Are Circular Saw Blades Hardened: Behind The Process

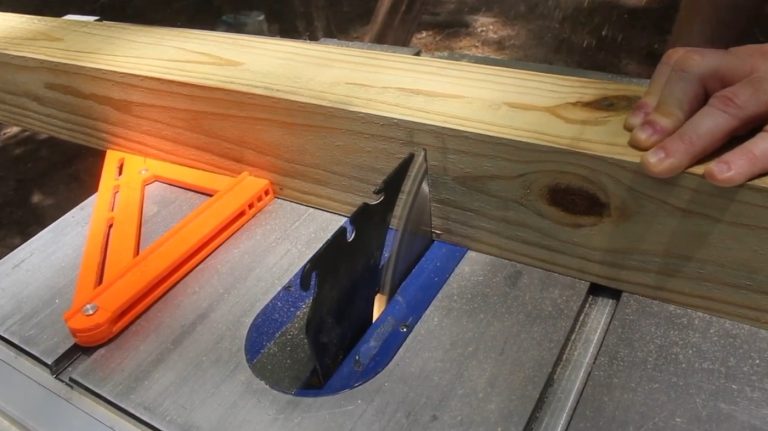

Circular saw blades are handy tools for a range of cutting applications. As they’re used to cut various materials, from wood and metal to plexiglass, you might wonder, “Are circular saw blades hardened?”

According to my findings, circular saw blades are indeed hardened. This is a crucial step in their manufacturing process, as it enhances their strength and durability for various cutting materials. The hardening process involves heating the blade to high temperatures, rapid cooling, reheating, and more.

I will discuss in detail the process for manufacturing and hardening circular saw blades based on my research. So you can gain a better understanding of how these blades are made and why they are hardened.

Why Are Circular Saw Blades Hardened?

Circular saw blades are indeed hardened using a specific manufacturing process like:

- Material selection

- Laser cutting

- Initial heating (Hardening) And rapid cooling (Quenching)

- Tempering (Reheating)

- Straightening and tensioning

- Grinding and polishing

- Tipping

- Sharpening

1. Material Selection

The manufacturing process of circular saw blades begins with the careful selection of the appropriate steel. Depending on the specific application of the saw blade, different types of steel are chosen, such as high-carbon steel or chrome vanadium.

The selection of the steel is vital, as each type offers distinct properties that cater to the blade’s requirements. Tungsten carbide is also an option for saw blades cutting through harder materials, allowing them to be interchangeable depending on their intended use.

2. Laser Cutting

The next step in the process is cutting the shape of the saw blade from the selected steel. To accomplish this, a high-powered CO2 laser is employed for precise cutting.

This technology enables the laser to cut through the metal easily without warping or damaging the edge, ensuring the blade’s shape is accurate. A CAD program determines the design and dimensions of the saw blade, which generates the cutting path for the laser.

3. Initial Heating (Hardening) and Rapid Cooling (Quenching)

After laser cutting shapes from selected steel, the next step in manufacturing and hardening circular saw blades involves heating the blade to high temperatures.

The blade is typically heated to temperatures between 900 and 1,100 degrees Celsius. This high temperature causes the steel’s microstructure to change, making it more suitable for hardening.

Following the initial heating, the blade undergoes rapid cooling, also known as quenching. Quenching is a critical step in achieving the desired hardness of the steel. The rapid cooling helps to lock in the hardened structure of the steel, making it strong and durable.

4. Tempering (Reheating)

After undergoing initial heating and rapid cooling, circular saw blades are further strengthened through the process of tempering.

Tempering involves reheating the blades to temperatures between 350°C and 560°C and then slowly cooling them to ambient temperature. This process is crucial because it reduces the blade’s hardness slightly while increasing its toughness and durability.

By balancing hardness and flexibility, tempering ensures that the circular saw blades can handle the demanding cutting tasks they are designed for.

The reheating step during tempering helps to relieve any residual stresses that may have built up during the initial hardening process. This helps to prevent the blades from becoming overly brittle and ensures that the blades stay sharp for a long time.

5. Straightening and Tensioning

To ensure that the blade runs true and remains aligned during cutting, the blades go through straightening and tensioning processes.

Advanced equipment is employed for this purpose to keep the blade precisely shaped and aligned. This process is essential to achieve optimal cutting performance while minimizing wastage or damage to the material being cut.

6. Grinding and Polishing

The blade is then ground to the required thickness and dimensions. To ensure that the blade meets quality standards accurately, the largest surface grinder is used in this process.

After grinding, the blade goes through automatic polishing to give it a smooth and refined finish. This step emphasizes the blade’s aesthetic, and a smooth finish can benefit the blade’s performance by minimizing friction during use.

7. Tipping

For circular saw blades with tungsten carbide tips, automatic brazing of these tips to the blade body is necessary. Using a computer-controlled induction brazing machine ensures the quality and uniformity of the brazing process.

This process ensures that the tungsten carbide tip and blade body maintain exceptional adhesion, achieving optimum cutting performance.

8. Sharpening

After the initial manufacturing and hardening processes, the blades undergo a sharpening process to ensure optimal cutting performance. A multi-axis CNC machine equipped with diamond wheels is used to perform this process.

The diamond wheels are chosen for their superior hardness and ability to maintain their shape over time. In the grinding machines, the blades are carefully positioned and secured, and diamond wheels are used to remove any imperfections and restore the blades’ sharpness.

This sharpening process is crucial not only for maintaining cutting efficiency but also for versatility, allowing circular saw blades to cut through various materials, including concrete, metal, wood, and plastics.

What is the typical hardness level in circular saw blades?

The typical hardness level of solid High-Speed Steel (HSS) circular saw blades ranges between 58-65 HRC, depending on their intended application. HSS blades with a hardness of 64/65 HRC are commonly used for ferrous cutting, and those with a slightly lower hardness of 58/60 HRC are preferred for non-ferrous cutting.

This high level of hardness provides exceptional resistance to heat and wear, ensuring the circular saw’s teeth stay sharp for longer, resulting in more efficient and effective cutting.

It’s worth noting that the hardness levels may vary based on the type of circular saw blade and the materials they are designed to cut. For instance, tungsten carbide-tipped saw blades have different hardness levels compared to solid HSS blades.

How frequently should you sharpen a hardened circular saw blade?

The frequency of sharpening a hardened circular saw blade largely depends on your usage. If you use your saw infrequently, it’s possible to go a year or more before needing to sharpen it.

However, for regular users, a sharp blade can last a few weeks. It’s recommended to sharpen a standard-width carbide tip blade 2-3 times before it’s ground too much to be used effectively.

As thin kerf blades are smaller, they may only withstand two sharpenings. Sharpening is a cost-effective solution, costing roughly a third of a new blade.

Keep your blades clean, and consider using a high-quality circular saw blade sharpener for optimal results. In short, regularly maintain and sharpen your blade based on your usage to ensure optimal performance.

Take Advantage of the Power of Hardened Circular Saw Blades

It is now clear that circular saw blades are indeed hardened through a meticulously controlled manufacturing process that I shared in detail. This hardening process makes the blades of this power tool more durable, stronger, and wear-resistant, so they can be used for a wide range of cutting jobs.

Precision laser cutting, heating, quenching, tempering, straightening, and grinding increase circular saw blade efficiency and longevity. The hardness of these blades, often reaching 64/65 HRC for ferrous cutting, ensures their cutting edges resist heat and wear. Regular sharpening, based on usage, keeps them performing at their best.