Angle Grinder vs Circular Saw: 8 Key Differences

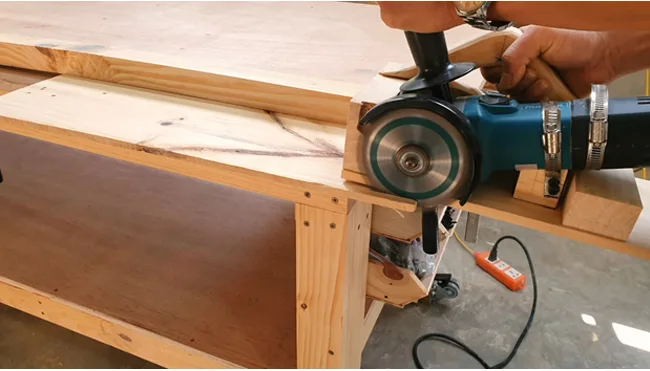

Angle grinders and circular saws are two stalwart tools in the arsenals of DIY enthusiasts and professionals alike. As a DIY enthusiast, I always believe that the right saw for the job makes all the difference. I’m here to explore the age-old debate between angle grinders and circular saws.

Angle grinders are versatile and can cut through various materials with multi-directional cutting. These angle grinders are ideal for rapid material removal. However, circular saws are ideal for straight-line cutting. These saws provide straight-cut stability and are preferred for larger cutting projects.

Both power tools have their advantages, but which one should you choose? Today, I’ll explain the key differences between circular saws and angle grinders and highlight the potential features. So, let’s get started and find out which tool reigns supreme.

- Powerful 6.2 Amp Motor

- Compact and Lightweight Design

- Spindle Lock for Quick Changes

- Left-Mounted Slide Switch for Safety

- Includes 5 Grinding Wheels, Hard Case

- Efficient 5,300 RPM for fast cuts

- Enhances cutting precision

- 51° bevel, positive stop at 45°

- Dust blower ensures clear visibility

- Guarded trigger, power-on indicator for safety

Differences Between Angle Grinder and Circular Saw

I’ve found several key differences when comparing angle grinders and circular saws.

- Blade orientation and cutting angle

- Blade design and safety concerns

- Motor mechanism and tool diameters

- Operational speed

- Ease of operation

- Material specialization

- Mounted or freehand use

- Tool setup and adjustment

1. Blade Orientation and Cutting Angle

The blade on an angle grinder lays flat like a disc parallel to the motor. This design allows for various applications, including grinding, polishing, and cutting through metals, concrete, and wood.

In contrast, the circular saw’s blade is perpendicular to the motor. This configuration is ideal for straight-line cutting and is particularly effective in woodworking.

The circular saw’s perpendicular blade orientation provides stability and precision in straight cuts, while the angle grinder’s flat blade orientation allows for more versatile and multi-directional cutting.

2. Blade Design and Safety Concerns

The blade of an angle grinder, which resembles a flat disc, is not specifically designed for cutting wood. While fitting a saw blade onto an angle grinder may be tempting for added versatility, this practice raises safety concerns. The high-speed rotation of the angle grinder can result in uncontrollability and potential risks.

Alternatively, circular saws are equipped with a variety of blade designs that are optimized for specific materials. Combined with the saw’s configuration, these blades enhance safety and control. Circular saw blades are tailored to the task, providing a more predictable and secure cutting experience.

3. Motor Mechanism and Tool Diameters

An angle grinder’s motor mechanism and abrasive grinding discs enable it to remove material at high speeds. This makes it ideal for tasks that require rapid material removal.

Regarding tool diameters, angle grinders typically have smaller sizes ranging from 4 to 4.5 inches. These compact dimensions allow for detailed and intricate work, making the angle grinder versatile.

On the other hand, circular saws are designed for robust cutting and, therefore, feature larger diameters for their circular blades. With these larger sizes, circular saws are more efficient at cutting through thicker materials, making them the preferred choice for larger woodworking projects.

4. Operational Speed

With its versatile nature, the angle grinder may not excel in speed when cutting wood. Its ability to perform various tasks, such as grinding and polishing, leads to a more deliberate pace.

On the other hand, the circular saw is specifically designed for cutting and is known for its speed in woodwork. With its focused functionality, it allows for quicker and more efficient cuts.

