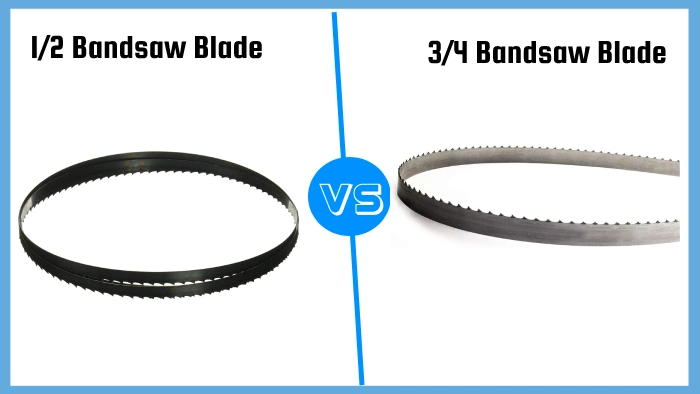

1/2 vs 3/4 Bandsaw Blade: 8 Differences

Selecting the appropriate bandsaw blade is a critical decision for woodworkers, influencing their cutting operations’ precision, efficiency, and versatility. Among the myriad choices, I think the dilemma often boils down to the decision between a 1/2″ and 3/4″ blade.

The 3/4″ blade boasts a superior cutting capacity for denser materials, while the 1/2″ delivers fast and smooth cuts for thinner or softer surfaces. Both blades provide professionals with a dependable tool for any project.

Besides their cutting capacity, several other significant differences exist between 1/2″ and 3/4″ bandsaw blades. These differences include tensioning and resawing capabilities, wheel width, versatility and more.

Here, I will dive deeper into these differences and provide guidance on which blade size to choose for specific cutting needs. After reading this article, you’ll have a clearer picture of which blade size suits your needs, ensuring smooth, precise, and enjoyable woodworking experiences.

- High silicon, low carbide steel

- Low tension, less horsepower needed

- Cool running, prolonged lifespan

- Ideal for resawing thick stock

- Unique 6.5-degree tooth angle

- Premium high-grade carbon steel construction

- Heat resistant for enhanced durability

- Optimal geometric tooth design

- Suitable for multiple band saws

- Precise cutting for various materials

8 Differences Between 1/2 and 3/4 Bandsaw Blade

According to my findings, the bandsaw blade’s size is crucial to the wood-cutting performance. Here I listed the significant differences between the two most commonly used bandsaw blade sizes, 1/2″ and 3/4″.

- Blade stability and flexibility

- Cutting efficiency and feed rate

- Tensioning challenges and saw compatibility

- Resawing capabilities and kerf size

- Motor power and blade width compatibility

- Wheel width and blade size interaction

- Versatility and specialized applications

- Cost and blade longevity

No 01: Blade Stability and Flexibility

The choice between a 1/2′ and 3/4′ bandsaw blade significantly impacts the stability and flexibility of your woodworking cuts.

A 3/4′ blade offers more stability in straight-line cuts due to its larger size and increased resistance to deflection. This makes it ideal for cutting thicker materials or making long, straight cuts.

On the other hand, a 1/2′ blade provides greater flexibility, allowing for tighter curves and intricate cuts. This makes it suitable for projects that require more maneuverability and the ability to make intricate shapes.

No 02: Cutting Efficiency and Feed Rate

To further explore the differences between a 1/2′ and 3/4′ woodworking bandsaw blade, let’s now focus on the subtopic of cutting efficiency and feed rate.

The cutting efficiency and feed rate vary between these two blade sizes. A 3/4′, with its larger surface area and tooth engagement, often results in higher cutting efficiency. This means it can cut through materials more effectively and with less effort.

Conversely, a 1/2′ blade may have a faster feed rate due to reduced friction and a smaller contact area. This allows for quicker cutting, but it may sacrifice some efficiency.

No 03: Tensioning Challenges and Saw Compatibility

Regarding tensioning, 3/4′ blades can pose difficulties on certain bandsaw models. Achieving proper bandsaw blade tensioning may prove challenging, leading to potential tracking and overall performance issues.

In contrast, 1/2′ blades are generally more forgiving regarding tensioning requirements. They offer greater versatility and compatibility with a broader range of bandsaws. This makes them a reliable choice for woodworkers with different bandsaw models in their workshops.

No 04: Resawing Capabilities and Kerf Size

The width of the blade plays a crucial role in determining the effectiveness of resawing and the size of the kerf.

A 3/4′ blade is ideal for resawing tasks as it provides greater depth and stability, making it easier to cut through thicker stock. On the other hand, a 1/2′ blade may not offer the same resawing capabilities but compensates with a narrower kerf, resulting in less material wastage.

The choice between the two depends on your priorities, whether you prioritize resawing or minimizing kerf size. Consider your specific needs to determine which blade width is best suited for your woodworking projects.

