gullets, efficiently ejects chips and supports deep cuts.

You’ll appreciate the stiff design that minimizes flex and the sharp carbide tips built for longevity. While it’s not the fastest, it excels on hardwoods like oak and maple, making it a solid, professional-grade choice for versatile woodworking.

Best For: Woodworkers seeking a versatile, durable circular saw blade that performs well on both ripping and crosscutting hardwoods with precision.

Pros:

- Durable carbide tips allow for multiple sharpenings and long-lasting use.

- Combination tooth design with large gullets supports smooth, clean cuts and efficient chip ejection.

- Stiff blade construction reduces flex for accurate cuts and works well with thin stock and zero-clearance inserts.

Cons:

- Slight diameter variations may cause compatibility issues with some table saws.

Freud LM71M010: 10 x 18T Thick Stock Rip Blade

- Specs: Arbor 5/8", Diameter 10", Grind FLAT, Hook Angle 20°, Kerf .153", Plate .118", Teeth 18

- Premium TiCo HI-Density Carbide Ripping Blend for Maximum Performance

- Heavy-Duty Thick Kerf and Plate ensure a stable, flat blade for long cutting life in extreme ripping...

When you need a blade that excels at ripping thick stock between 1-1/2 and 3-1/2 inches, the Freud LM71M010 stands out with its heavy-duty thick kerf and large gullets designed for fast, efficient cuts.

Its premium TiCo HI-Density Carbide teeth guarantee durability, while the Silver I.C.E. coating resists corrosion and heat buildup.

Pretensioned and laser-cut for stability, this 10-inch, 18-tooth blade minimizes vibration and noise, delivering smooth, true cuts.

Whether you’re manual feeding or using a power feeder, Freud’s design handles hardwood and softwood glue joints with ease.

Best For: Professionals and serious woodworkers who need a durable, stable, and efficient blade for ripping thick hardwood and softwood stock between 1-1/2 and 3-1/2 inches.

Pros:

- Durable TiCo HI-Density Carbide teeth ensure long-lasting sharpness and blade life.

- Silver I.C.E. coating reduces corrosion, heat buildup, and pitch accumulation for better performance.

- Pretensioned, laser-cut design minimizes vibration and noise, providing smooth and accurate cuts.

Cons:

- Heavy-duty thick kerf may result in more material waste compared to thin-kerf blades.

- Limited to ripping applications; not suitable for crosscutting or fine finish cuts.

CMT 201.024.10 Industrial Ripping Saw Blade, 10-Inch x 24 Teeth, PTFE Coated

- Application: For for fast, smooth, heavy-duty rip cuts on soft/hardwood. Good performance on plywood

- Machines: To be used on radial arm saws, miter saws, table and special saws

- Technical details: kerf thickness 0126, plate thickness 0087, 20° hook angle, MFLAT Grind

The CMT 201.024.10 Industrial Ripping Saw Blade stands out for delivering fast, smooth rip cuts on both soft and hardwood, making it ideal if you need a reliable blade for heavy-duty woodworking projects.

Its 24 micrograin carbide teeth with a 20° hook angle guarantees clean glue line rips while minimizing kickback. The PTFE coating keeps the blade cool, reduces pitch build-up, and prevents corrosion.

With expansion slots and anti-vibration design, it runs quietly and smoothly. Compatible with various saws, this 10-inch blade offers durability and precision.

Best For: woodworkers and professionals seeking a durable, fast, and smooth ripping saw blade for heavy-duty cuts on soft and hardwood, including plywood.

Pros:

- Fast and smooth rip cuts with clean glue line results due to 24 micrograin carbide teeth and 20° hook angle.

- PTFE coating reduces heat, pitch build-up, and corrosion, extending blade life.

- Anti-kickback shoulder and anti-vibration design enhance safety and reduce noise during operation.

Cons:

- May leave slight tear-out, not ideal for precise flat top grind joint cuts.

- Heavier weight (2 pounds) and thicker kerf may require more power from the saw.

FOXBC 10-Inch Thin Kerf Ripping Table Saw Blade for Wood Cutting

- 10 Inch Thin Kerf Rip Saw Blade, 24-Tooth FTG, Kerf .094", Plate .071", Hook Angle 20°, Wood...

- The blades with high-quality thin kerf and plate for fast, durable, smooth cutting, less vibration...

- Made from high-density tungsten carbide for toughness, wear-resistance, and long life

You’ll appreciate the FOXBC 10-Inch Thin Kerf Ripping Table Saw Blade if you need a durable, smooth-cutting blade that handles hardwood and softwood with ease.

Featuring 24 tungsten carbide teeth, a thin kerf of .094, and a 20° hook angle, it delivers fast, clean cuts with minimal vibration and noise.