5. Ease of Operation

I find that operating an angle grinder requires more dexterity and precision compared to using a circular saw. While both tools have unique complexities, the angle grinder’s freehand design necessitates a higher level of skill and control.

The angle grinder’s rotating disc allows for versatile applications such as shaping and detailed metalwork. However, this flexibility also demands greater attention to detail and steady hands.

Meanwhile, the circular saw is primarily used for straight-line cuts with its sharp blade, requiring careful setup and accuracy, especially in fixed mode. While preparing the circular saw may take longer, its operation is generally more straightforward and predictable than the angle grinder.

6. Material Specialization

Continuing from the previous subtopic, I’ll now discuss how angle grinders and circular saws differ in their materials.

The angle grinder is primarily designed for working with metals, making it the go-to tool for cutting metal pipes, grinding welds, and shaping various metallic surfaces. While it can occasionally handle wood, its true strength lies in metal and concrete.

As opposed to this, the circular saw is specifically tailored for woodcutting, making it an essential tool for woodworking projects. Although it can also be used with other materials depending on the blade, its true prowess and versatility are best showcased in woodwork.

7. Mounted or Freehand Use

When using an angle grinder or a circular saw, one must consider whether to use them mounted or freehand. The angle grinder, designed for freehand use, offers flexibility and mobility. Its handheld design allows for easy navigation of various angles and contours, making it well-suited for intricate work.

Meanwhile, the circular saw is typically employed in a fixed position, prioritizing stability and precision. While handheld models exist for smaller cuts, the fixed mode provides heightened accuracy, particularly for longer straight cuts.

Choosing between mounted or freehand use depends on the specific task at hand. Mounted use is ideal for projects that require stability and precise cuts, while freehand use allows for greater maneuverability and versatility.

8. Tool Setup and Adjustment

After considering the mounted or freehand use of an angle grinder or circular saw, the next important aspect to compare is the tool setup and adjustment. Regarding the angle grinder, its handheld design allows for quick and easy setup. There are minimal adjustments needed, if any, before it’s ready for use.

In contrast, the circular saw requires a more deliberate setup process. Adjusting the saw’s base or guard for depth and angle is crucial for achieving precision in cutting. This added preparation makes the circular saw a tool that benefits from a more structured approach.

Angle Grinder vs Circular Saw: Comparison Table

| Aspect | Angle Grinder | Circular Saw |

| Blade Orientation and cutting angle | Parallel to the motor, like a flat disc enabling diverse cuts. | Perpendicular to motor, facilitating straight-line cuts. |

| Ease of Operation | Handheld, ready to use for freehand tasks. | Requires setup, especially in fixed mode, for precision cuts. |

| Material Specialization | Primarily for metals, versatile for other surfaces. | Woodcutting prowess with the ability to cut other materials. |

| Blade Design and Safety | Flat disc design; caution needed for wood cutting. | Diverse blade designs for safety and material-specific applications. |

| Motor Mechanism and Diameter | High-speed with smaller diameters (4-4.5 inches). | Robust cutting with larger blade diameters for efficiency. |

Angle Grinder or Circular Saw: How to Choose the Right One?

When deciding between an angle grinder and a circular saw, there are several factors to consider.

Identify the Project Requirements

To determine the right tool for the job, I advise assessing the specific project’s requirements and determining whether an angle grinder or a circular saw would be most suitable.

The first step is to define the specific task at hand. Is it primarily cutting, grinding, or polishing, or a combination of these activities? This will help you understand the tool’s necessary capabilities.

Next, consider the material I’ll be working with. Wood, metal, and concrete have different characteristics and require different tools for optimal results.

Lastly, evaluate the intricacy of the job. If precision and finesse are required, a circular saw may be better. However, an angle grinder may be the more appropriate option if the project involves removing excess material quickly and efficiently.

Evaluate Precision and Accuracy

The circular saw is often the preferred choice for straight cuts in woodworking. Its larger blade diameter and adjustable cutting depth provide better control and accuracy for these types of cuts.

Alternatively, the angle grinder offers more flexibility and adaptability, making it suitable for tasks with less critical precision. Its smaller blade diameter and handheld design allow it to maneuver in tight spaces.

