Do Table Saws Have Guards: Behind the Reasons

As a woodworker, you probably have a fair share of close calls with table saws. You know, those heart-stopping moments when you think your finger might just become a permanent part of your latest project. Safety is always the priority when working with machinery, and that’s where table saw guards come in.

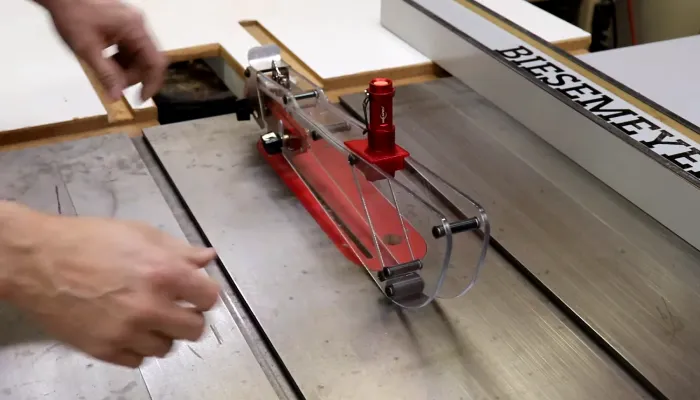

According to my research, table saws must have blade guards when cutting or ripping. Guards prevent accidental contact with the saw blade, reducing the risk of serious injuries. They help prevent kickback, which occurs when the wood gets caught and thrown back at the operator.

Here, I’ll discuss why table saw guards are so important. You will also find here how to install and more. Let’s explore the fascinating world of table saw guards and uncover their true purpose.

Why Do Table Saws Have Guards: 8 Reasons

I believe, when using a wood cutting table saw, it’s essential to have guards in place for several reasons.

- Prevention of accidental contact

- Kickback prevention

- Woodchip and debris management

- Dust collection

- Operational stability and balance

- Protection against thrown wood

- Enhanced safety for small pieces

- Legal and regulatory compliance

No 1. Prevention of Accidental Contact

As far as I know, the guard’s main purpose on a wood-cutting table saw is to ensure your safety by preventing accidental contact with the spinning blade. It acts as a physical barrier, creating a safe distance between me and the sharp edges and teeth of the blade.

Accidental contact with a spinning blade can result in serious injuries, such as deep cuts, amputations, or even fatalities. The guard is crucial in reducing the risk of such accidents, especially when working with different materials or making intricate cuts.

Remember, you should not use gloves when using a table saw for woodworking projects.

No 2. Kickback Prevention

Kickback is dangerous when the wood is forcefully propelled backward, posing a significant risk to the user and bystanders. By keeping the workpiece aligned and preventing it from pinching the blade, these guards help mitigate the risk of kickback.

The use of a riving knife or splitter with blade guards ensures the material is guided through the blade, reducing the chance of being caught or thrown back. I believe this protects the user from potential injuries and helps maintain a safe working environment.

No 3. Woodchip and Debris Management

When using a table saw, wood chips and debris can be produced at a high rate, and without proper management, they can pose a significant risk. Guards help to contain and redirect these wood chips and debris away from the operator, reducing the chances of them causing distractions or interfering with the cutting process.

By keeping the work area cleaner, guards also contribute to a safer working environment by preventing slips and falls.

Also, effective woodchip and debris management help improve visibility during cuts, allowing operators to have a clear view of the material and cutting area.

No 4. Dust Collection

Managing dust collection is essential for powerful wood-cutting table saws, ensuring the workspace’s cleanliness and efficiency while promoting the saw’s longevity. If I am not wrong, dust generated during cutting can pose several problems if not properly managed.

It can accumulate around the blade and motor components, leading to decreased performance and potential damage. Additionally, airborne dust particles can pose health risks to the operator if inhaled.

To address these concerns, many blade guards are designed to facilitate dust collection at the source. These guards often feature built-in dust ports or attachments that can be connected to a dust collection system.

They help maintain a clean and safe work environment while enhancing the overall efficiency and lifespan of the saw by capturing dust at the source.

No 5. Operational Stability and Balance

According to my findings, using wood-cutting table saw guards significantly contributes to the operational stability and balance of the saw. The presence of a guard helps maintain a consistent distance between the blade and the material being cut, which is crucial for smooth operation.

By reducing vibrations, guards enhance control and allow for accurate cuts. Without a guard, the saw is more prone to tipping or vibrating unexpectedly, compromising the entire machine’s stability and balance. As a result, the quality of cuts can be affected, and the operator is also at risk of injury.

No 6. Protection Against Thrown Wood

The guard on the wood cutting table saw protects against thrown pieces of wood. When cutting wood, there’s a risk that the force of the blade can cause small or large pieces of wood to be forcefully ejected from the machine. These thrown pieces of wood can harm the operator, potentially causing injuries or accidents.

Having a guard in place acts as a shield, preventing these cut-off pieces or offcuts from being thrown back toward the operator. Working with irregularly shaped or prone to splintering materials requires this protective feature to minimize the risk of being struck by flying wood pieces.

No 7. Enhanced Safety for Small Pieces

I found that wood-cutting table saws have guards to enhance the safety of working with small pieces. When handling small or narrow workpieces, there’s a higher risk of the operator’s hands getting too close to the blade.

The blade guard helps to secure and guide these smaller pieces, reducing the chances of accidents and injuries. Additionally, the guard ensures that the small pieces are properly aligned and positioned for cutting, improving accuracy and precision.

No 8. Legal and Regulatory Compliance

Many jurisdictions and workplace safety regulations mandate the use of safety guards on industrial equipment, including table saws. Employers and individuals are legally obligated to maintain and use guards properly. Failure to comply with these regulations can result in legal consequences and penalties.

Can a blade guard impact the accuracy of my cuts?

Installing a blade guard on a table saw doesn’t significantly impact the accuracy of cuts when properly installed and adjusted. In fact, a properly installed and adjusted blade guard can actually contribute to the stability and control of the saw, resulting in more accurate cuts.

However, if you have any problems with cut accuracy after installing a blade guard, I recommend ensuring the guard is aligned correctly.

Why do some woodworkers prefer not to use blade guards?

Some woodworkers choose to forgo blade guards because they believe it restricts their flexibility and increases the risk of accidents.

They argue that blade guards can limit their visibility and hinder their ability to maneuver the wood during certain specialized cuts, such as dados or rabbets. They believe they have better control and precision over their cuts by removing the guard.

However, it’s important to note that removing the blade guard does come with inherent risks. Woodworkers who choose not to use blade guards should be highly experienced and take extra precautions to ensure their safety.

Use Blade Guards: Minimize Table Saw Accidents

According to what I discussed above, guards are important in ensuring safety and preventing accidents on wood cutting table saws. While some woodworkers may prefer not to use them for various reasons, it’s important to prioritize safety over convenience.

The multifaceted role of blade guards in preventing injuries and kickbacks and ensuring a clean working environment underscores their significance.

Using blade guards, we can protect ourselves from injuries and create a more secure working environment. So, when using a table saw, always prioritize safety.