It works well on materials from 3/4 to 2-3/4 inches thick, including chipboard and laminates, and excels at dados and rabbets.

Compatible with major 10-inch saws, it offers excellent value and a smooth finish, making it a reliable choice for precise ripping tasks.

Best For: Woodworkers and DIY enthusiasts seeking an affordable, durable, and smooth-cutting 10-inch blade for ripping hardwoods, softwoods, and laminates on compatible table and miter saws.

Pros:

- Made with high-density tungsten carbide teeth for wear resistance and long life.

- Thin kerf design reduces vibration and noise while providing fast, clean cuts.

- Versatile cutting ability for materials 3/4 to 2-3/4 inches thick, including dados and rabbets.

Cons:

- Limited to 24 teeth, which may not be ideal for ultra-fine finish cuts.

FOXBC 10 Inch Combination Saw Blade, 50-Tooth, Wood Cutting, 5/8-Inch Arbor

- 10 Inch 50-Tooth Combination Saw Blade, .098" Kerf, Hook Angle 15°, Plate .071" with 5/8" Arbor,...

- Combination blade is ideal for ripping and crosscutting wood & wood composites with the goal of a...

- Each set of 5 teeth is separated by a large gullet

If you need a versatile blade that excels at both ripping and crosscutting, the FOXBC 10 Inch Combination Saw Blade with 50 teeth is a solid choice.

Its ATB design and high-density FoxCarbide tungsten carbide teeth deliver smooth, precise cuts on hardwoods like cherry and walnut, as well as softwoods. The .098 kerf and large gullets guarantee efficient chip removal and minimal resistance.

Compatible with popular 10-inch saws from DeWalt, Makita, and others, this blade offers professional-quality performance at an attractive price. Users praise its speed and finish, making it ideal for both hobbyists and pros.

Best For: Woodworkers and DIY enthusiasts seeking a versatile, high-quality saw blade for both ripping and crosscutting hardwoods and softwoods.

Pros:

- Durable high-density FoxCarbide tungsten carbide teeth provide long-lasting sharpness and wear resistance.

- Smooth, precise cuts with minimal resistance thanks to the ATB design and .098 kerf.

- Compatible with major 10-inch saw brands such as DeWalt, Makita, and Skil, offering great value for a professional-quality blade.

Cons:

- The 50-tooth configuration may be slower for specialized tasks compared to blades with fewer teeth optimized for ripping.

- May require more frequent cleaning to maintain smooth cuts.

Best Table Saw Ripping Blade: What to Look for Before Buying?

When choosing a table saw ripping blade, you need to focus on key features that directly affect performance, cut quality, and durability. These include:

Blade Material Quality

Choosing a table saw ripping blade starts with understanding the materials that make up its construction. You want a blade made from premium materials like TiCo HI-Density carbide, known for its superior hardness, density, and heat resistance.

Such blades deliver enhanced cutting performance and last longer. Micrograin carbide teeth are another excellent choice—they stay sharp longer and provide smoother cuts due to their fine grain structure.

Look for blades with non-stick coatings like Perma-Shield or PTFE; they reduce friction, prevent pitch buildup, and resist corrosion, extending blade life.

A hardened steel body with shock-resistant brazing boosts durability, helping the blade withstand tough impacts. Additionally, anti-vibration features and expansion slots improve stability, ensuring cleaner cuts and reducing wear during use.

Tooth Count and Design

Although blade material quality sets the foundation, tooth count and design directly affect how your table saw performs during ripping cuts.

Typically, ripping blades have 18 to 30 teeth—fewer teeth like 18 speed up ripping, while more teeth around 30 give smoother finishes.

For ripping, flat-top grind (FTG) teeth are your best bet since they maximize surface contact and cut efficiently.

Avoid alternate top bevel (ATB) teeth here; they’re better suited for crosscutting. The hook angle, usually between 10° and 20°, controls bite aggressiveness—a larger angle feeds faster but may cause tear-out on softer woods.

Match tooth design and count to your material for the best results, and consider micrograin carbide tips to keep your blade sharp and durable longer.

Kerf Thickness Impact

Since kerf thickness determines the width of the cut your blade makes, it plays an essential role in how your table saw performs during ripping.

A thinner kerf, around .094 inches, removes less material, allowing faster feed rates and reducing waste. This is perfect if you’re using a low-horsepower saw or want cleaner cuts with minimal tear-out.

On the other hand, thicker kerf blades, ranging from .118 to .153 inches, offer greater stability and durability, ideal for heavy-duty ripping and thicker stock. Keep in mind that thicker blades need more power to run effectively.

Hook Angle Importance

When you pick a table saw ripping blade, understanding the hook angle can make a big difference in how your cuts turn out.