However, note that the angle grinder may not provide the same level of precision as the circular saw.

Evaluate Setup Time

To determine the optimal tool for your project, consider the setup time required when choosing between an angle grinder and a circular saw.

The setup time for an angle grinder is minimal due to its freehand design. This allows for immediate action as soon as the tool is turned on.

Conversely, a circular saw may require more planning and setup. Fixed-position cuts with high precision may necessitate clamps, guides, or other accessories to ensure accuracy. These additional setup steps can take some time but are necessary for achieving precise cuts.

Consider Tool Size and Weight

When considering the right tool between an angle grinder and a circular saw, I found it crucial to factor in the size and weight. Both tools have their advantages and disadvantages in this regard.

Angle grinders are generally more compact and handheld, making them easier to maneuver in tight spaces. They’re also lighter, which can benefit extended use or when working overhead.

In contrast, circular saws tend to be bulkier, especially for larger models. This can make them more challenging to handle and transport. However, a circular saw’s larger size and weight often translate to increased power and cutting capacity, making them better suited for larger projects.

Can I use an angle grinder as a circular saw?

As found in my study, you can achieve similar cutting results using an angle grinder as a circular saw. While angle grinders aren’t specifically designed for cutting wood, they can still be used effectively with the right blade and technique.

One important consideration is the type of blade to use. Selecting a blade specifically designed for cutting wood is crucial, as using the wrong type of blade can be dangerous and lead to kickback. Moreover, ensure that the angle grinder is securely held and properly supported during cutting.

What should you not cut with an angle grinder?

While achieving the same cutting results with an angle grinder as a circular saw is possible, certain materials shouldn’t be cut with an angle grinder.

It isn’t recommended to cut stones and concrete with an angle grinder. This is because angle grinders aren’t designed for this type of cutting and may cause damage to the tool or pose a safety risk.

Stones and concrete are dense and hard materials that require specialized tools, such as masonry saws or diamond blades, for accurate and efficient cutting. Attempting to cut these materials with an angle grinder may result in uneven cuts, chipping, or cracking, potentially harming the user.

Are there cordless options for angle grinders?

The use of cordless angle grinders provides convenience for users, as they offer greater mobility and are suitable for DIY projects and tasks that require limited power sources. With advancements in battery technology, cordless angle grinders have become a popular choice among DIY enthusiasts and professionals alike.

These cordless tools eliminate the need for a power outlet, allowing users to work in remote locations or areas without electricity access. They’re also more portable, making maneuvering and working in tight spaces easier. Also, cordless angle grinders typically come with rechargeable batteries, ensuring uninterrupted usage.

Can I cut metal with a circular saw?

I recommend using a blade specifically designed for metal cutting when using a circular saw to cut metal. This blade type features teeth designed to handle metal rigidity and hardness. These blades are typically made from carbide or high-speed steel, giving them durability and strength.

When operating a circular saw to cut metal, ensure the blade is securely attached and properly aligned. Aside from that, use appropriate safety measures, such as wearing protective eyewear and gloves, as cutting metal can produce sparks and debris.

Choose Wisely: Angle Grinder or Circular Saw for the Perfect Cut

Consider the specific cutting task when choosing between a circular saw and an angle grinder. Both tools have advantages and disadvantages, but ultimately, the decision should be based on the material cut and the desired outcome.

While an angle grinder may offer more versatility and power for cutting or grinding, a circular saw can provide more precision and control for cutting wood or other materials.

So, carefully evaluate your needs along with the differences I discussed above to choose the tool that best suits your requirements. Be mindful that deciding between these tools isn’t easy, but you can easily cut through any project with proper consideration.

- Brushless Motor for Extended Life

- Quick 2-Second Wheel Brake

- Kickback Brake for Safety

- E-Switch Protection for Power Outages

- Two-Stage Trigger for Activation Safety

- Lightweight Design: Weighs only 8.8 lbs.

- Powerful 15 Amp Motor: Handles tough applications.

- Quick Electric Brake: Stops blade promptly.

- Versatile Beveling: 57-degree bevel capacity.

- Durable Construction: High-grade Aluminum smooth base.

Last update on 2026-02-26 / Affiliate links / Images from Amazon Product Advertising API