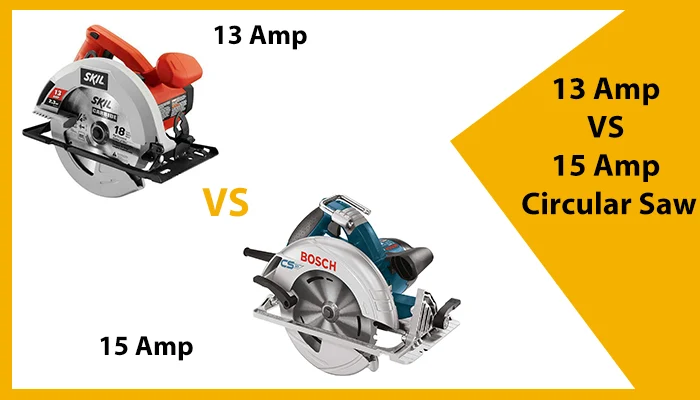

No 05: Motor Power and Blade Width Compatibility

Motor power plays a significant role in determining the effectiveness of the bandsaw blade. Higher horsepower bandsaws are better suited for handling 3/4′ blades, as they can leverage the increased size for efficient cutting.

Alternatively, bandsaws with lower horsepower are more forgiving with 1/2′ blades, making them suitable for machines with varying motor capabilities.

Matching the blade width with the motor power is important to ensure optimal performance and avoid strain on the bandsaw motor.

No 06: Wheel Width and Blade Size Interaction

The width of the wheels plays a significant role in accommodating the size of the blade and minimizing the risk of blade deflection. A 3/4′ blade may require wider wheels to provide adequate support and stability during operation.

Meanwhile, a 1/2′ blade is more versatile and can work with narrower wheels, allowing greater flexibility in choosing bandsaws with different wheel configurations.

No 07: Versatility and Specialized Applications

The versatility of 1/2′ and 3/4′ woodworking bandsaw blades varies, impacting their suitability for specialized applications. A 1/2′ blade offers greater flexibility and a smaller kerf, making it ideal for intricate cuts and curved designs. Its versatility allows for a wide range of woodworking tasks.

As opposed to this, a 3/4′ blade excels in re-sawing tasks but may be less suitable for intricate details due to its larger size and wider kerf. When choosing between the two, I recommend considering the primary focus of your woodworking projects.

In addition, consider how complex it will be to store bandsaw blades with different sizes. If versatility across applications is crucial, a 1/2′ blade is recommended. However, if specialization in specific cutting tasks, such as re-sawing, is your priority, then a 3/4′ blade would be more suitable.

No 08: Cost and Blade Longevity

Considering the economic aspect of blade selection, cost and blade longevity are crucial in determining the differences between 1/2′ and 3/4′ woodworking bandsaw blades.

In terms of cost, 1/2′ blades are generally more affordable compared to their 3/4′ counterparts. However, it’s important also to consider the longevity of the blade.

While a 3/4′ blade may have a higher upfront cost, its durability and extended lifespan can offset the initial expense. Therefore, users must carefully weigh cost considerations against long-term value and performance expectations when choosing between the two blade sizes.

It’s advisable to assess the specific needs of your woodworking projects and decide based on a balance of cost and blade longevity.

Comparison Table Between 1/2 and 3/4 Bandsaw Blade

| Aspect | 1/2″ Blade | 3/4″ Blade |

| Blade Stability and Flexibility | Offers greater flexibility for intricate cuts. | Provides more stability in straight-line cutting. |

| Cutting Efficiency and Feed Rate | Faster feed rate with reduced friction. | Higher cutting efficiency due to larger surface. |

| Tensioning Challenges and Compatibility | More forgiving, and compatible with various saws. | This may pose tensioning challenges on certain models. |

| Resawing Capabilities and Kerf Size | Limited in resawing depth; narrower kerf. | Excels in resawing with greater depth; and wider kerf. |

| Motor Power and Compatibility | Suitable for lower horsepower bandsaws. | Requires higher horsepower for optimal performance. |

| Wheel Width and Interaction | Adaptable to narrower wheels. | May require wider wheels to reduce blade deflection. |

| Versatility and Specialized Applications | Versatile for intricate cuts and curved designs. | Specialized for resawing, less versatile overall. |

| Cost and Blade Longevity | Generally more cost-effective. | Higher upfront cost, potentially longer lifespan. |

Precision or Power: Decode the Choice Between 1/2″ and 3/4″ Bandsaw Blades

As you can see, the differences between a 1/2 and 3/4 woodworking bandsaw blade are significant. The 1/2 blade offers more precision and is suitable for intricate cuts, while the 3/4 blade provides greater stability and is ideal for heavy-duty tasks.

The distinctions in stability, efficiency, and compatibility underscore the importance of aligning the blade choice with the intricacies of the intended woodworking tasks.

In my opinion, the choice between these two blades depends on the user’s specific woodworking needs and preferences. It’s crucial to consider the desired outcome and the type of wood used before deciding.

- Precision-milled teeth for aggressive cutting

- High carbon steel construction

- Compatible with JWBS-14SFX bandsaw

- Match tooth welded and hardened

- Genuine JET parts for reliability

- Precision-sharpened teeth for intricate cutting

- Premium Japan SK8 carbon steel

- Superior hardened and tempered material

- Fits 14″ Delta/Rockwell, Grizzly, Jet, and more

- Direct-to-you approach for affordability

Last update on 2026-01-28 / Affiliate links / Images from Amazon Product Advertising API