The hook angle, usually between 10° and 20°, controls how aggressively the blade cuts through wood. A 20° hook angle is ideal for ripping because it pulls the wood into the blade, enabling faster feed rates and smoother cuts in both hardwood and softwood.

However, this angle demands more power from your saw, which can strain the motor. On the other hand, a lower hook angle around 10° is better for crosscutting, offering cleaner edges and less tear-out.

Coating Benefits Explained

If you want your table saw ripping blade to perform consistently and last longer, you should pay close attention to its coating.

Non-stick or PTFE finishes reduce friction and drag, allowing smoother cuts by preventing material from sticking to the blade. These coatings also protect against corrosion and pitch build-up, extending blade life and maintaining sharpness.

By minimizing heat generation during cutting, coatings help prevent warping and preserve both the blade’s and material’s integrity.

Additionally, they enhance wear resistance, so you won’t need to resharpen as often. While coatings can also reduce noise, their primary benefits focus on cutting efficiency, durability, and blade protection.

Vibration and Noise Control

Although vibration and noise are common challenges with table saw ripping blades, you can greatly reduce both by choosing blades designed with anti-vibration features.

Look for blades with laser-cut anti-vibration slots—they minimize sideways movement, giving you smoother, more controlled cuts.

The blade’s weight also matters; heavier blades tend to vibrate less, which helps improve precision. Tooth design plays a role too: flat-top grind (FTG) blades often produce cleaner cuts with less noise compared to alternate top bevel (ATB) blades.

Compatibility With Saws

Reducing vibration and noise is important, but making certain your ripping blade fits your table saw is just as critical for safe and effective cutting.

First, confirm the arbor size matches your saw—commonly 5/8-inch or 1-inch. Next, check the blade diameter; most table saws use 10-inch blades, so using a compatible size is key.

Consider kerf thickness too; thinner kerfs require less power and reduce waste, ideal for low-horsepower saws. Also, verify the tooth configuration fits your needs—a flat-top grind works best for ripping.

Finally, always review the manufacturer’s compatibility guidelines to guarantee the blade’s safe use with your specific saw model.

Frequently Asked Questions

How Do I Safely Change a Table Saw Ripping Blade?

To safely change your table saw ripping blade, first unplug the saw to prevent accidental starts. Use the blade wrench to loosen the arbor nut, holding the blade steady with a piece of wood if needed.

Remove the old blade carefully, then install the new one with teeth facing the right direction. Tighten the arbor nut securely, double-check everything’s in place, and plug the saw back in before use. Safety goggles are a must.

What Maintenance Is Required for Table Saw Blades?

Think of your table saw blade as the heart of your tool — it needs care to keep running strong. You should clean resin and pitch buildup regularly to prevent overheating.

Check for dull or damaged teeth and sharpen or replace the blade as needed. Also, make certain the blade is properly aligned and tightened. Regular maintenance guarantees smooth, precise cuts and extends your blade’s life.

Can These Blades Be Used on Materials Other Than Wood?

You can use table saw blades on materials beyond wood, but it depends on the blade type. Blades designed specifically for wood might not cut metal, plastic, or other materials effectively and could dull or damage quickly. If you want to cut non-wood materials, choose a blade made for those substances, like carbide-tipped blades for metal or specialized plastics blades. Always check the manufacturer’s recommendations before switching materials.

How Do Blade Tooth Count and Design Affect Noise Levels?

If you love your neighbors, you’ll want to contemplate blade tooth count and design carefully. More teeth usually mean less noise because each tooth takes a smaller bite, reducing vibrations.

Fewer teeth can turn your shop into a rock concert—louder and rougher. So, if you’re aiming for a peaceful afternoon, pick blades with higher tooth counts and specialized designs that cut smoothly and quietly, sparing everyone’s eardrums.

Are There Specific Blades Recommended for Left-Handed Users?

You don’t need special blades just because you’re left-handed. Most table saw blades are symmetrical and work the same regardless of hand orientation. Instead, focus on using blades designed for your material and desired cut quality.

However, make sure your table saw’s safety features and controls accommodate left-handed use comfortably. Adjusting your setup and stance will help you work safely and efficiently, no matter which hand is dominant.

Choose Wisely: The Right Ripping Blade Makes All the Difference

Choosing the right table saw ripping blade can transform your woodworking projects. Imagine you’re tackling a hardwood flooring job—using the Freud LU87R010 thin kerf blade means smoother cuts with less waste, saving you time and frustration.

Whether you pick the Diablo for durability or the FOXBC for versatility, the perfect blade helps you work smarter, not harder. Remember, investing in the right blade pays off in precision and efficiency every time you cut.

Last update on 2026-02-09 / Affiliate links / Images from Amazon Product Advertising API